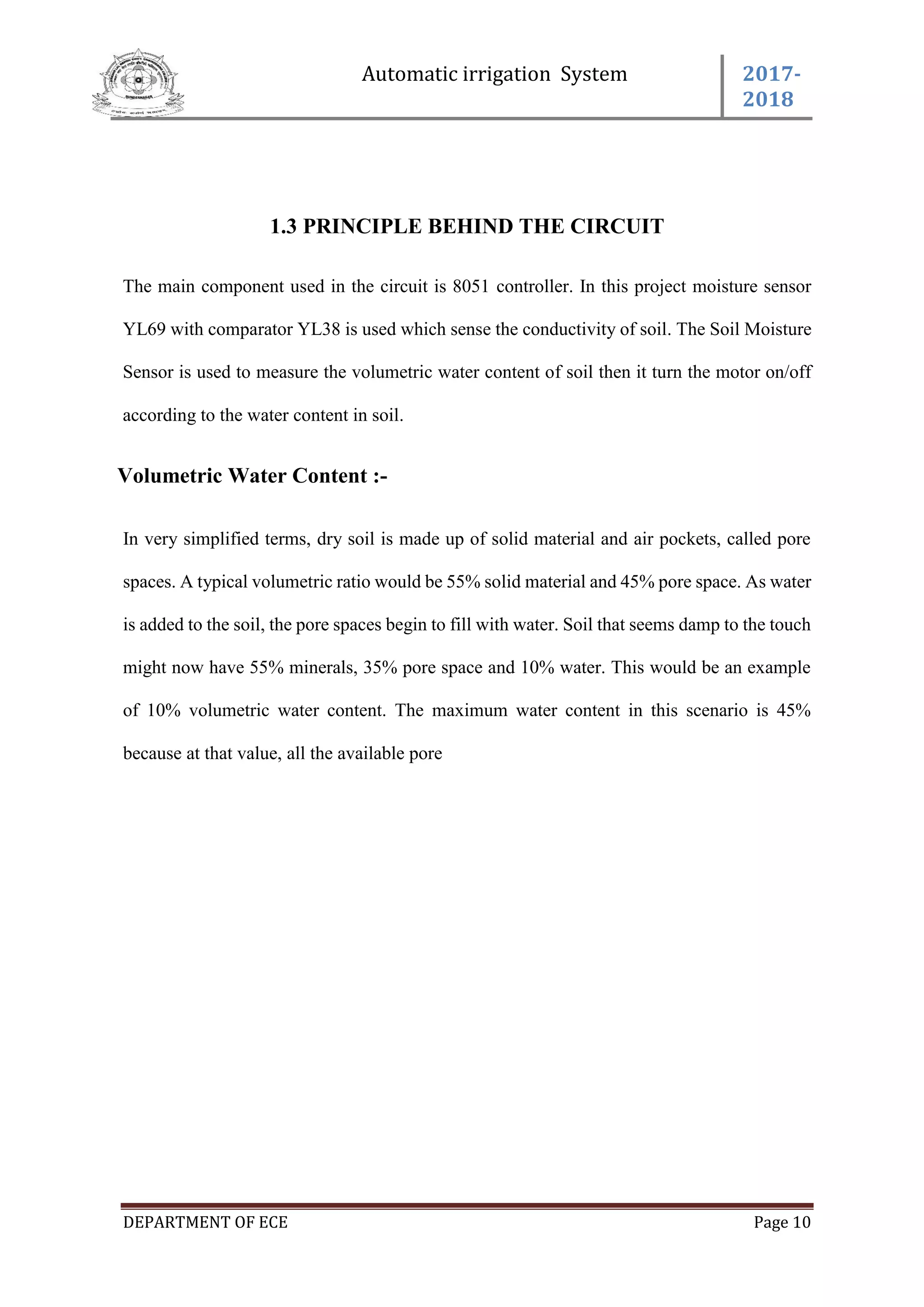

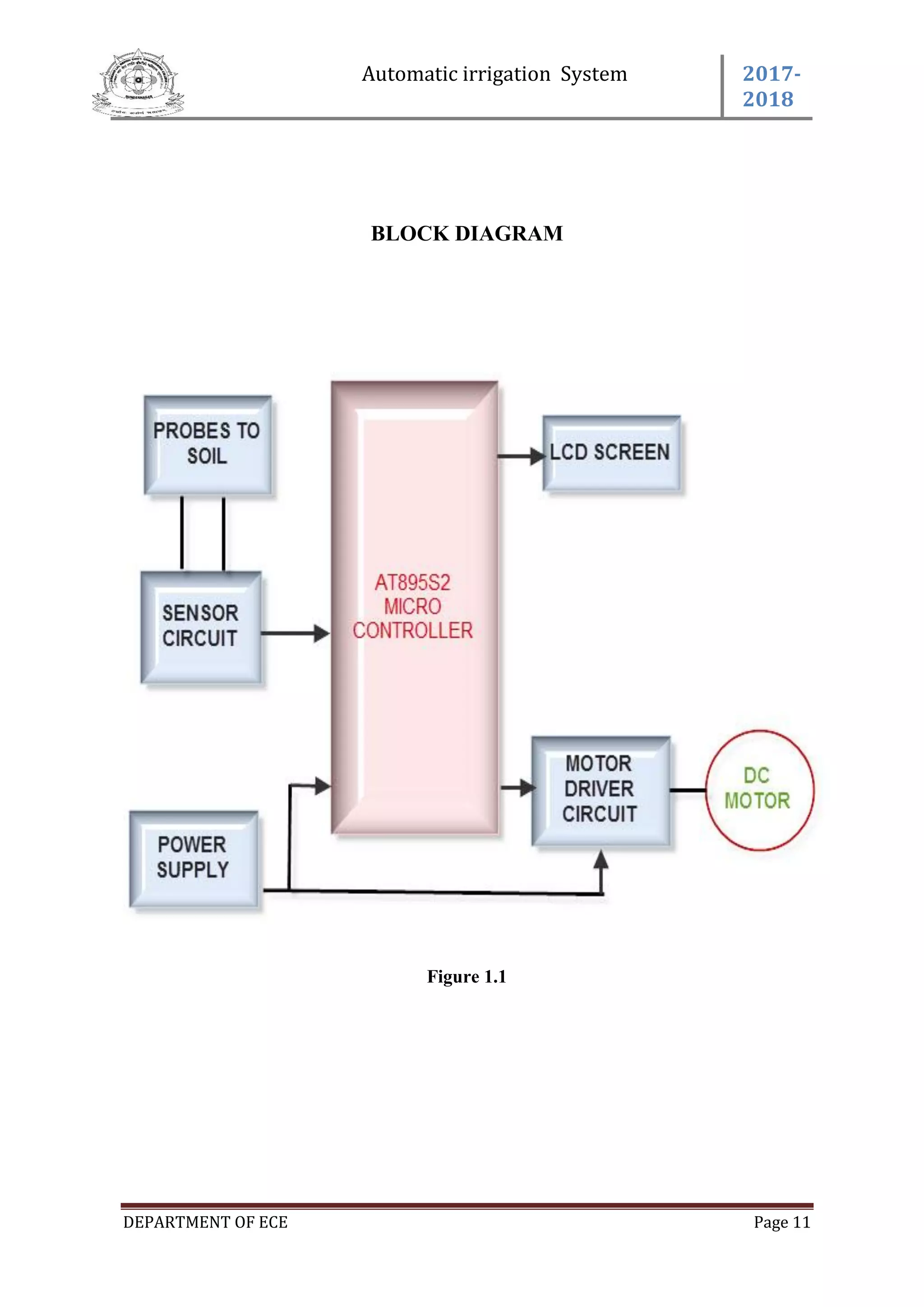

This document provides details about an automatic irrigation system project completed by four students for their Bachelor of Technology degree. It includes an introduction describing the motivation and objectives of the project, as well as chapters covering the hardware and software components of the system. The system uses a microcontroller, soil moisture sensor, LCD display, and other components to automate irrigation by turning a water pump on and off based on soil moisture levels, saving water and farmer time.

