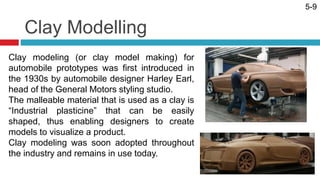

The automotive design process involves several key steps: establishing a design brief, generating concepts, selecting themes, clay modeling, class A surfacing, design evaluation, prototype development and testing, and product launch. Designers create thousands of sketches inspired by the brief and their design thoughts. Themes are selected that meet the design intent, look great, and match the brief. Clay modeling and class A surfacing using computer-aided tools help visualize the product. Prototypes are built and tested before a vehicle is unveiled at an auto show and manufacturing begins.