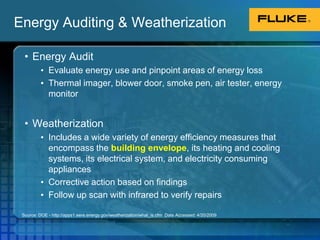

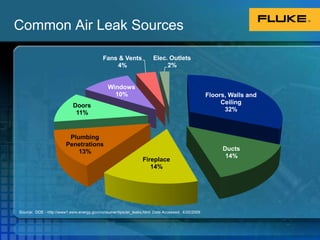

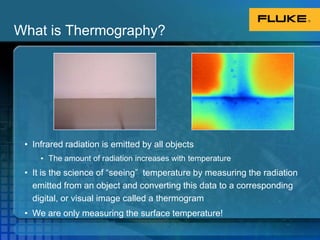

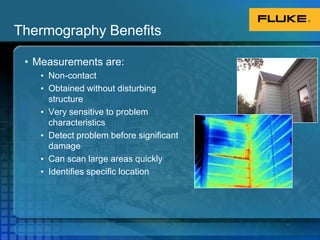

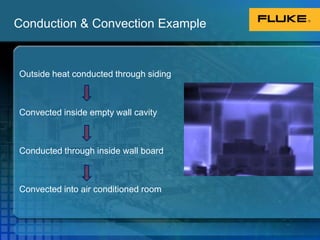

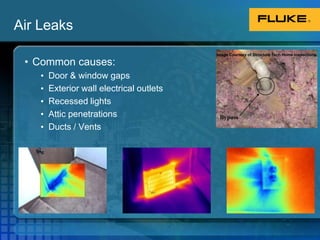

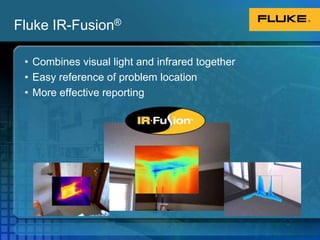

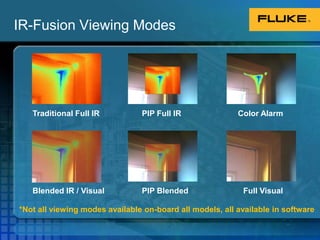

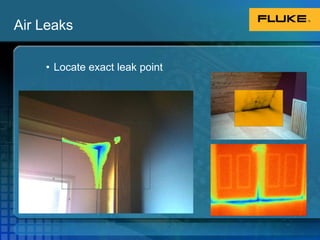

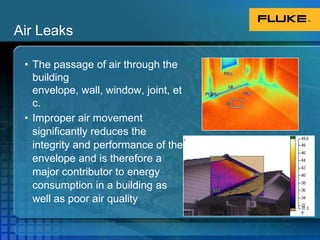

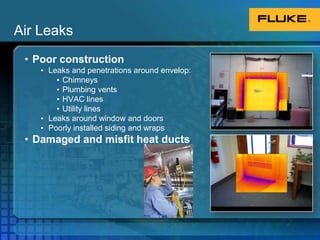

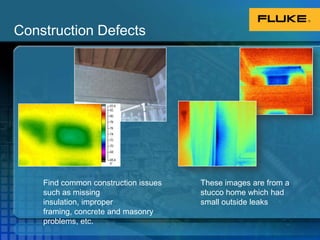

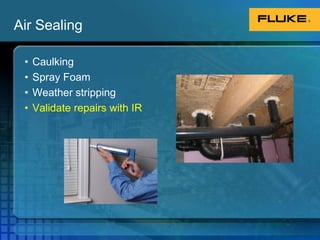

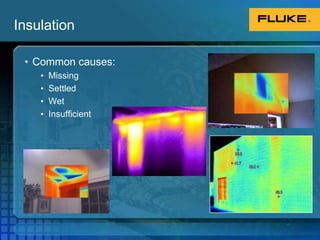

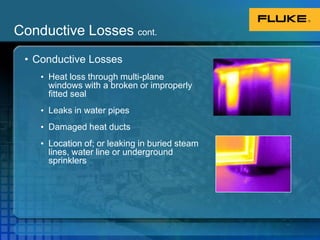

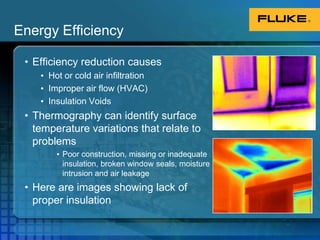

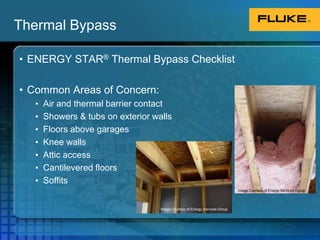

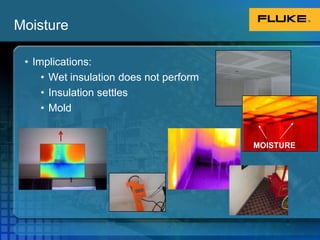

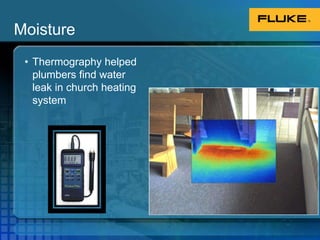

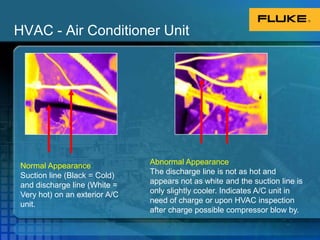

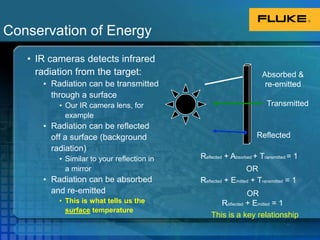

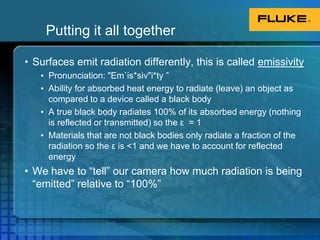

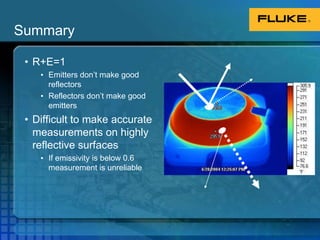

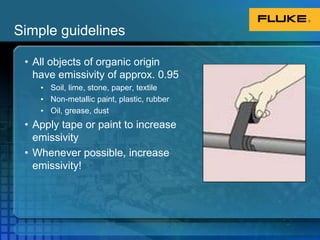

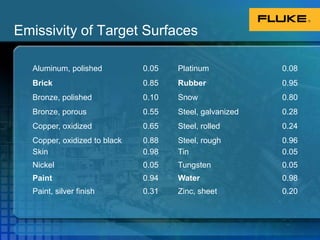