![Automatic irrigation System 2017-

2018

DEPARTMENT OF ECE Page 47

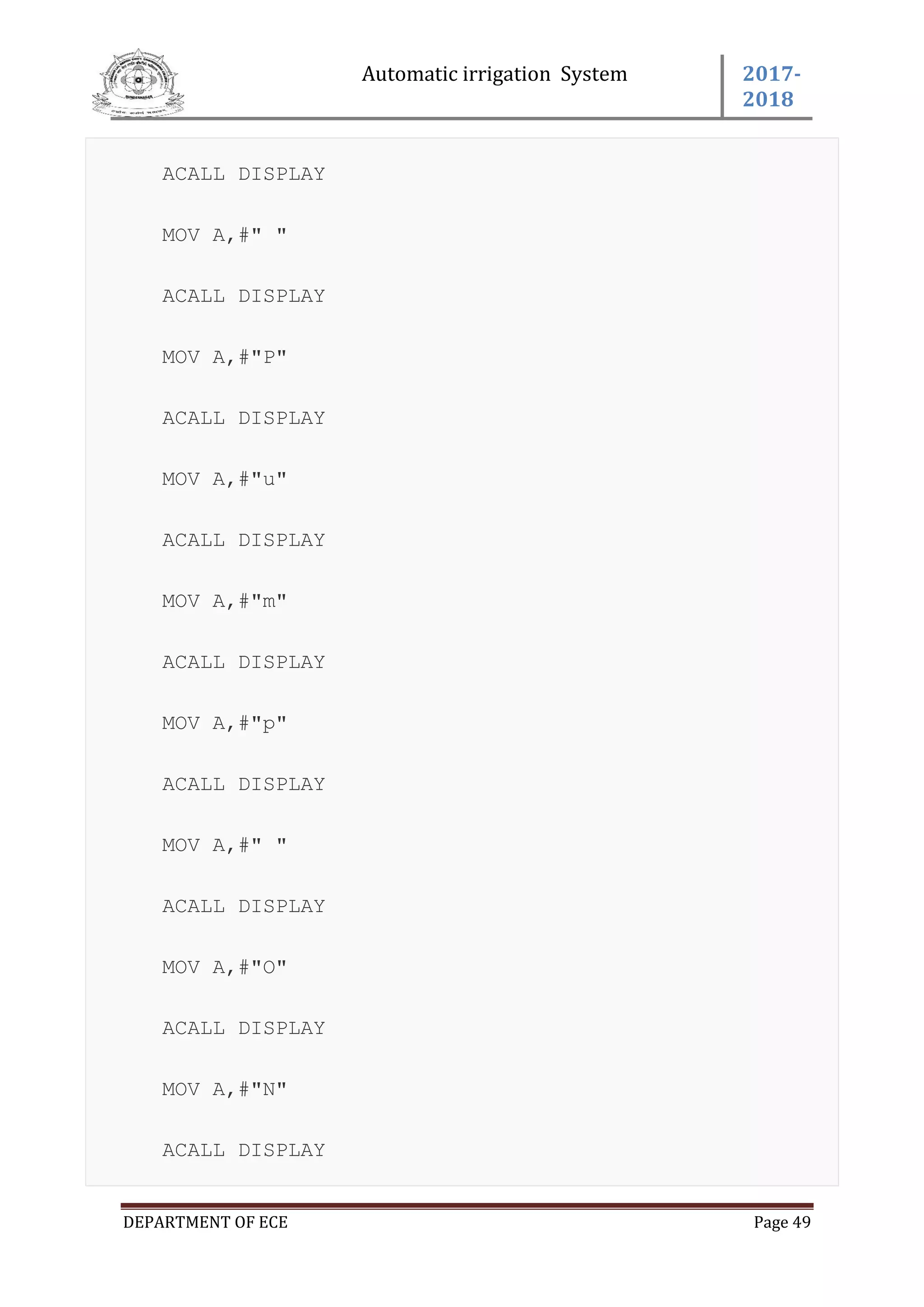

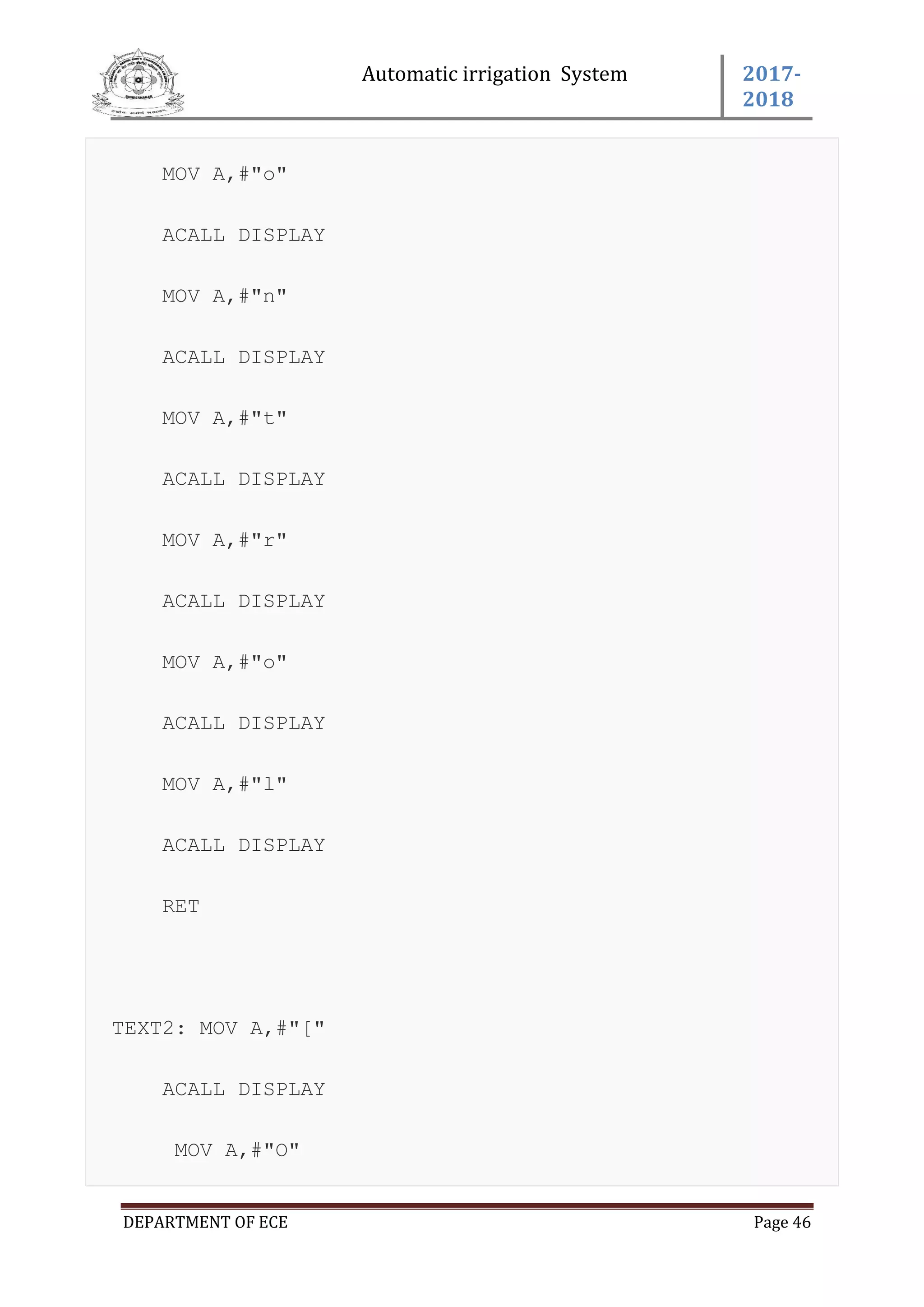

ACALL DISPLAY

MOV A,#"K"

ACALL DISPLAY

MOV A,#"]"

ACALL DISPLAY

MOV A,#" "

ACALL DISPLAY

MOV A,#"P"

ACALL DISPLAY

MOV A,#"u"

ACALL DISPLAY

MOV A,#"m"

ACALL DISPLAY

MOV A,#"p"

ACALL DISPLAY

MOV A,#" "

ACALL DISPLAY](https://image.slidesharecdn.com/automaticirrigationsystembyusing89s52-171126133818/75/Automatic-irrigation-system-by-using-89s52-47-2048.jpg)

