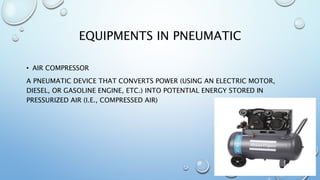

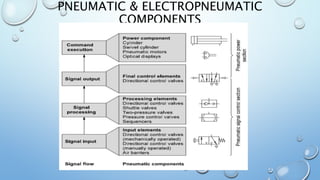

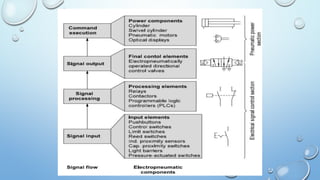

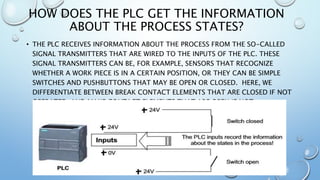

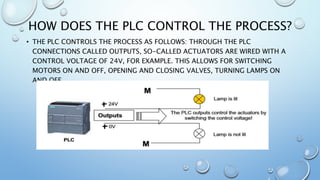

This document provides an overview of basic automation system equipment and components. It describes how automation uses technological devices to perform processes with minimal human interference. Common automation means include mechanical, electrical, electronic, pneumatic and hydraulic systems. Pneumatic equipment can include air compressors, air service units, and pneumatic/electropneumatic components. Hydraulic systems may use levers and cylinders. Programmable logic controllers (PLCs) receive input signals from sensors and switches, process the signals, and output control signals to devices like relays, contactors, lights, and solenoid valves to automate industrial processes.