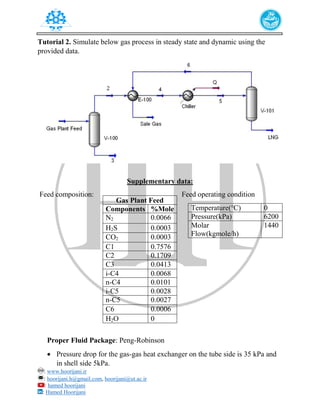

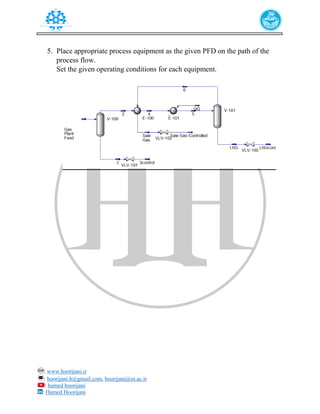

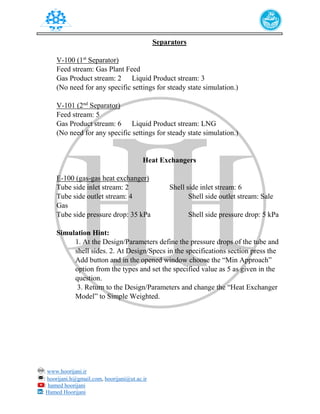

This document provides a tutorial for simulating a gas process system in steady state and dynamic mode using Aspen HYSIS. It includes process specifications, operating conditions, equipment details, and controller settings. The tutorial instructs the user to: 1) build the steady state process model and solve it; 2) add PID controllers to control liquid level and pressure; and 3) use the Dynamic Assistant to simulate the dynamic behavior of the system over time.