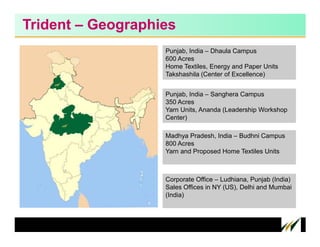

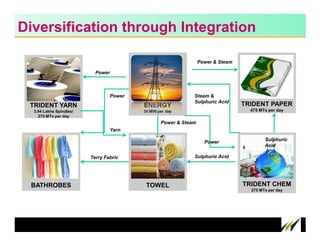

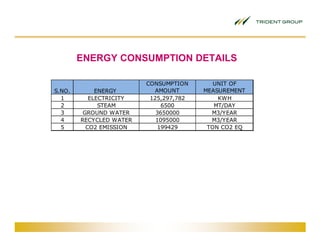

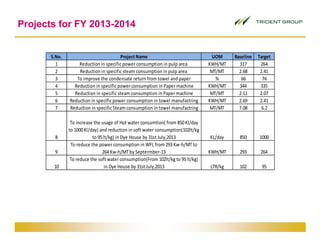

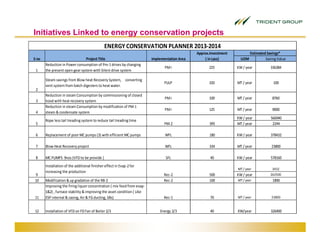

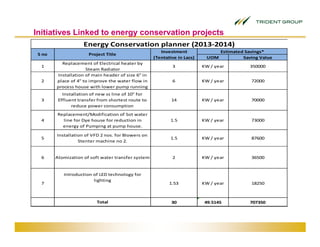

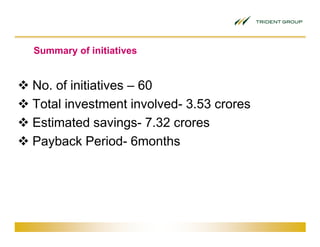

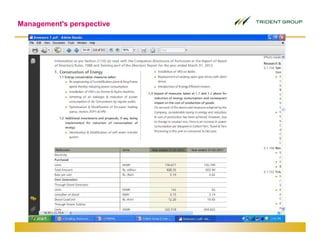

Trident Group operates textile manufacturing campuses across India with a total land area of over 1750 acres. It has yarn, home textiles and paper manufacturing units. The company has proposed multiple energy conservation projects for 2013-2014 focused on reducing power, steam and water consumption across its operations. Key initiatives include improving heat recovery systems, installing variable frequency drives and more efficient pumps and motors. The total investment is estimated at 3.53 crores with projected annual savings of over 7 crores and a payback period of 6 months.