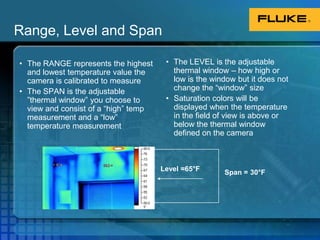

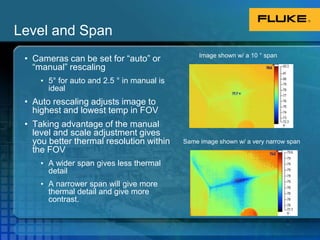

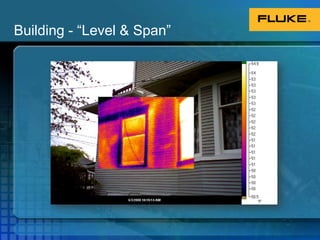

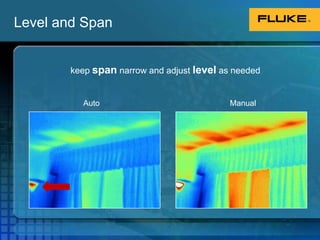

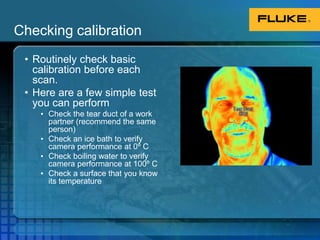

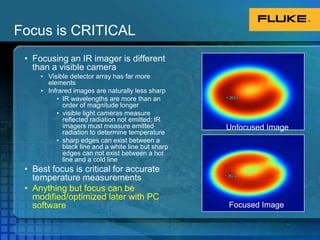

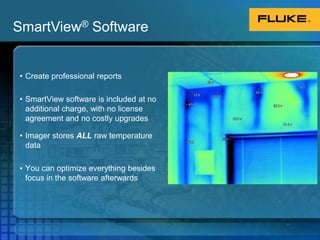

Thermal imaging can be used for energy auditing and weatherization to locate air leaks, moisture issues, and other problems. An energy audit uses tools like a thermal imager, blower door, and other equipment to evaluate energy usage and pinpoint areas of energy loss. Weatherization involves sealing leaks and improving insulation. Thermal imaging makes inspections easier and more effective by allowing users to quickly scan areas and see problems like missing insulation or air leaks without disturbing structures. It provides visual documentation of issues found before and after repairs. Focusing the thermal imager properly and understanding parameters like level, span, and emissivity are important for capturing accurate temperature data.