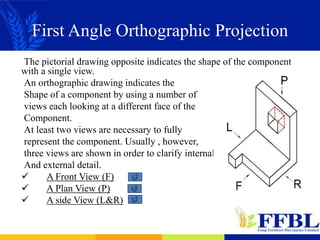

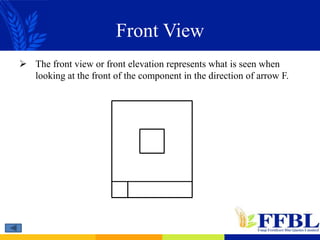

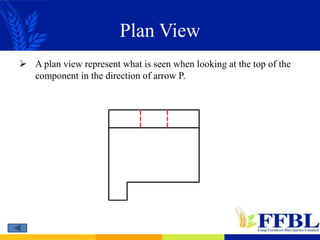

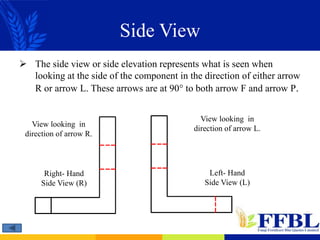

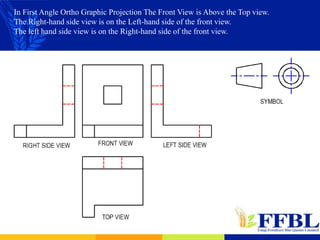

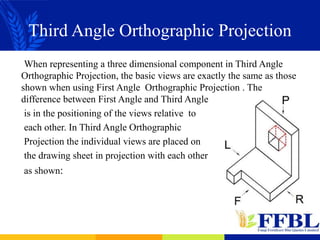

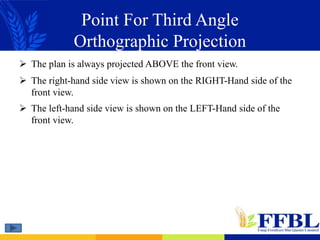

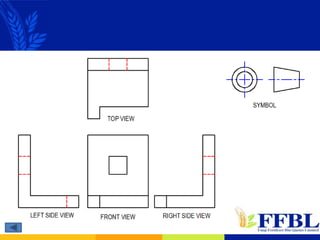

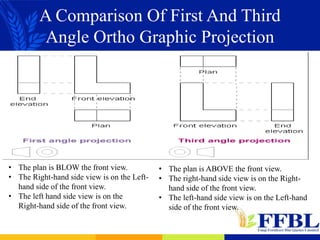

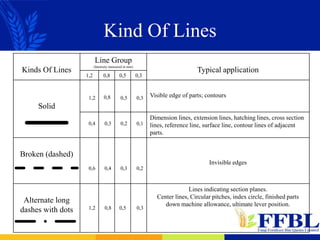

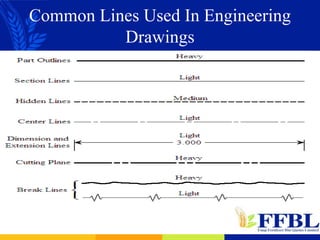

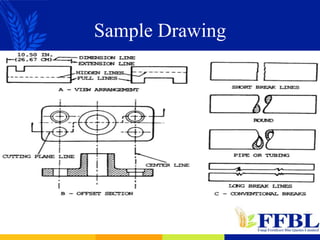

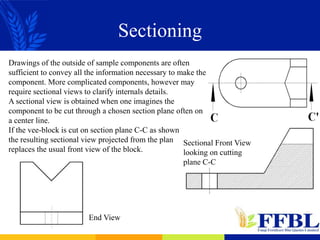

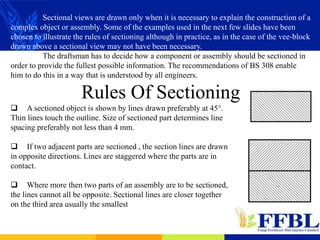

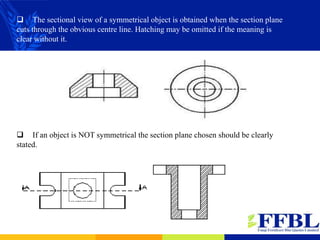

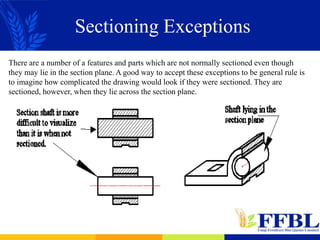

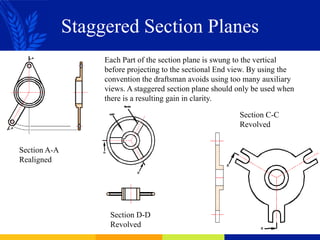

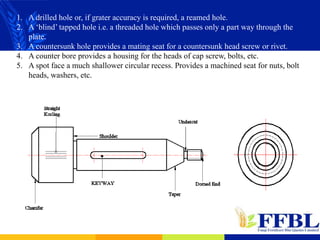

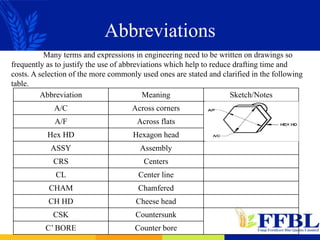

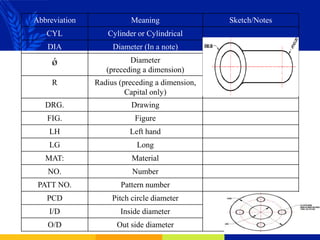

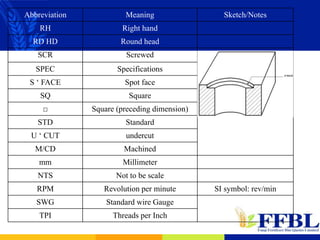

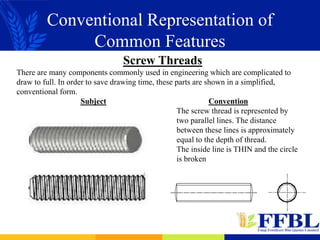

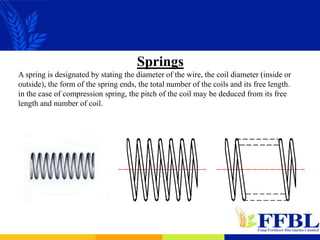

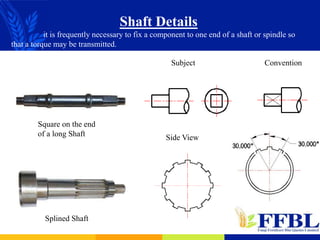

