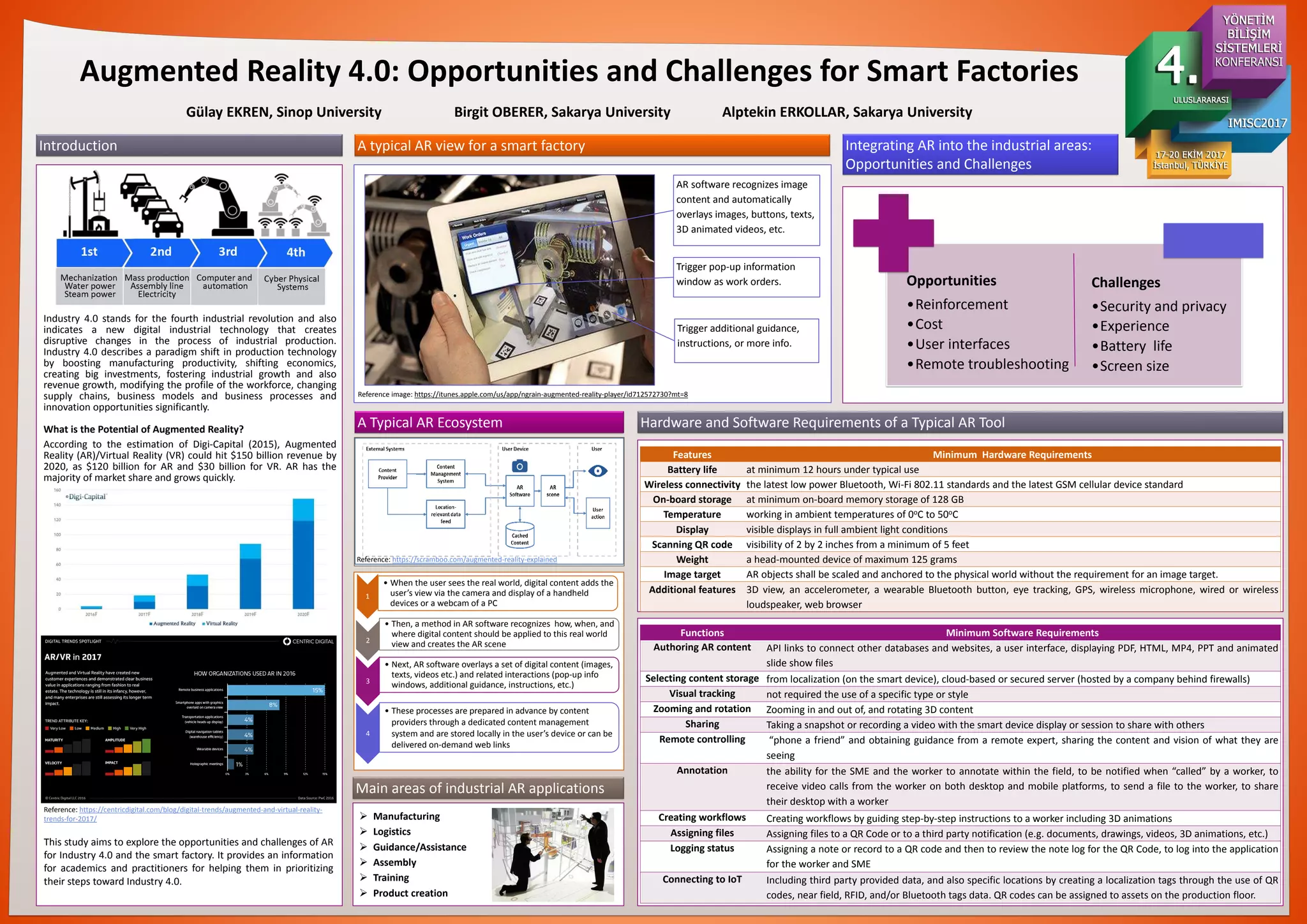

This document discusses opportunities and challenges for using augmented reality in smart factories. It describes how a typical augmented reality system works by recognizing real world images and overlaying digital content through a user's device. The document also outlines main areas for industrial augmented reality applications like manufacturing, logistics, and training. Finally, it identifies opportunities like reinforcement learning and reduced costs, but also challenges for augmented reality in industries like security, user experience, battery life, and screen size.