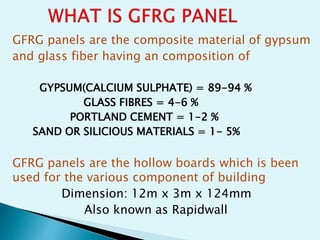

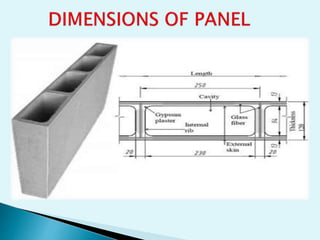

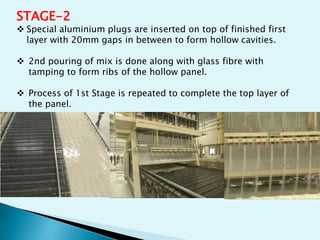

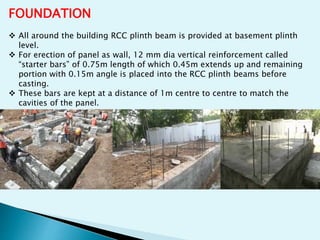

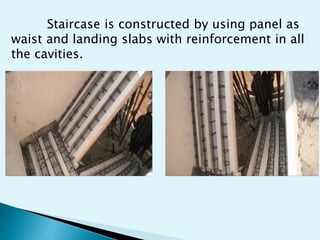

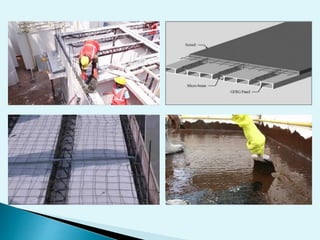

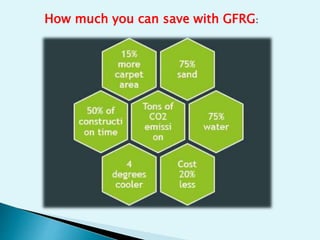

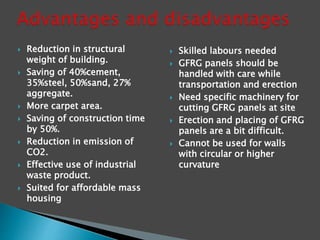

This document discusses glass fiber reinforced gypsum (GFRG) panels, which provide a fast construction technology for affordable housing. GFRG panels are composed mainly of gypsum, with glass fibers, cement, and sand added. They are hollow boards that are lighter and stronger than concrete, with benefits like reduced construction time and costs. The document describes the manufacturing process of GFRG panels and how they are used in building foundations, walls, roofs and stairs. It is noted that GFRG panels can help address India's shortage of housing while making use of industrial gypsum waste, providing savings of up to 30% in construction costs.