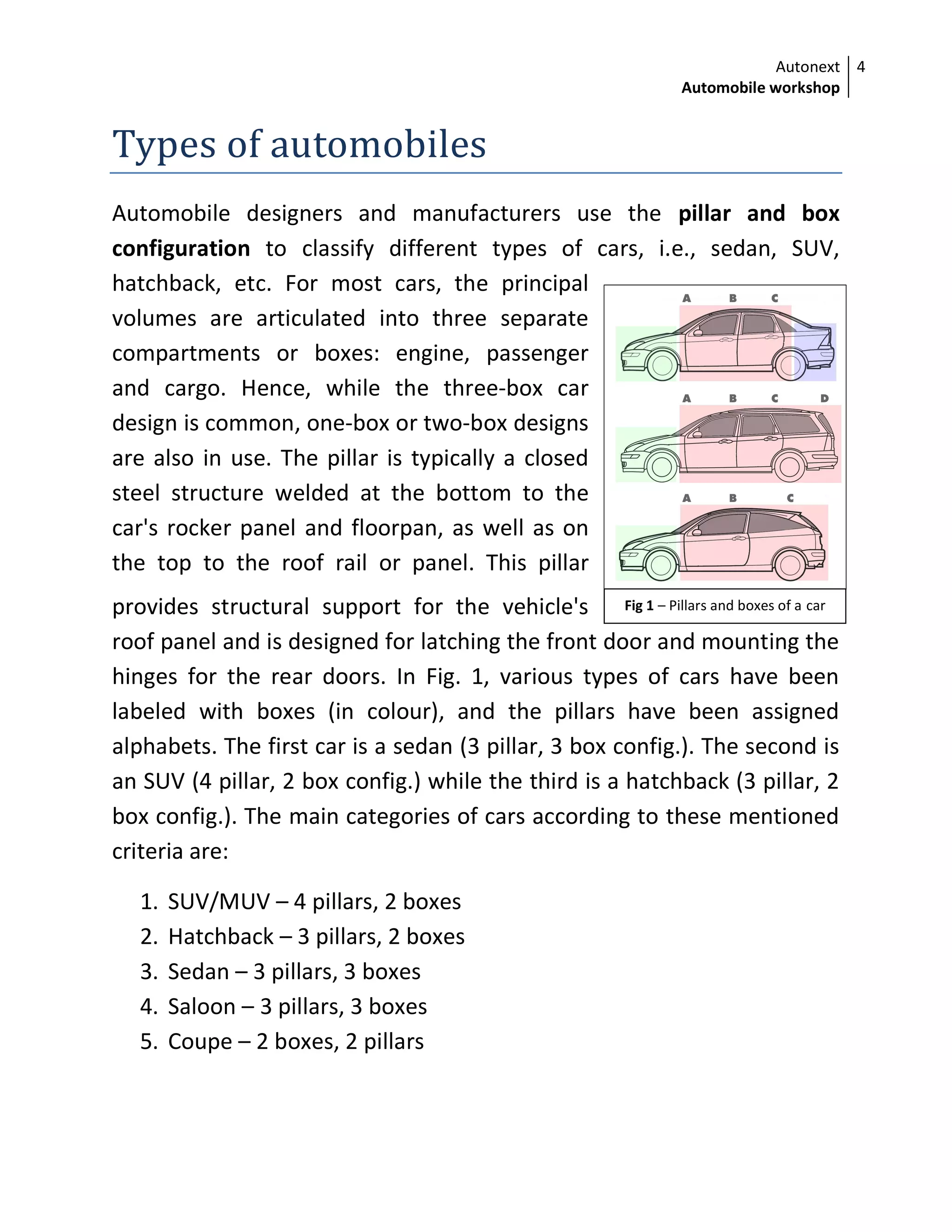

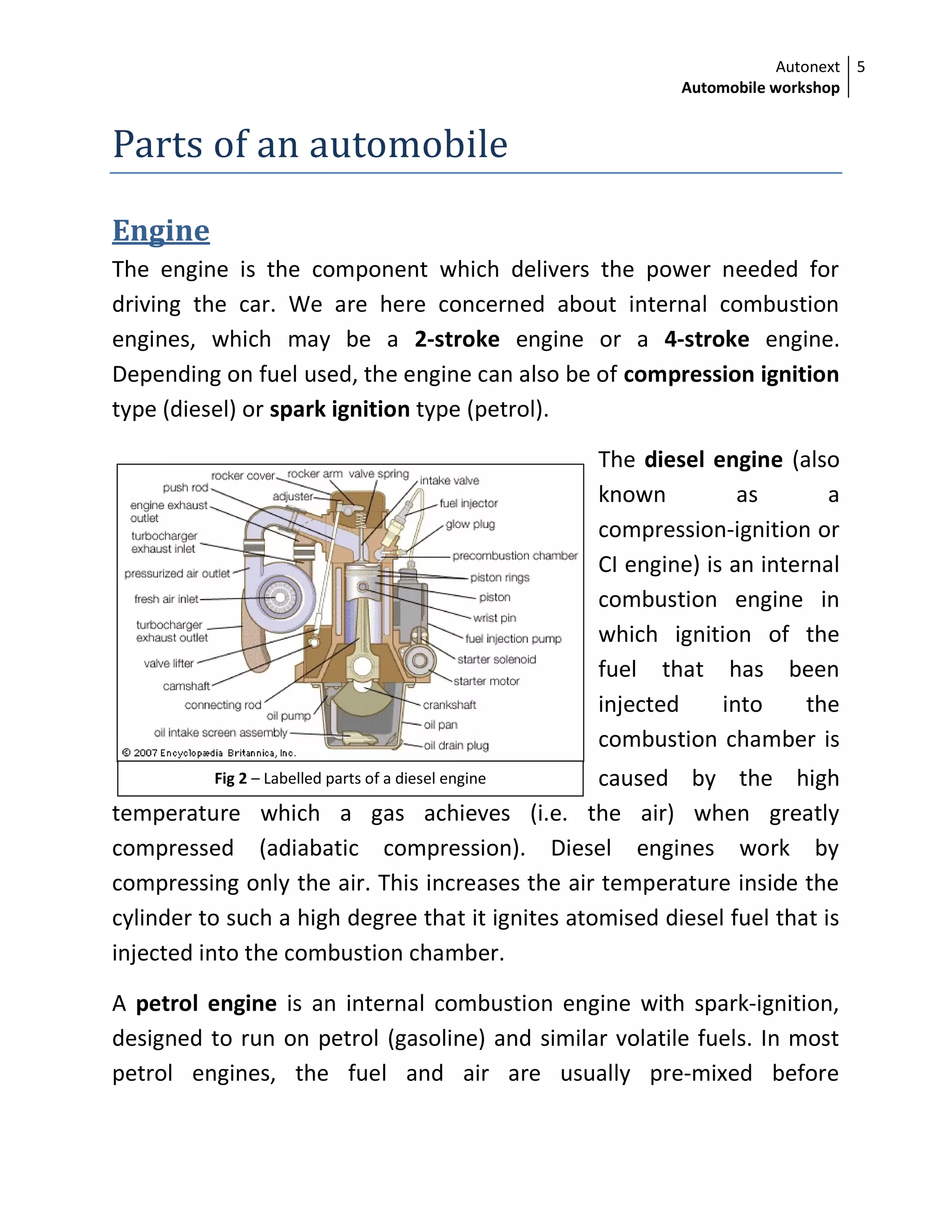

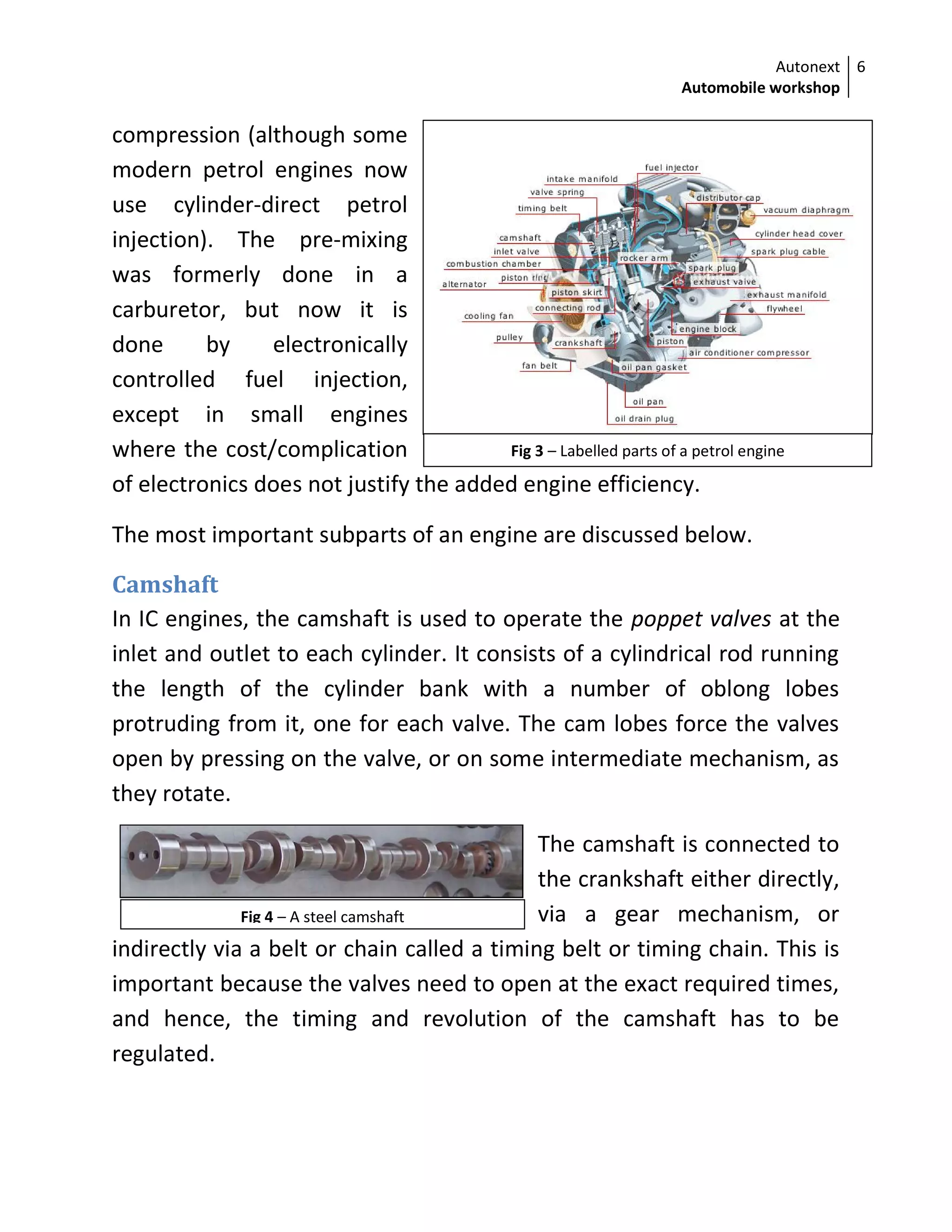