![Automatic irrigation System 2017-

2018

DEPARTMENT OF ECE Page 48

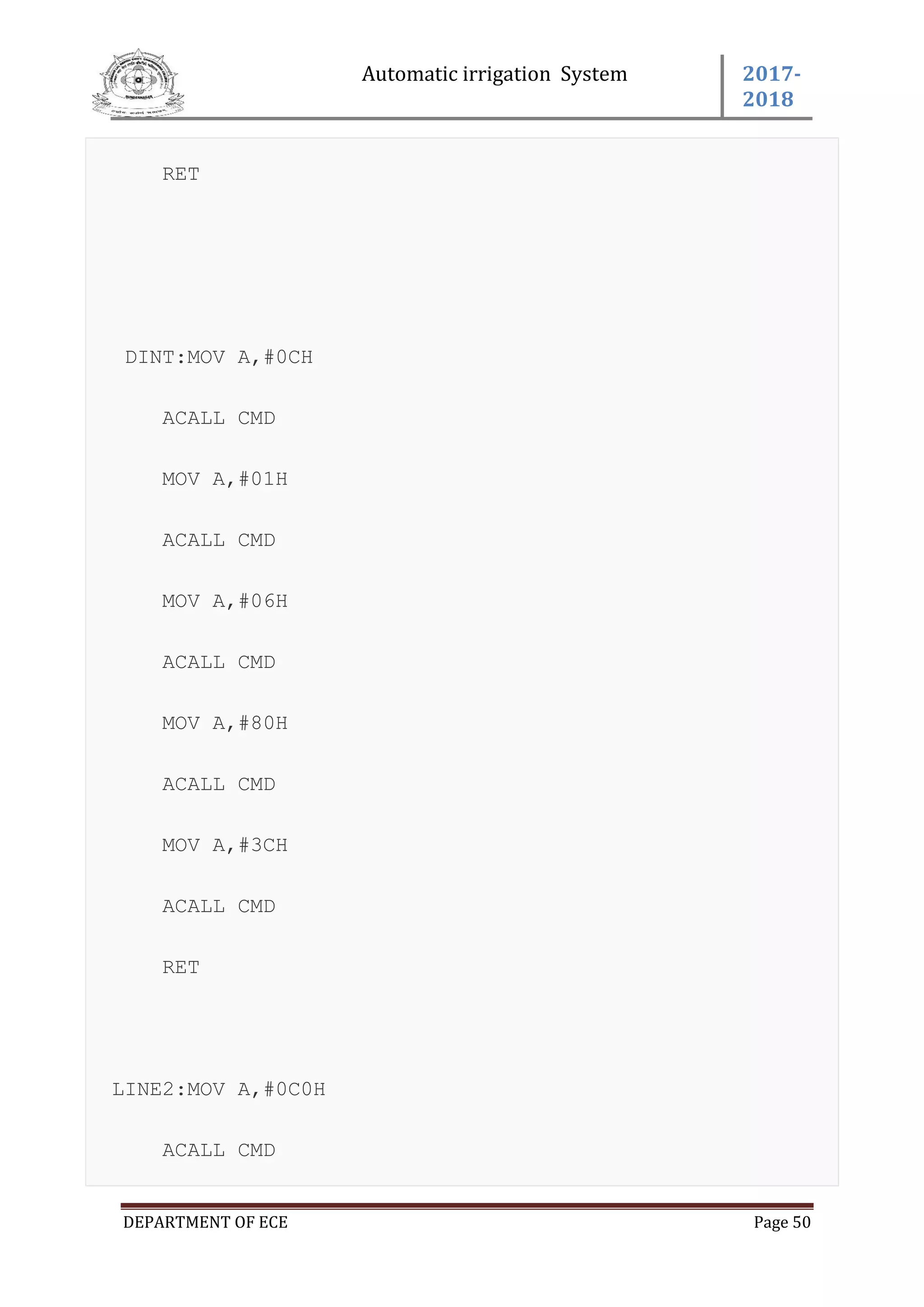

MOV A,#"O"

ACALL DISPLAY

MOV A,#"F"

ACALL DISPLAY

MOV A,#"F"

ACALL DISPLAY

RET

TEXT3: MOV A,#"["

ACALL DISPLAY

MOV A,#"L"

ACALL DISPLAY

MOV A,#"o"

ACALL DISPLAY

MOV A,#"w"

ACALL DISPLAY

MOV A,#"]"](https://image.slidesharecdn.com/automaticirrigationsystembyusing89s52-171126133818/75/Automatic-irrigation-system-by-using-89s52-48-2048.jpg)