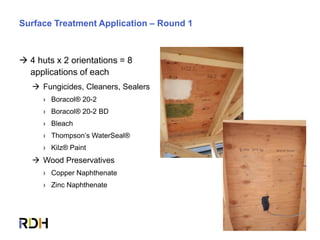

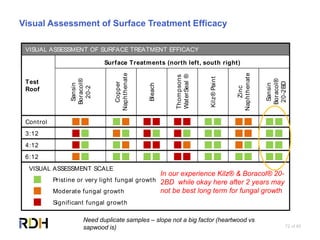

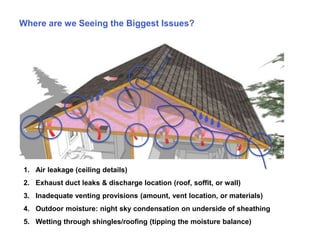

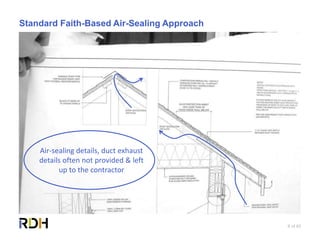

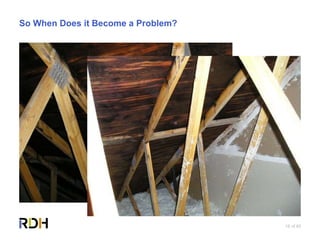

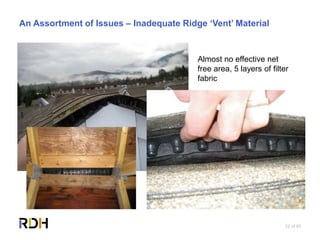

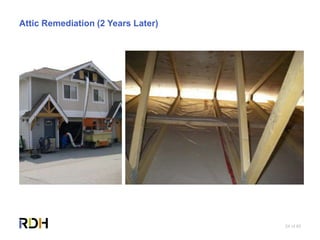

The document discusses the performance of ventilated attics, highlighting key problems related to moisture issues caused by factors such as air leakage, inadequate ventilation, and outdoor moisture sources like night sky condensation. A case study is presented that illustrates typical attic complications and remediation strategies, including air sealing and surface treatments to manage mold growth. The findings emphasize that elevated moisture in attics often exceeds the drying capacity provided by ventilation, necessitating effective design and maintenance practices.

![48 of 85

Results – Long Term Roof Sheathing Moisture Contents

0

5

10

15

20

25

30

09-2012

10-2012

11-2012

12-2012

01-2013

02-2013

03-2013

04-2013

05-2013

06-2013

07-2013

08-2013

09-2013

10-2013

11-2013

12-2013

01-2014

02-2014

03-2014

MoistureContent[%]

MC-FULL-S-CONT MC-FULL-S-312 MC-FULL-S-412

MC-FULL-S-612 EMC (1 wk)](https://image.slidesharecdn.com/2016-170320235103/85/Attics-Problems-and-Solutions-48-320.jpg)

![55 of 85

When Does it Occur?

0

100

200

Oct 02 Oct 03 Oct 04 Oct 05 Oct 06

S

Solar Radiation CONDENSE-Plywood-312

Increa

0

5

10

15

20

25

30

Oct 02 Oct 03 Oct 04 Oct 05 Oct 06

MoistureContent[%]andTemperature[°C]

Condensation

0

5

10

15

20

25

30

Oct 02 Oct 03 Oct 04 Oct 05 Oct 06

MoistureContent[%]andTemperature[°C]

MC-FULL-N-312 MC-IN-SURF-N-312 T-IN-N-312-Plywood

T-N-312-Embedded Outdoor - Temperature Outdoor - Dewpoint

COND-N-312 Sheathing Solar Radiation

Condensation](https://image.slidesharecdn.com/2016-170320235103/85/Attics-Problems-and-Solutions-55-320.jpg)

![57 of 85

When Does it Occur?

0

100

200

300

400

Oct 02 Oct 03 Oct 04 Oct 05 Oct 06

SolarR

Solar Radiation CONDENSE-Plywood-312

IncreasingSu

0

5

10

15

20

25

30

Oct 02 Oct 03 Oct 04 Oct 05 Oct 06

MoistureContent[%]andTemperature[°C]

Condensation

0

5

10

15

20

25

30

Oct 02 Oct 03 Oct 04 Oct 05 Oct 06

MoistureContent[%]andTemperature[°C]

MC-FULL-N-312 MC-IN-SURF-N-312 T-IN-N-312-Plywood

T-N-312-Embedded Outdoor - Temperature Outdoor - Dewpoint

COND-N-312 Sheathing Solar Radiation

Condensation

0

100

200

300

400

500

600

700

800

900

1000

Oct 02 Oct 03 Oct 04 Oct 05 Oct 06

SolarRadiation[W/m2]

Solar Radiation CONDENSE-Plywood-312

IncreasingSurfaceCondensation

20

25

30

mperature[°C]

20

25

30

emperature[°C]

0

100

200

Oct 02 Oct 03 Oct 04 Oct 05 Oct 06

Solar Radiation CONDENSE-Plywood-312

Inc

0

5

10

15

20

25

30

Oct 02 Oct 03 Oct 04 Oct 05 Oct 06

MoistureContent[%]andTemperature[°C]

Condensation

0

5

10

15

20

25

30

Oct 02 Oct 03 Oct 04 Oct 05 Oct 06

MoistureContent[%]andTemperature[°C]

MC-FULL-N-312 MC-IN-SURF-N-312 T-IN-N-312-Plywood

T-N-312-Embedded Outdoor - Temperature Outdoor - Dewpoint

COND-N-312 Sheathing Solar Radiation

Condensation

Heavy Condensation

Daily Solar Radiation

Cycles

Dry

Light Condensation](https://image.slidesharecdn.com/2016-170320235103/85/Attics-Problems-and-Solutions-57-320.jpg)

![62 of 85

On the Flip Side: Solar Heat Gain & Drying Potential

0

5

10

15

20

25

30

35

40

45

50

55

60

Aug 21 00:00 Aug 21 06:00 Aug 21 12:00 Aug 21 18:00 Aug 22 00:00

Temperature[°C]

Temperatures - 3:12 and 6:12 Slope Roofs - Early Spring Conditions

T-OUT-N-612-Shingle

T-OUT-S-612-Shingle

T-IN-N-612-Plywood

T-IN-S-612-Plywood

T-OUT-N-312-Shingle

T-OUT-S-312-Shingle

T-IN-N-312-Plywood

T-IN-S-312-Plywood

Outdoor - Dewpoint

Outdoor - Temperature

South Shingles 55°C

North Shingles

35-40°C

South Sheathing = 35°C

North Sheathing = 31°C

Ambient

Air up to

21°C

Lots of cloud cover changes the wetting and drying balance.](https://image.slidesharecdn.com/2016-170320235103/85/Attics-Problems-and-Solutions-62-320.jpg)