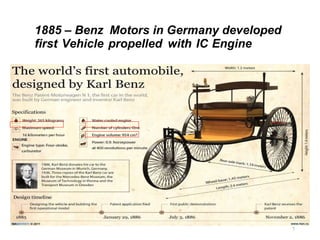

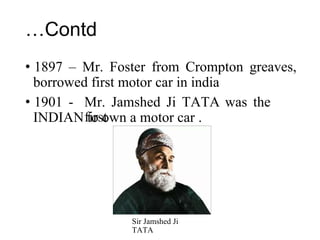

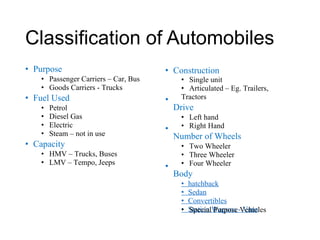

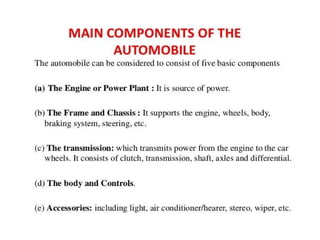

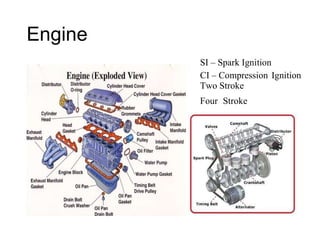

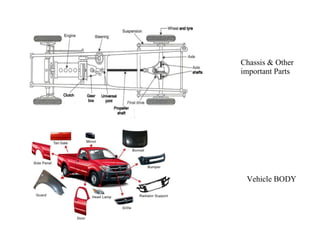

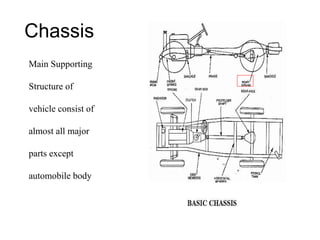

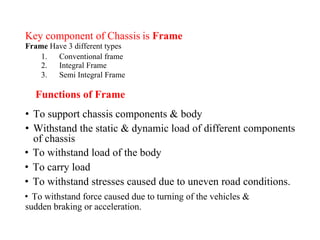

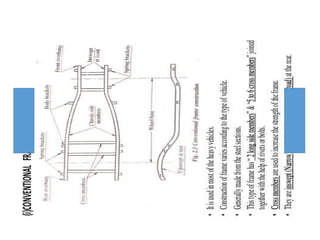

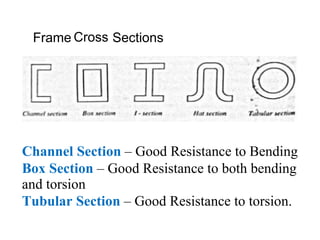

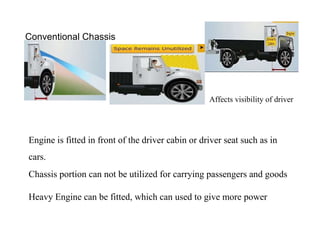

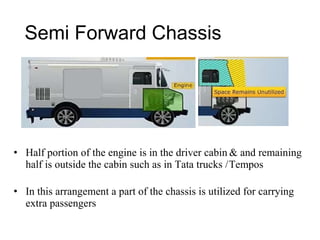

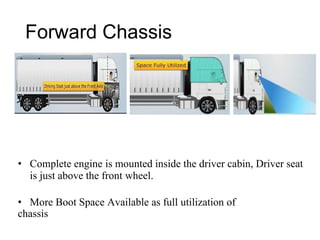

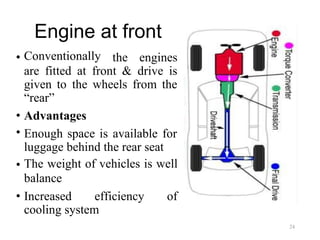

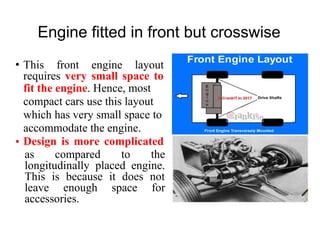

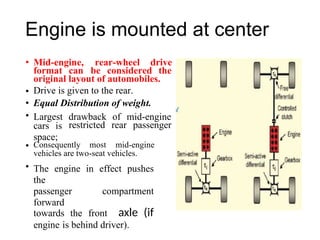

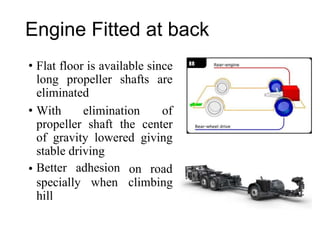

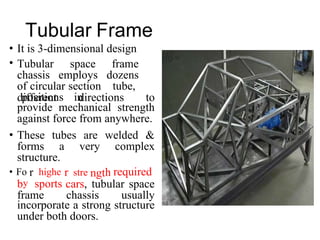

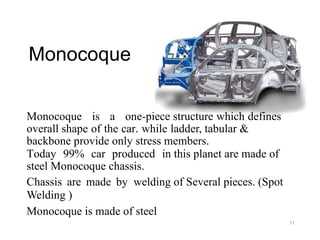

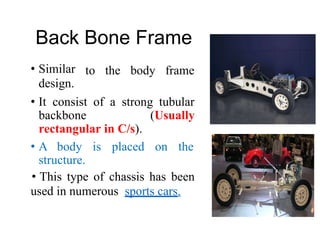

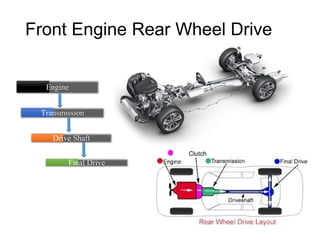

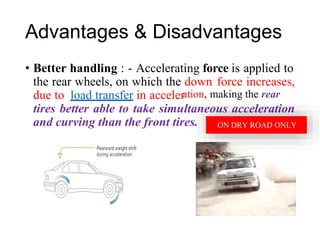

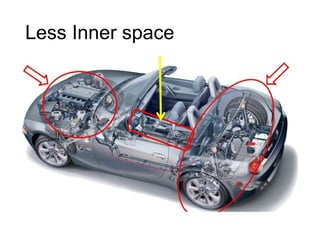

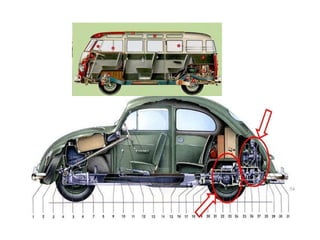

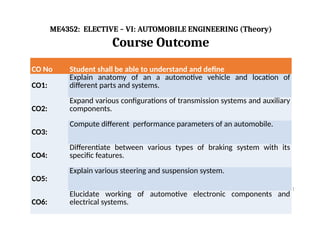

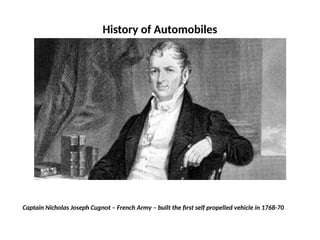

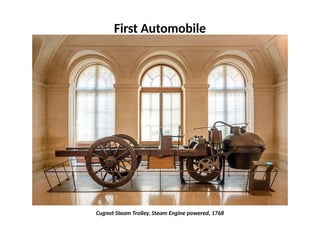