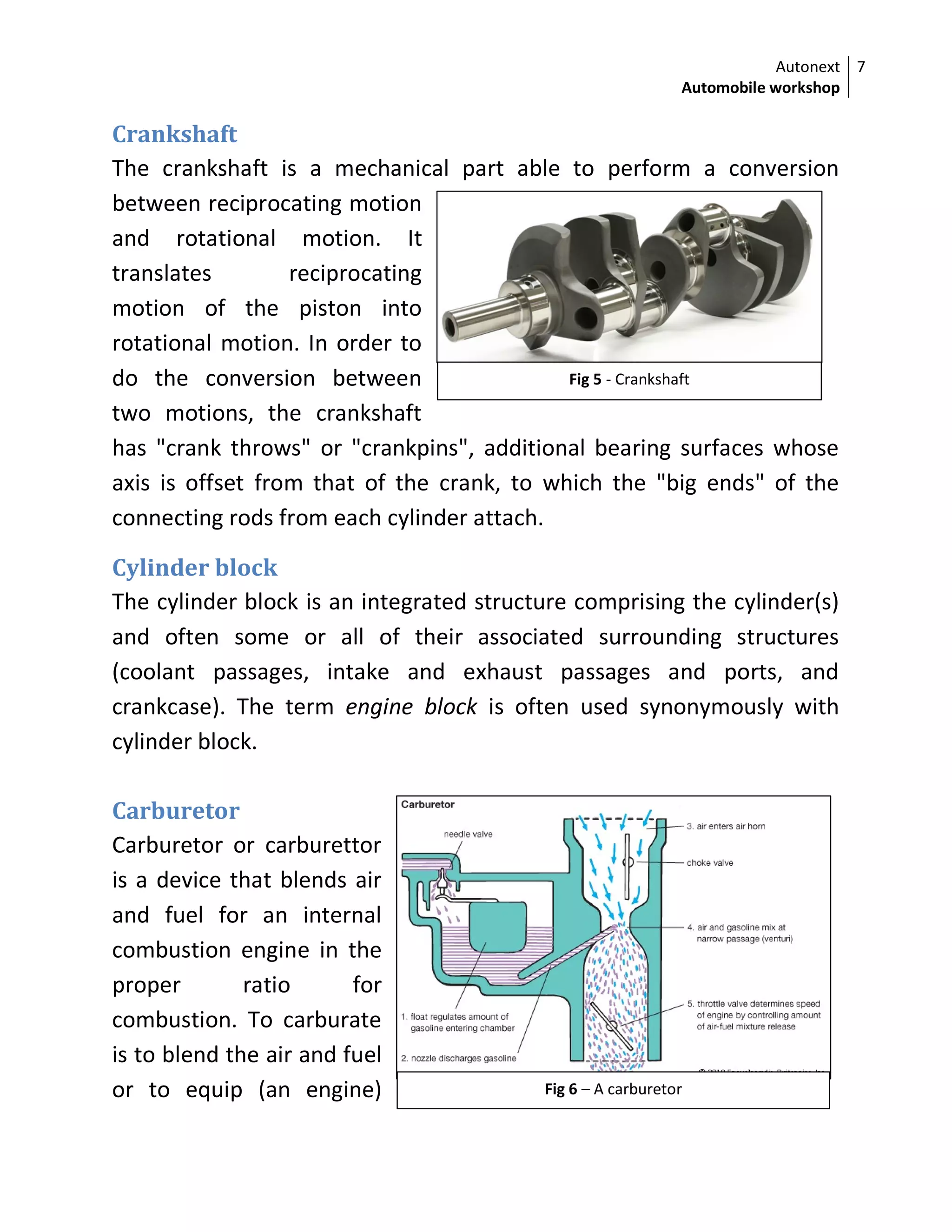

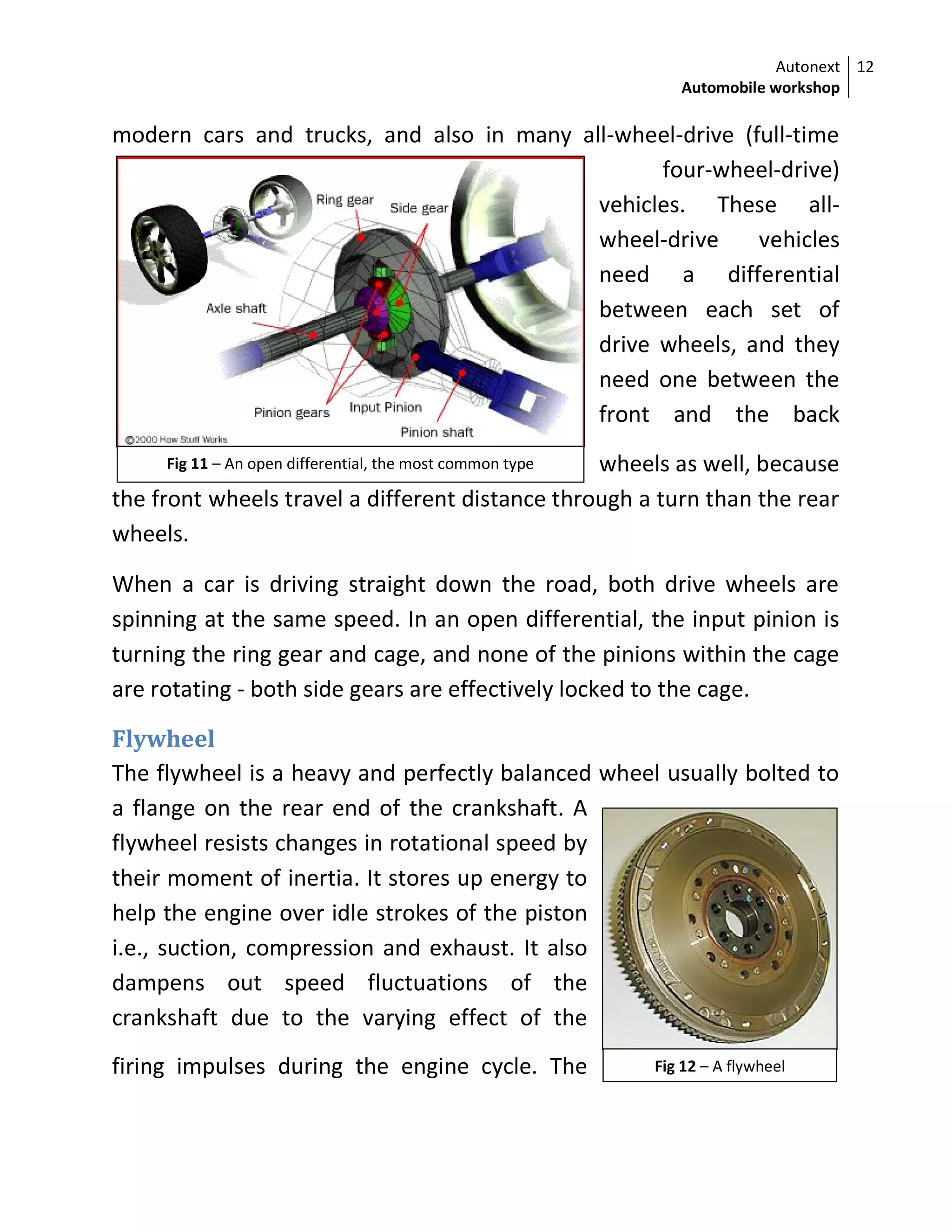

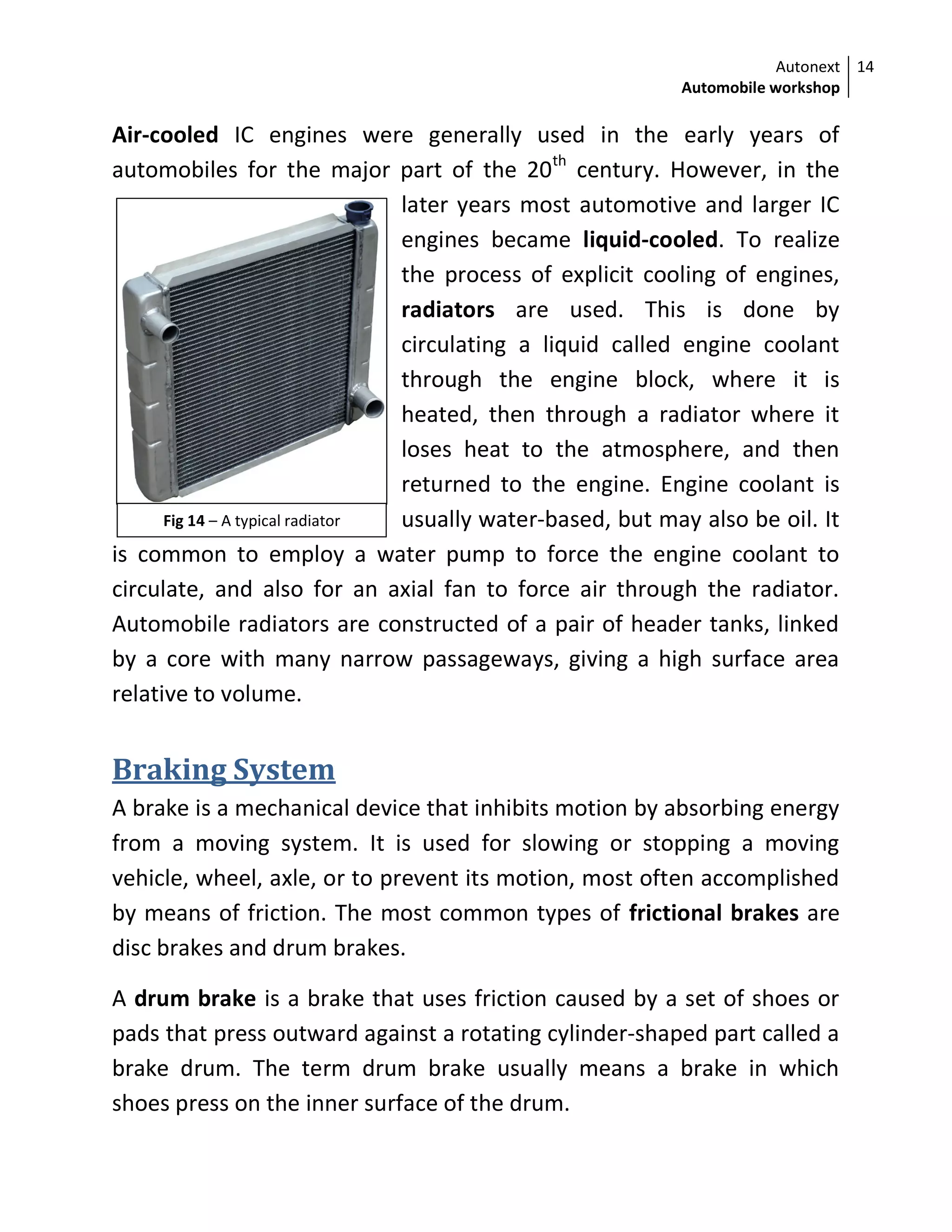

