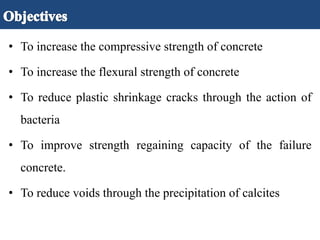

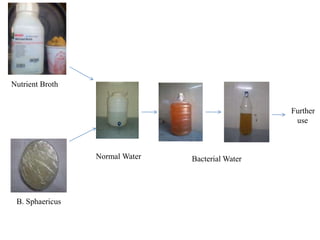

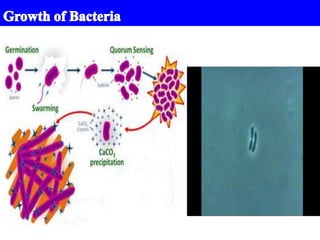

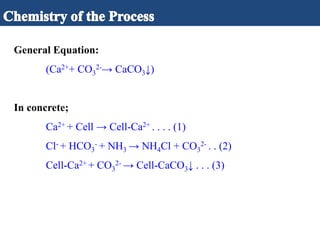

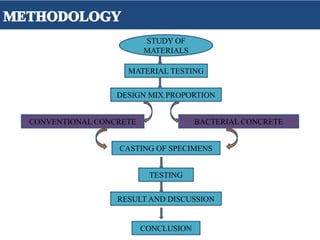

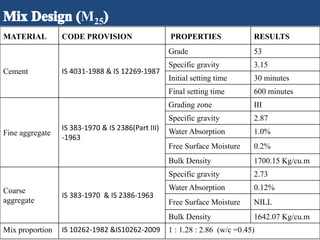

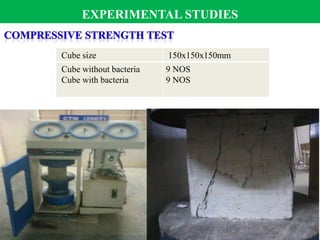

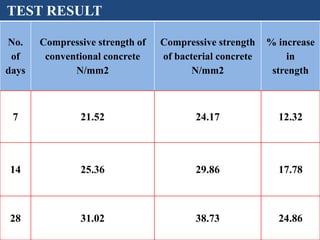

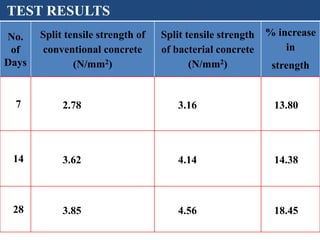

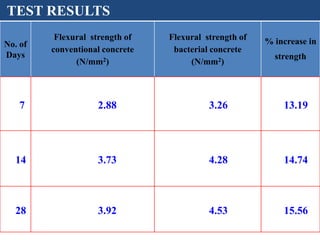

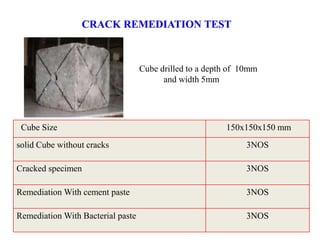

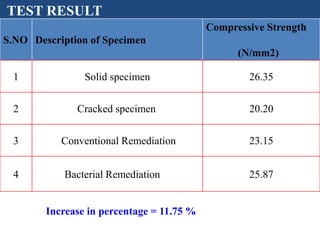

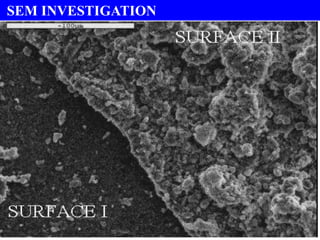

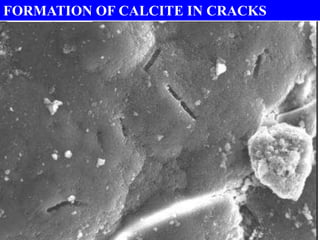

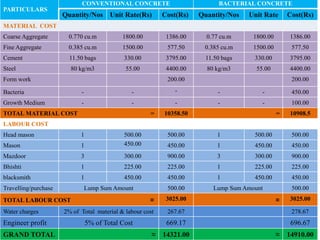

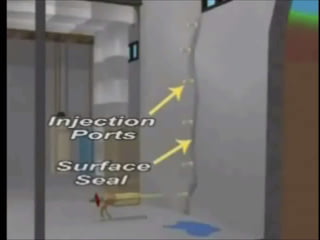

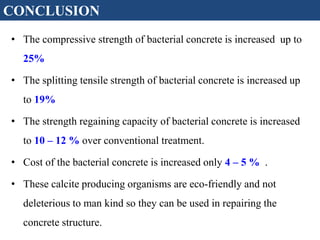

This document discusses the use of bacterial concrete, which uses microbiologically-induced calcium carbonate precipitation to improve the properties of concrete. Various bacteria like Bacillus pasteurii and Bacillus sphaericus are able to continuously precipitate calcium carbonate. Bacterial concrete has been shown to increase the compressive, tensile, and flexural strength of concrete by up to 25% compared to conventional concrete. It can also help reduce cracks and improve the strength regeneration of cracked concrete. The cost of bacterial concrete is only 4-5% higher than conventional concrete. Scanning electron microscope images provide evidence of calcite precipitation in cracks by the bacteria.