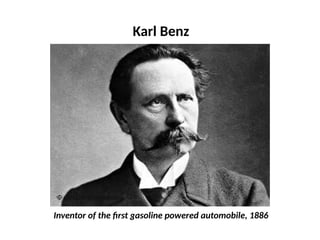

The document outlines the vision, mission, and educational objectives of the mechanical department focusing on automobile engineering. It discusses the definition of automobiles, their historical development, various types of vehicle layouts, and chassis classifications. Key components, advantages, and disadvantages of different chassis types and their engineering considerations are also addressed.

![e is e

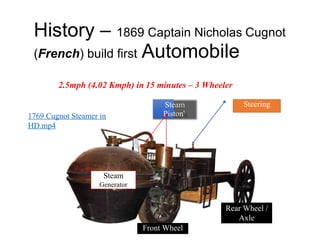

1801 – Richard

Carriage

threvithrick – Firs Steam

TREVITHICK'S PUFFING DEVIL

ON TREVITHICK DAY 2017.mp4

Trevithick was born in 1771 in a

mining

England.

village

He

in

was

Cornwall,

terrible

a

student–his teachers thought he

was a “disobedient, slow,

obstinate, [and] spoiled boy” who

anything,

basically

would never amount to

and in fact he was

illiterat

to tinker

h entir life–but he loved

with tools and machines6.

Puffing DEVIL

Wheels

Steam

Generator

Chimney](https://image.slidesharecdn.com/unit1-240812112125-14a62404/85/Automobile-Engineering-Elective-subject-1-13-320.jpg)