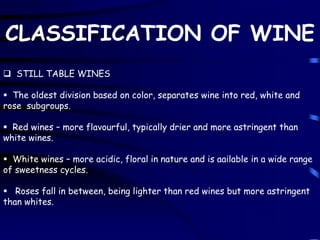

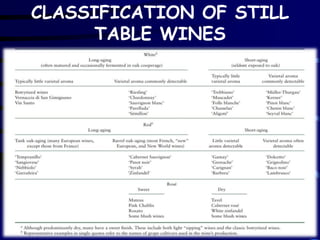

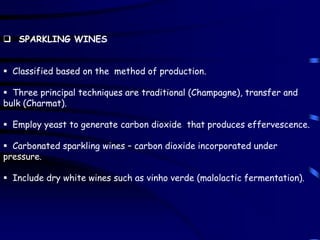

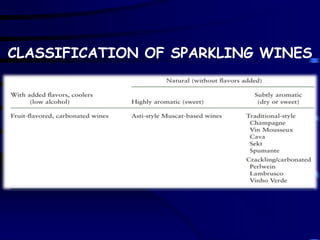

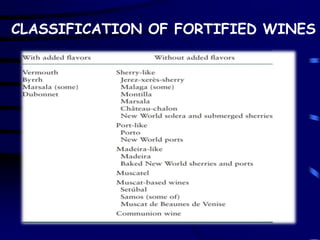

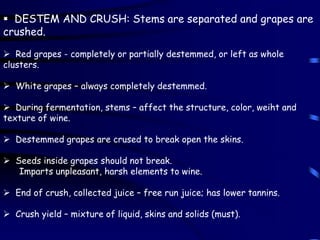

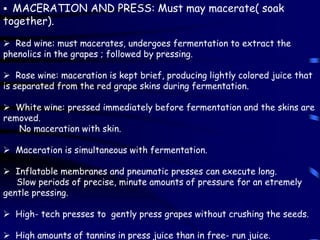

The document provides an overview of microbial biotechnology in wine production, highlighting key processes like fermentation, classification of wines, and health benefits associated with wine consumption. It details methods for producing still, sparkling, and fortified wines, emphasizing the role of various grape preparation techniques, fermentation conditions, and aging processes that influence the final product's flavor and characteristics. Historical context is also included, tracing wine's origins and cultural significance throughout time.