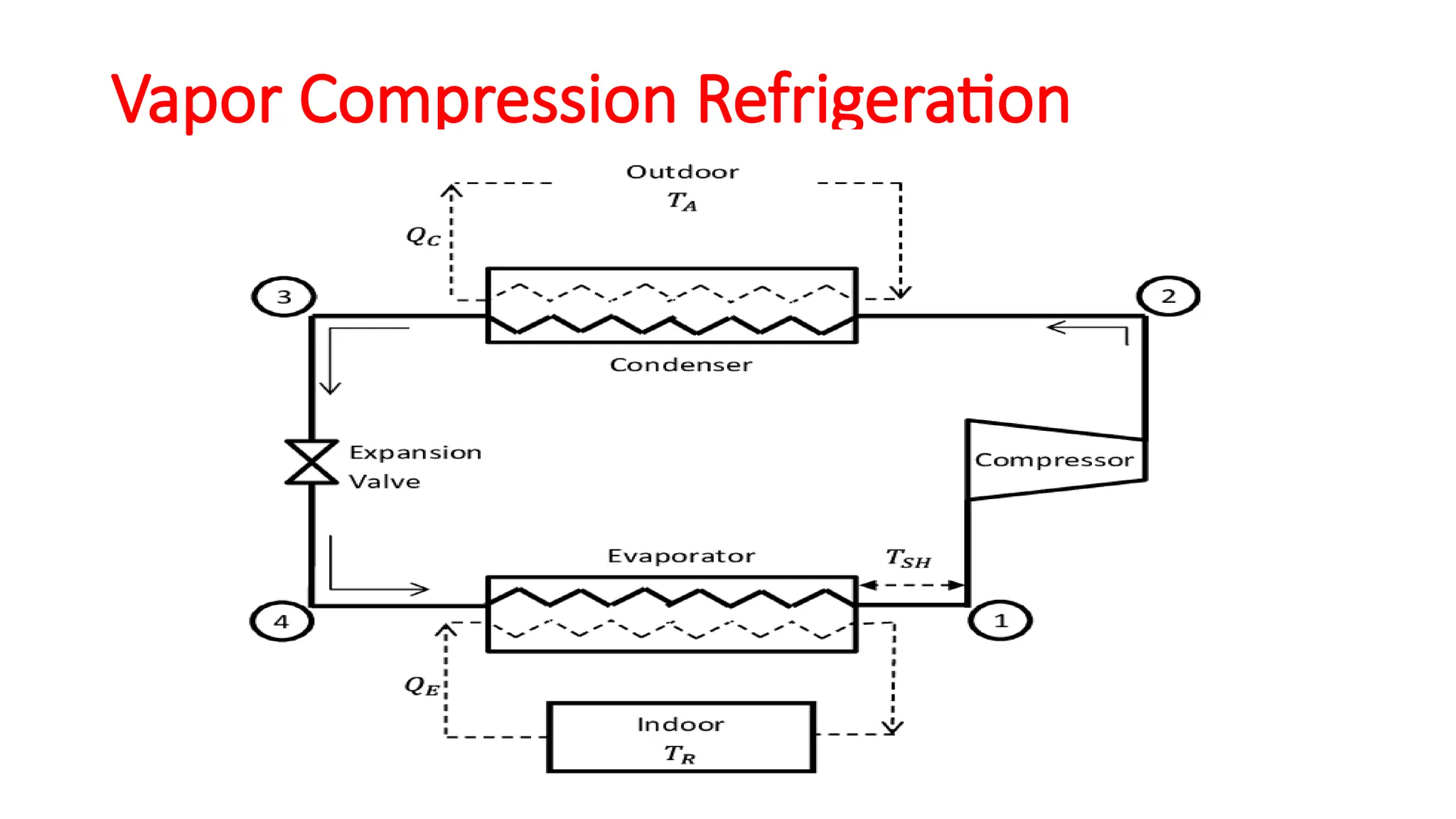

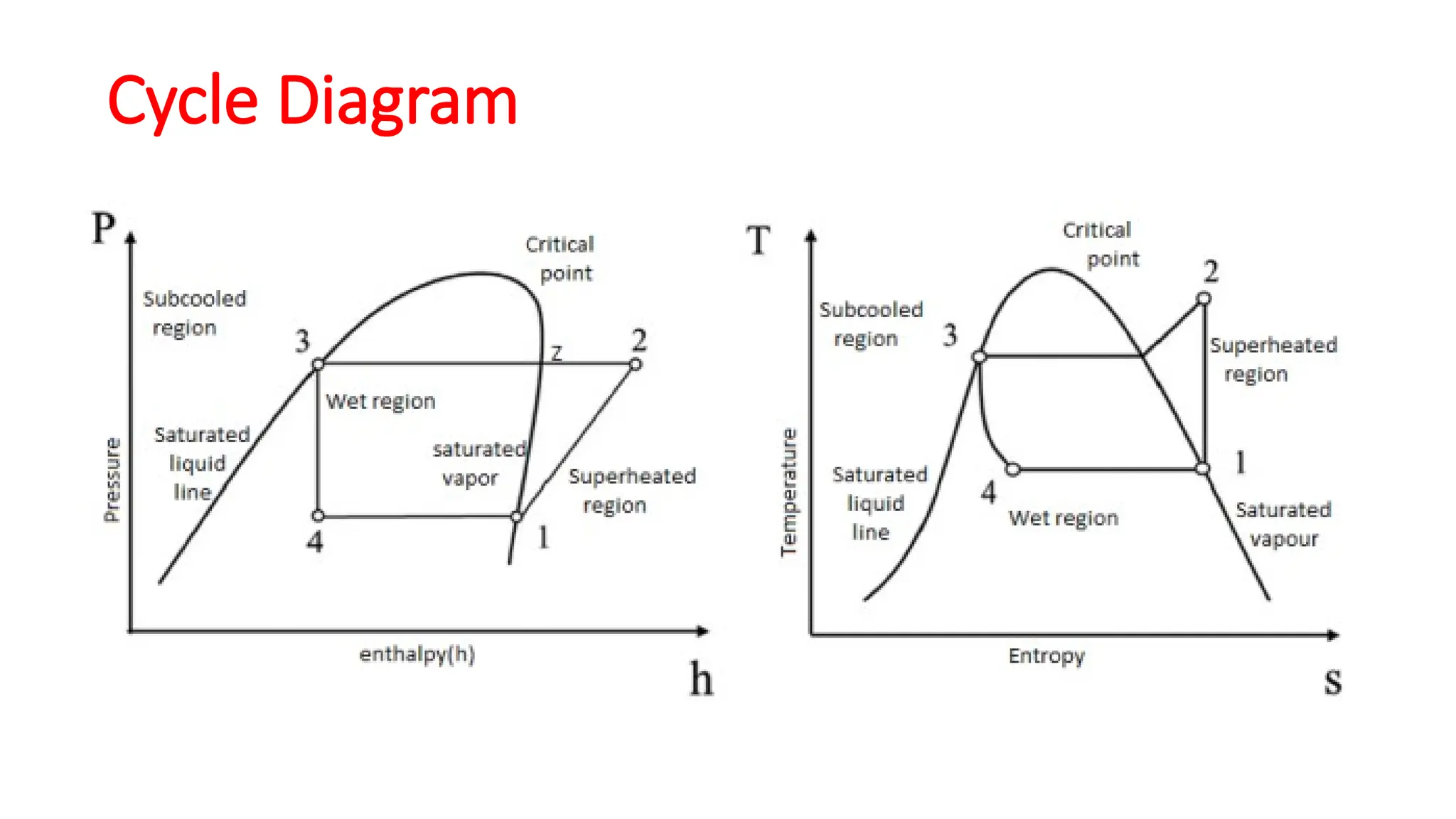

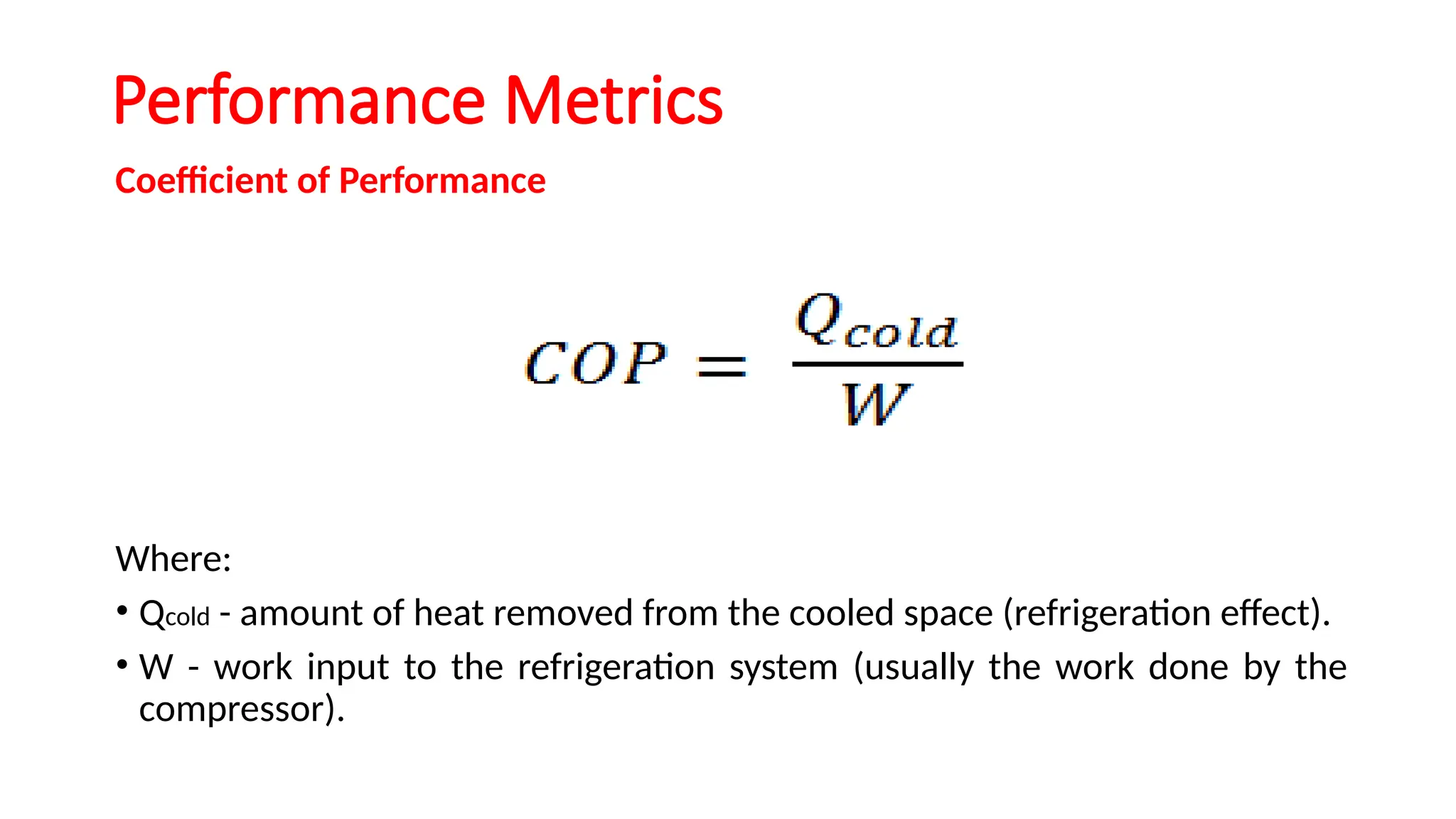

The document outlines the vapour compression refrigeration cycle, detailing the purpose of refrigeration, the principles governing it, and the components involved, such as the compressor, condenser, expansion valve, and evaporator. It explains the cycle's four main processes: compression, condensation, expansion, and evaporation, alongside performance metrics like the coefficient of performance (COP). A higher COP indicates a more efficient system, crucial for energy savings and reduced environmental impact.