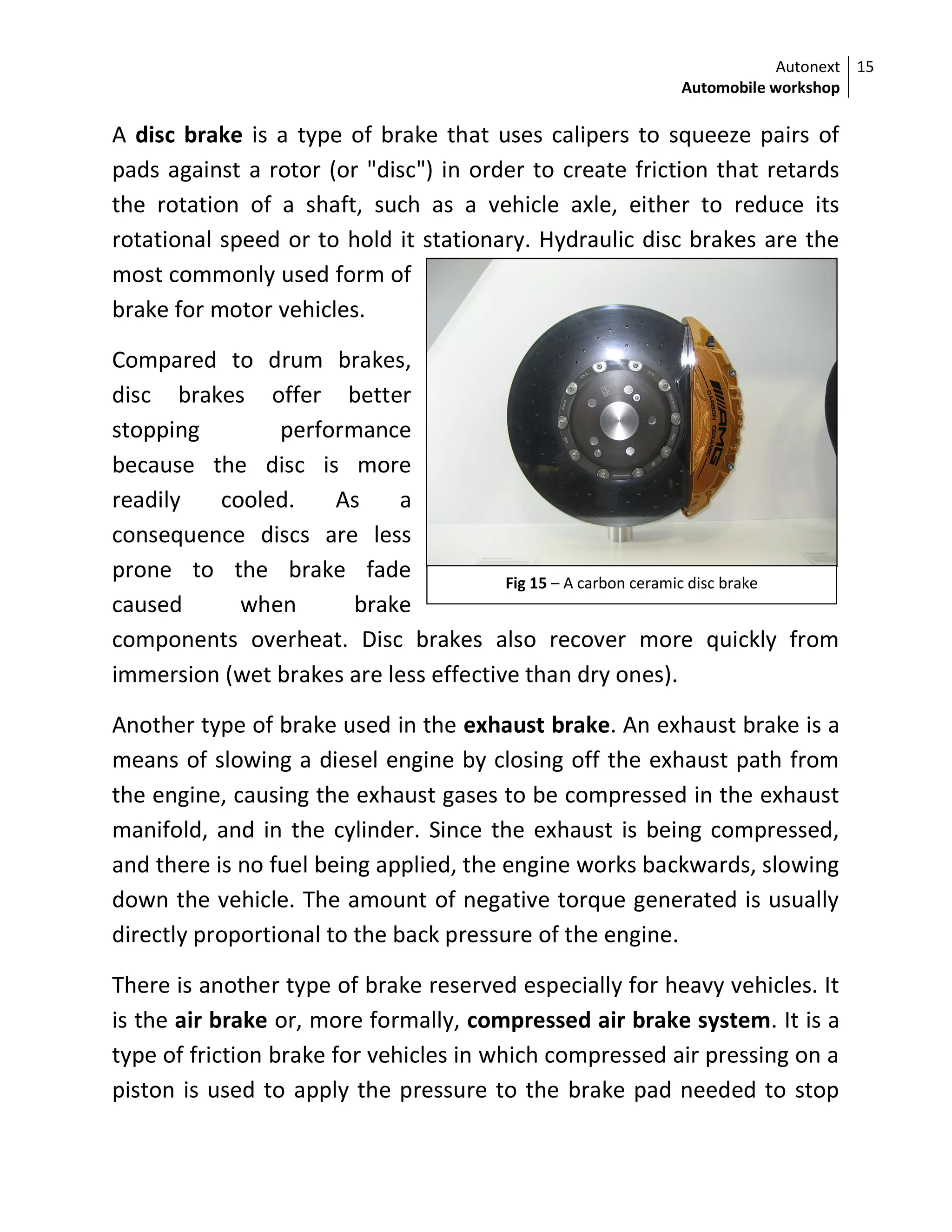

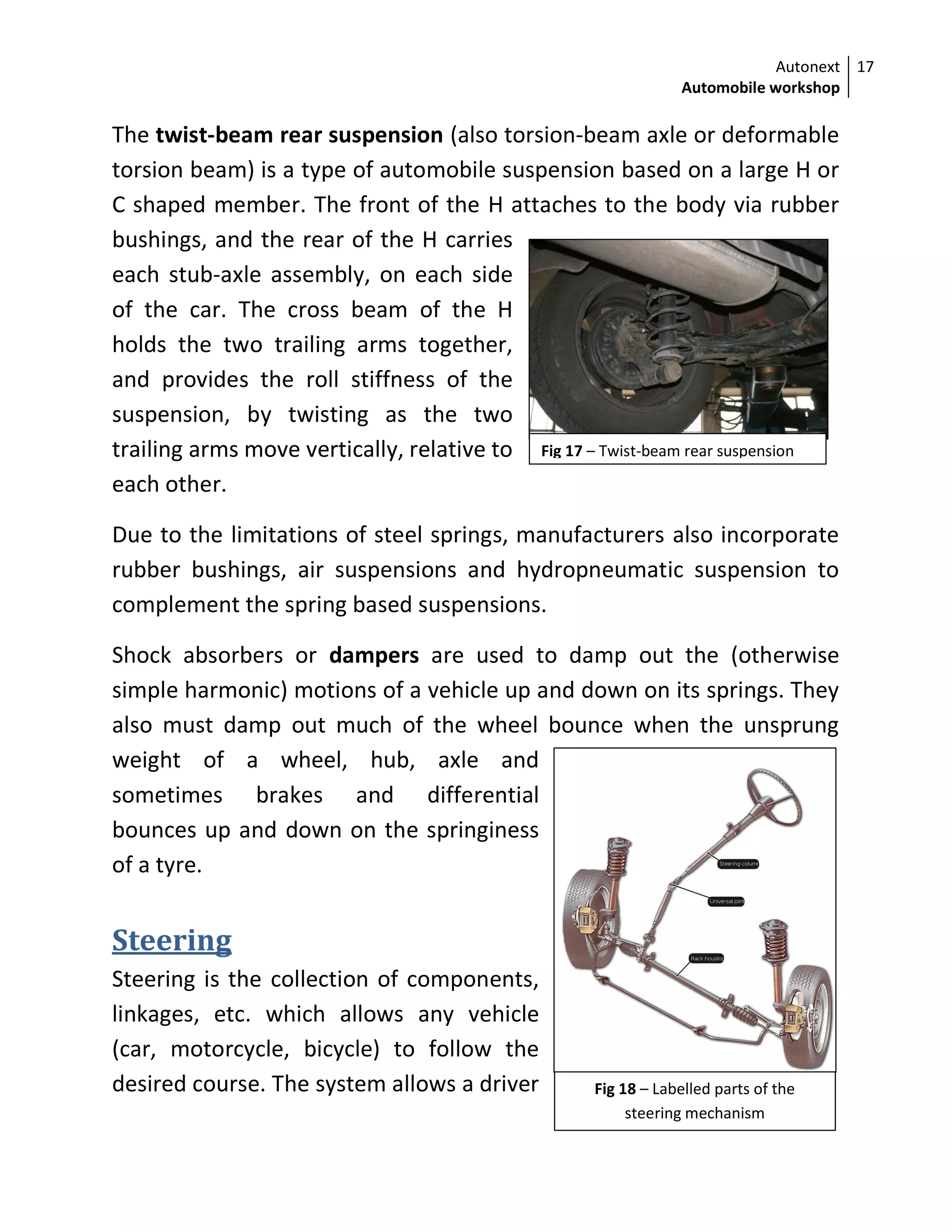

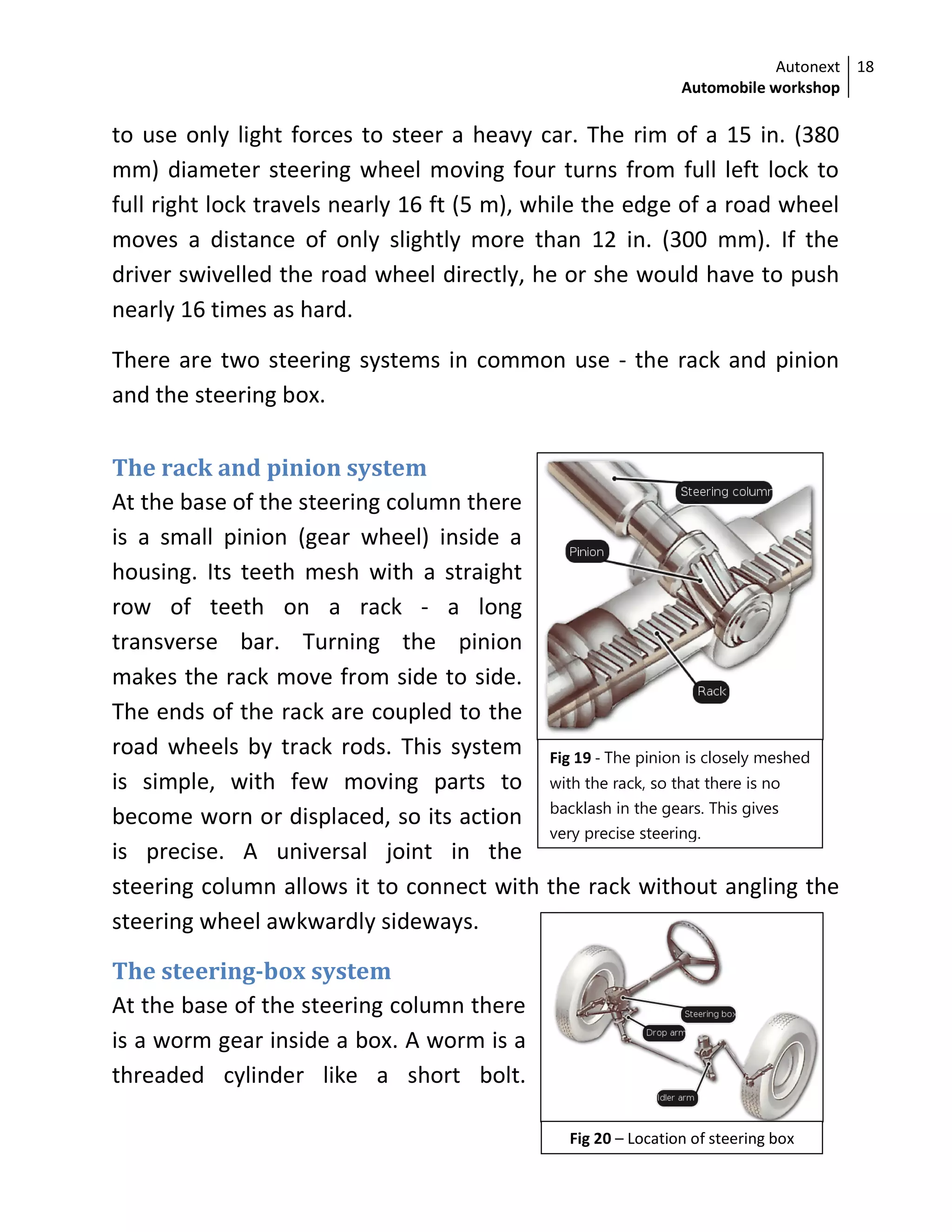

