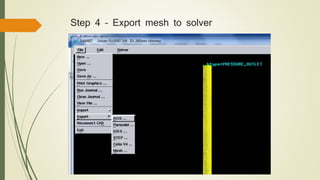

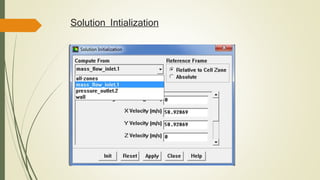

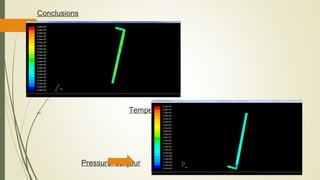

This document summarizes a training seminar on solving fluid flow problems using CFD software. The seminar was held at the Centre For Fire, Explosive & Environmental Safety (CFEES) under DRDO. The seminar covered an introduction to CFD modeling strategies and objectives to solve (1) hydraulic pipe network problems using Flowmaster software and (2) combustion gas flow through an exhaust duct of a lab-scale facility using Flowmaster and Fluent. The document provides details on modeling steps, input parameters, and results for both objectives.