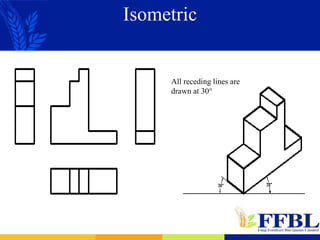

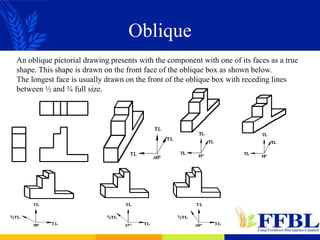

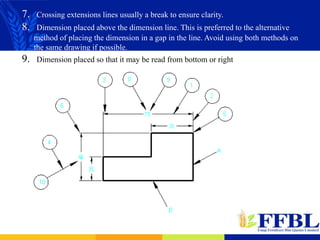

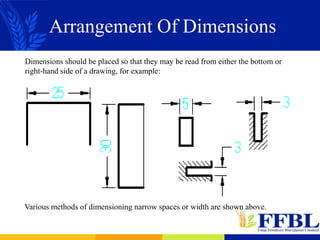

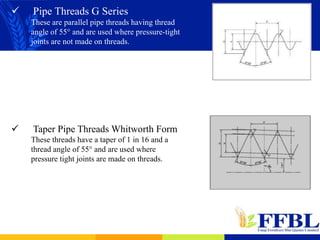

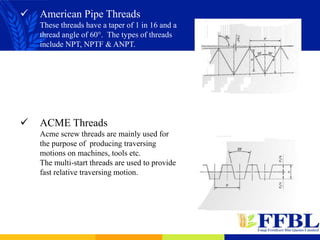

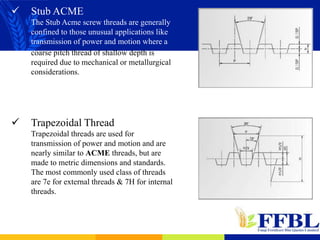

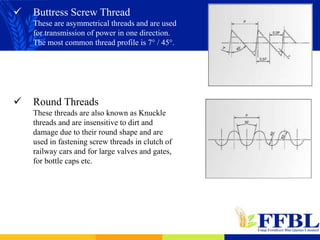

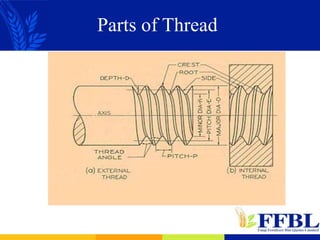

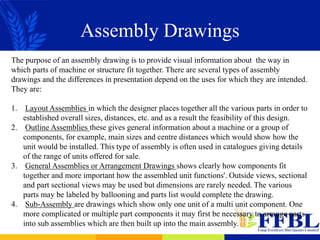

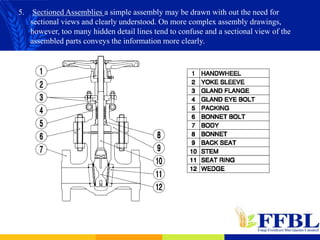

This document provides an overview of basic engineering drawing concepts and standards. It discusses orthographic projection including first and third angle projection. It describes sectioning, lines, abbreviations, dimensioning, and the conventional representation of common features such as threads, springs, and gears. Pictorial drawing methods including isometric and oblique drawings are also covered. The document aims to explain the essential terminology, techniques, and standards used for engineering drawings.