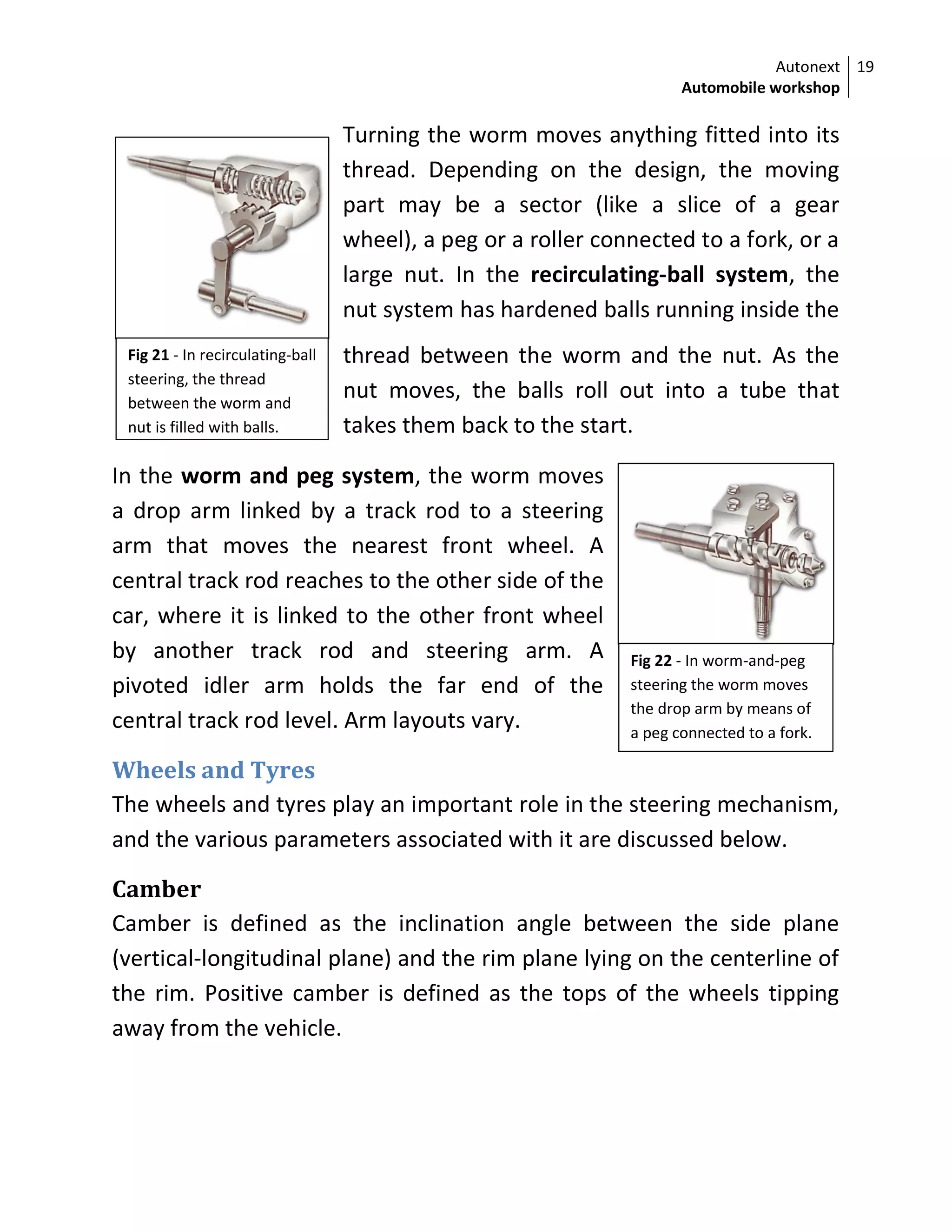

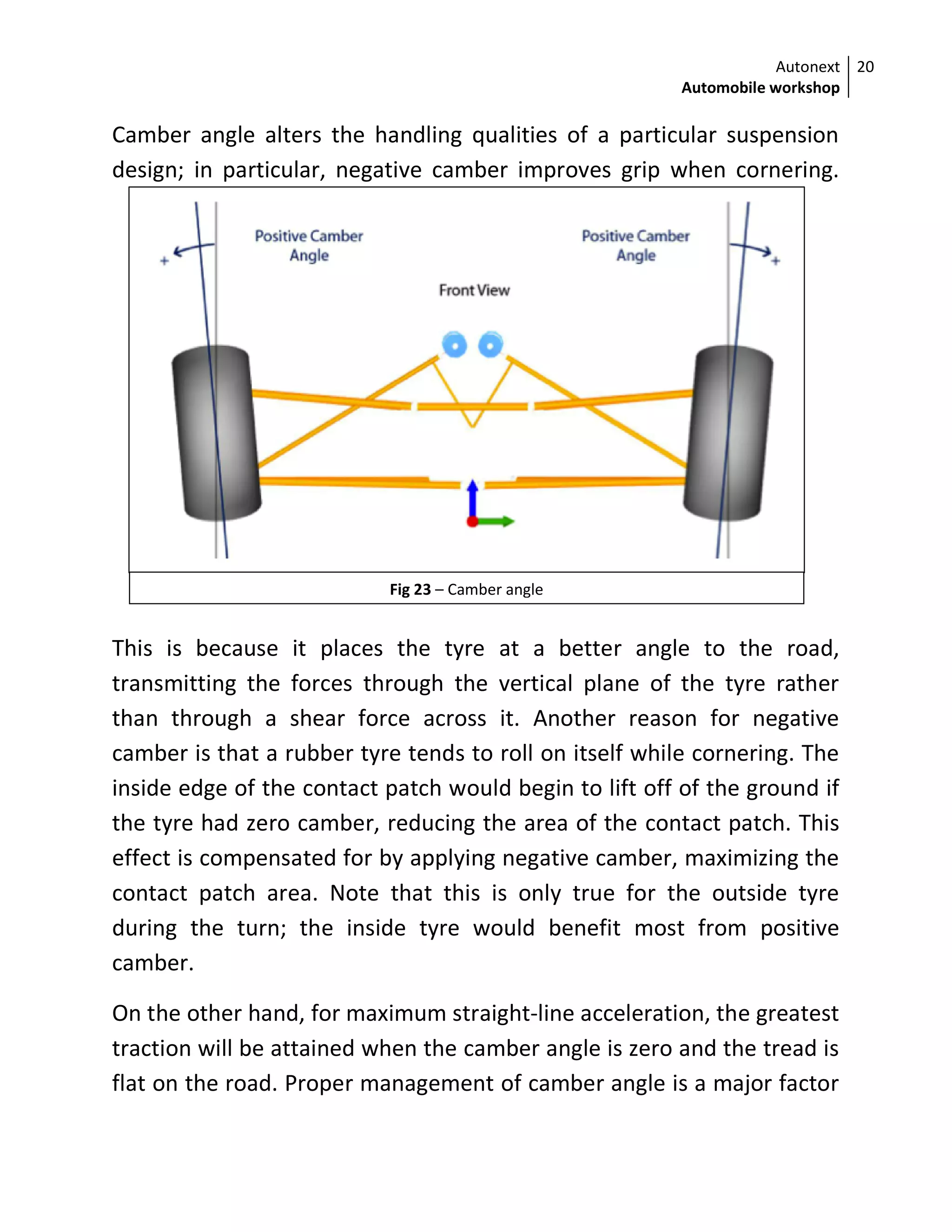

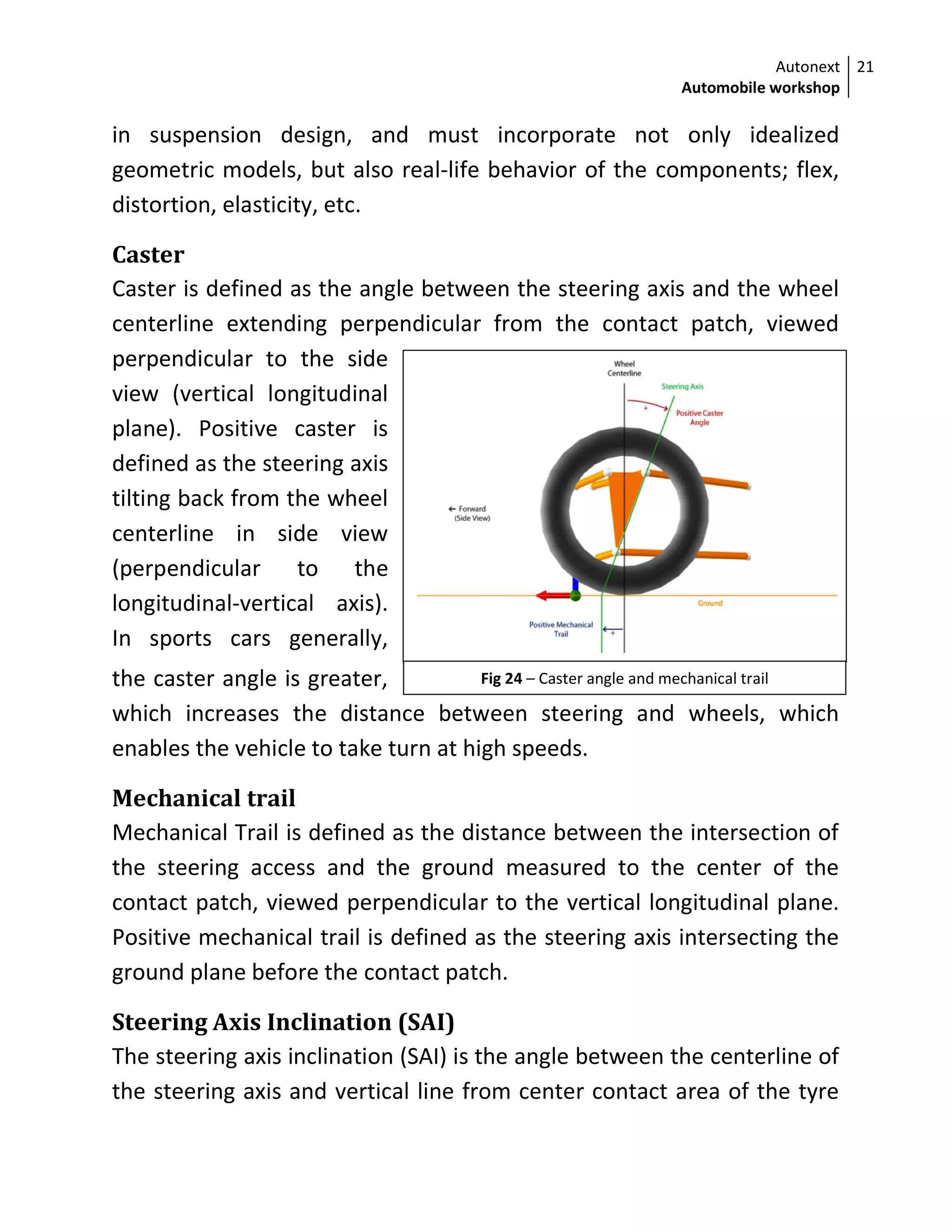

