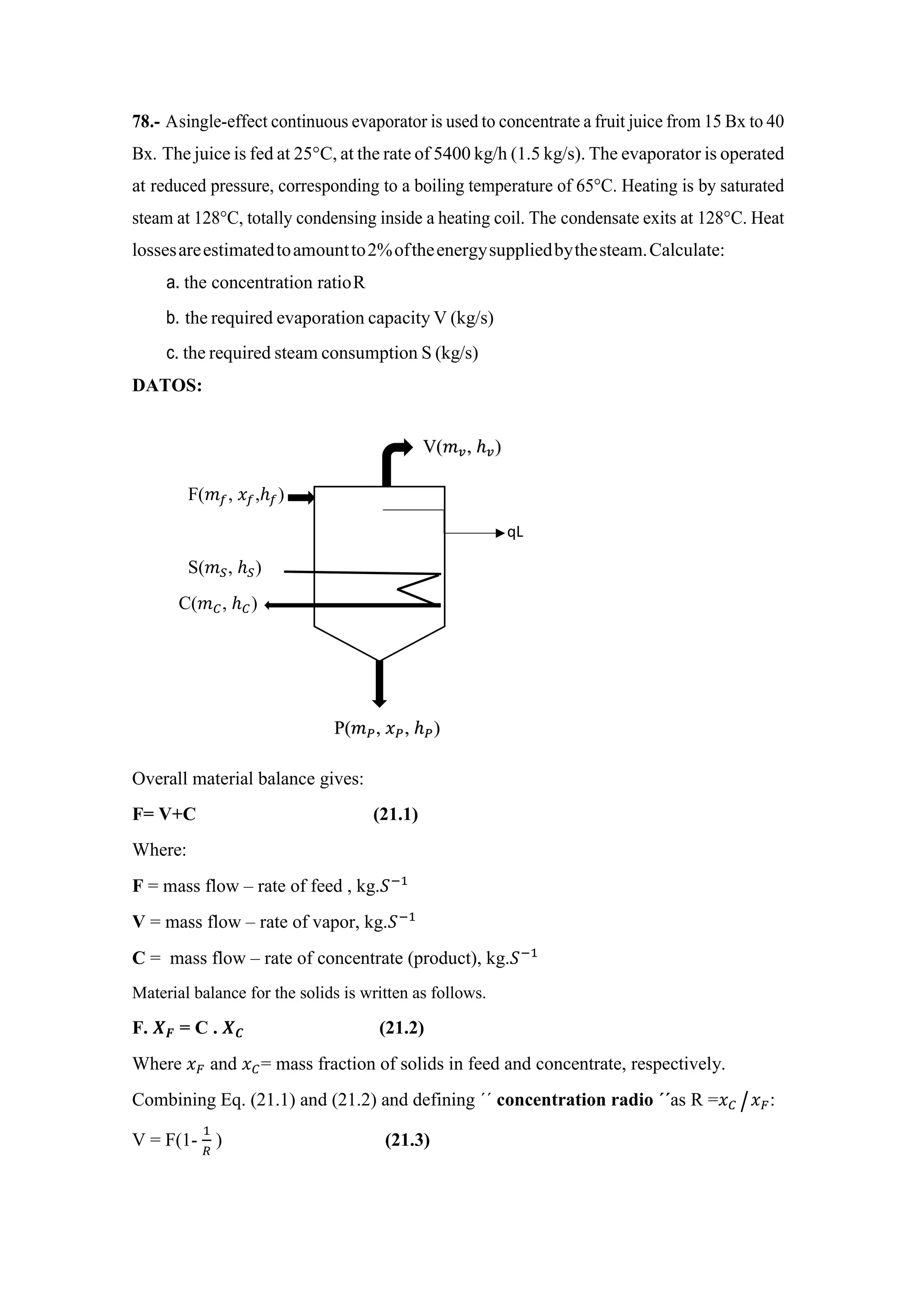

This document provides information to calculate the amount of sodium sulfite needed to remove oxygen from water in a boiler system. It states that sodium sulfite reacts with oxygen to remove it from water according to the given chemical reaction. It then provides the amount of water, its oxygen content, and asks to calculate the theoretical amount of sodium sulfite needed to remove the oxygen while maintaining a 35% excess of sodium sulfite.