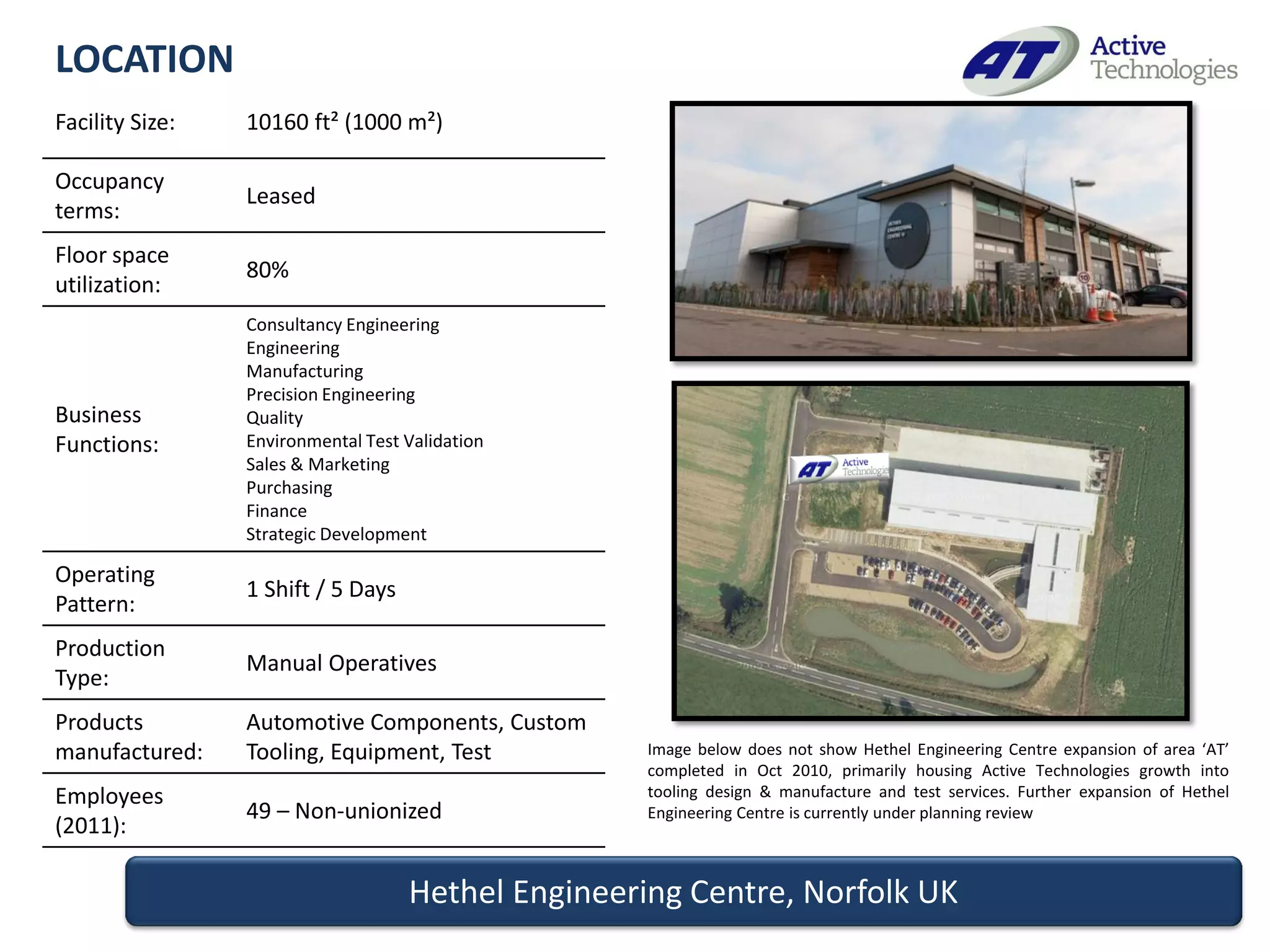

