The document summarizes India's energy efficiency policy and the Bureau of Energy Efficiency's initiatives. Key points include:

1) India's energy consumption has risen with economic growth, putting pressure on scarce resources. The Energy Conservation Act of 2001 established the Bureau of Energy Efficiency to promote efficiency.

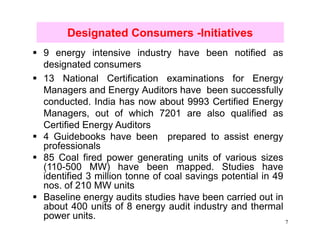

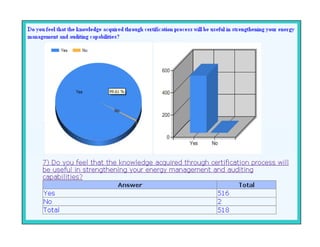

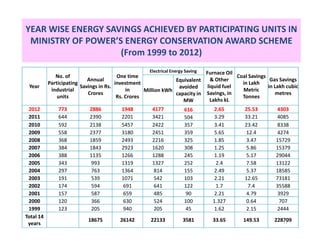

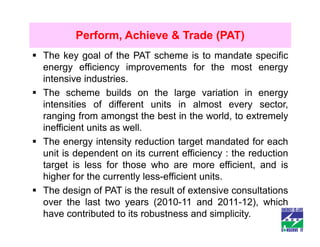

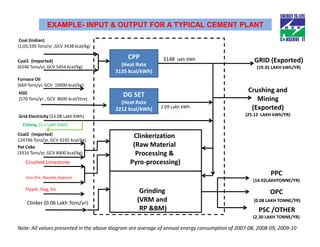

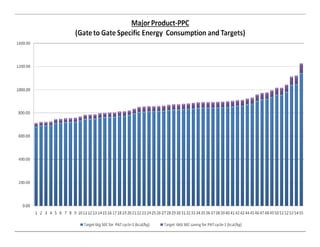

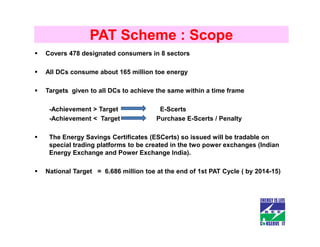

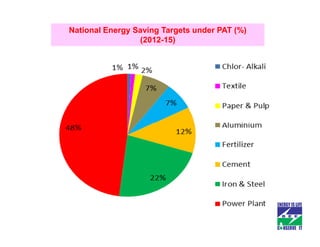

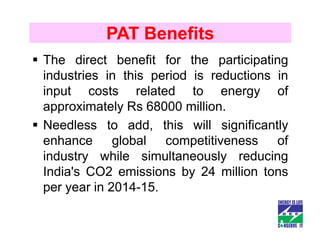

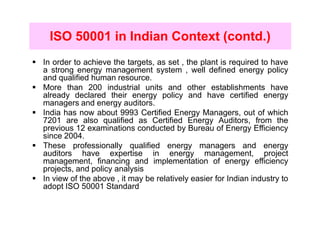

2) The Bureau designates energy-intensive industries as "designated consumers" required to appoint energy managers, conduct audits, and meet efficiency standards. It has certified over 9,000 energy managers and auditors.

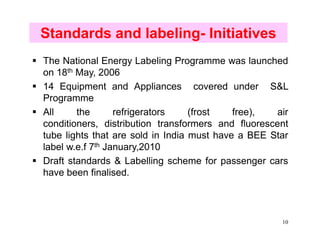

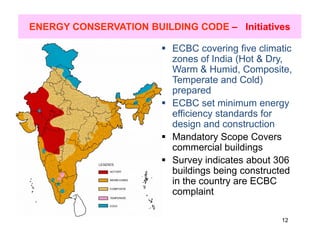

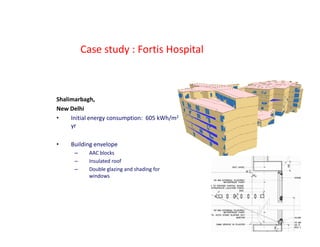

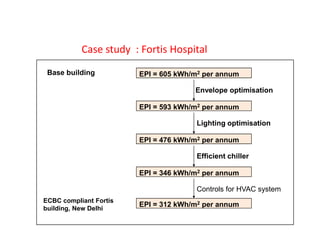

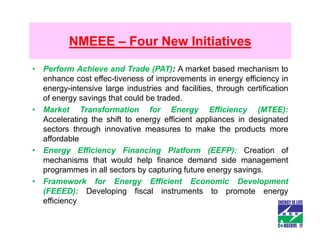

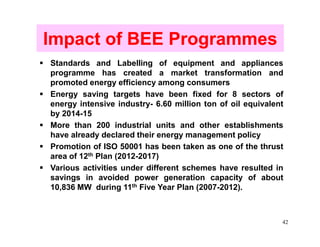

3) Standards and labeling programs require efficient appliances. The Energy Conservation Building Code sets efficiency standards for new commercial buildings. Initiatives include codes, awards, and efficiency recommendations for power plants.