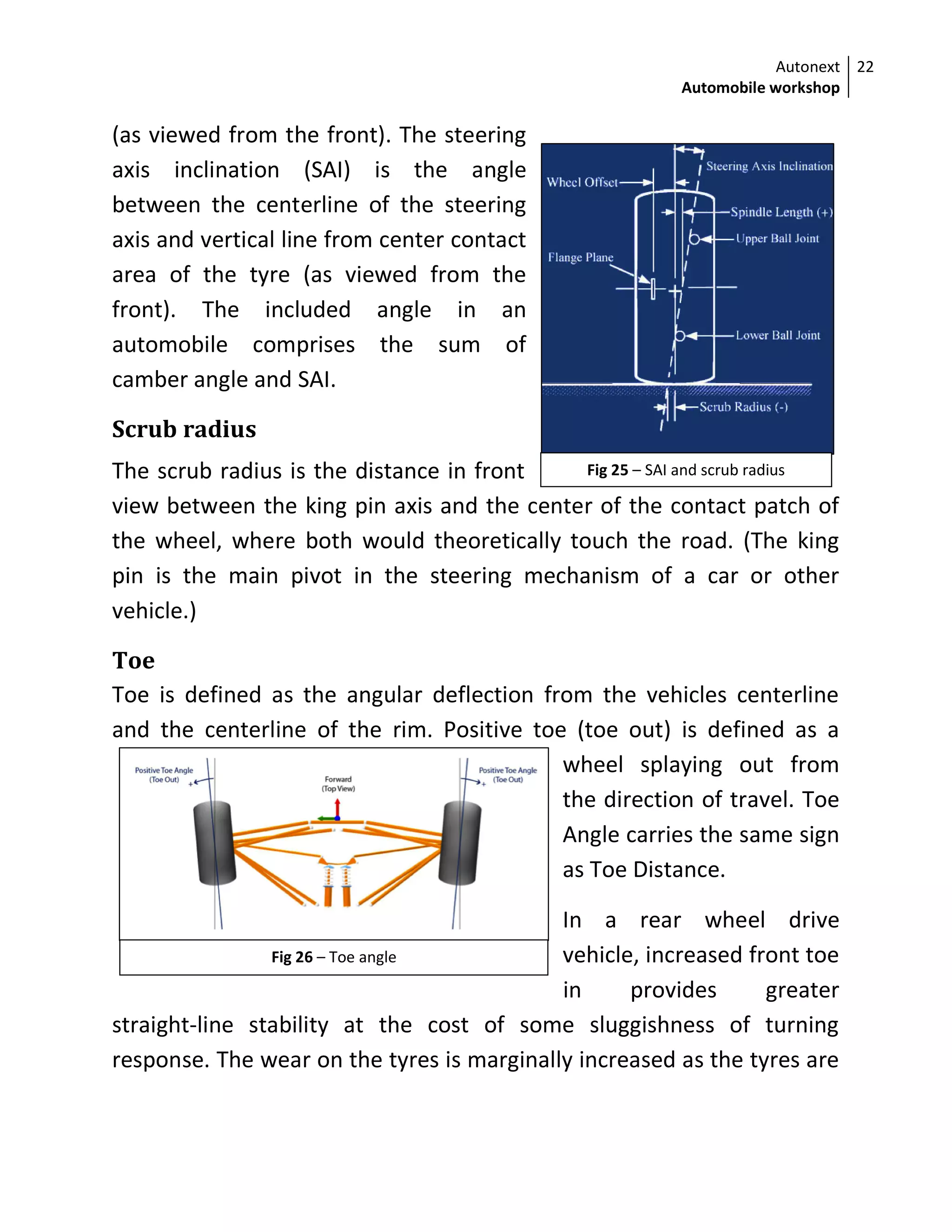

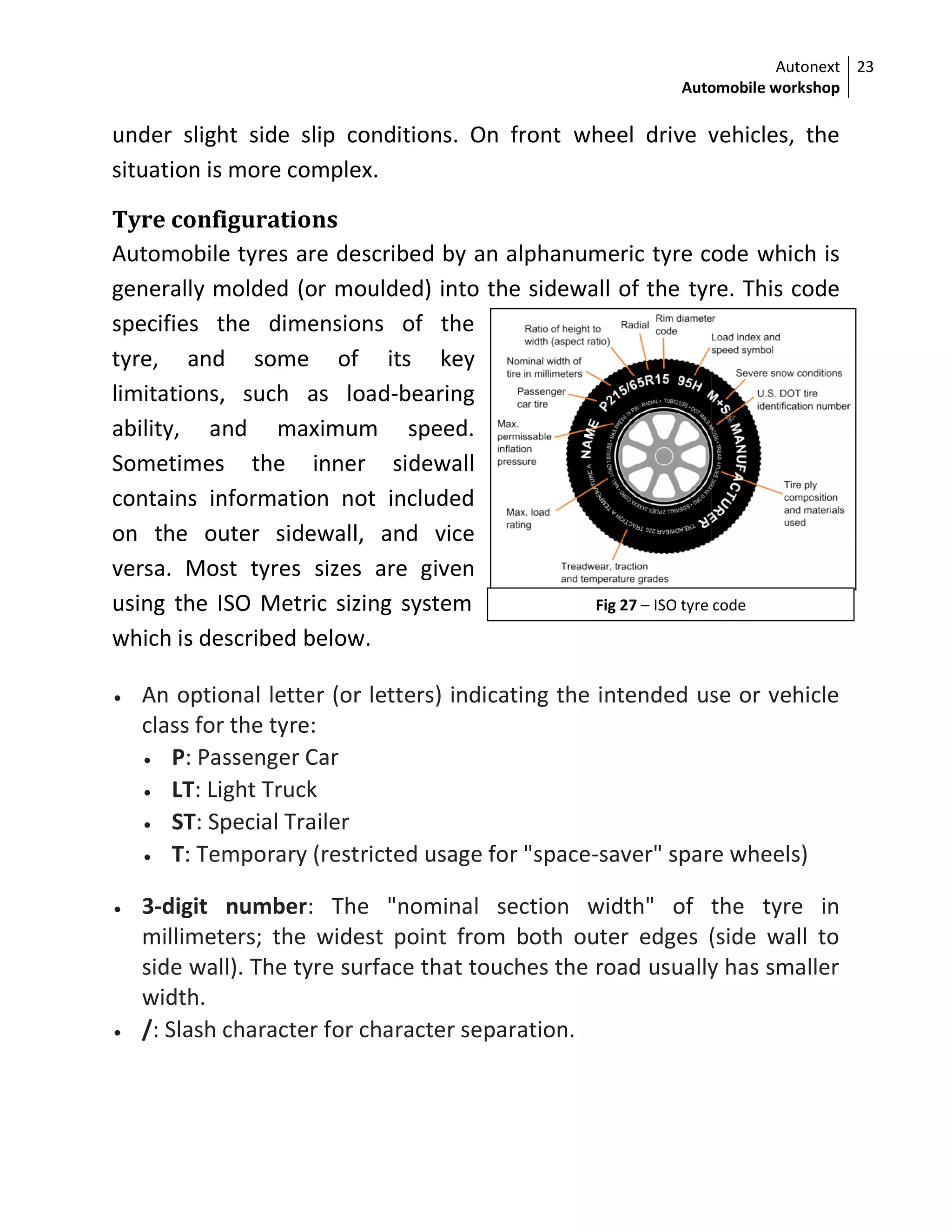

The document is a report on an automobile workshop titled 'Automobile Basics & Advanced System' organized by Autonext in Jamshedpur, attended by a mechanical engineering student. It covers various automobile types, parts, and advanced technologies, detailing components such as the engine, transmission system, and braking mechanisms. The report serves as an introduction to the technical aspects of automobiles without delving into their historical evolution.