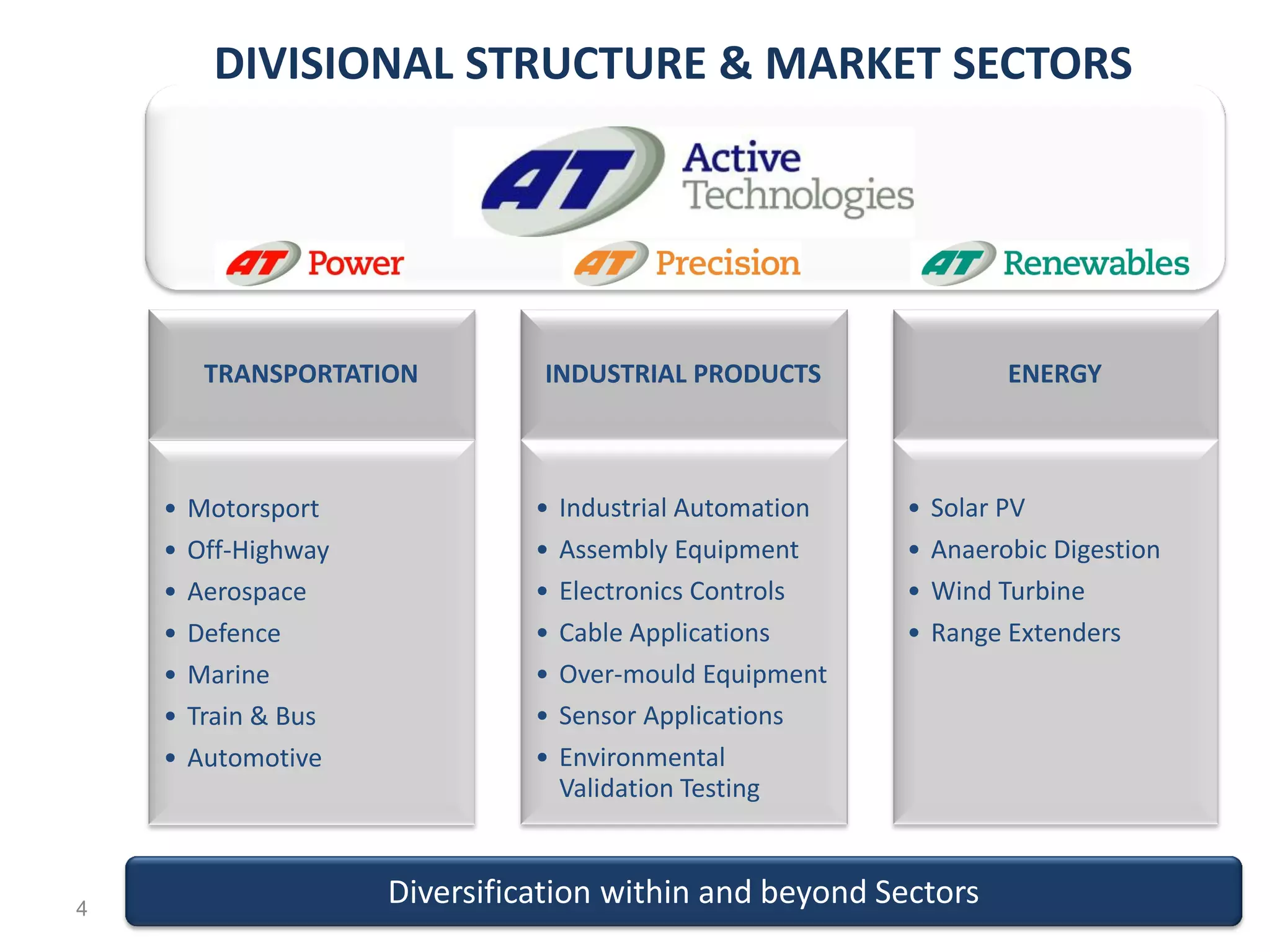

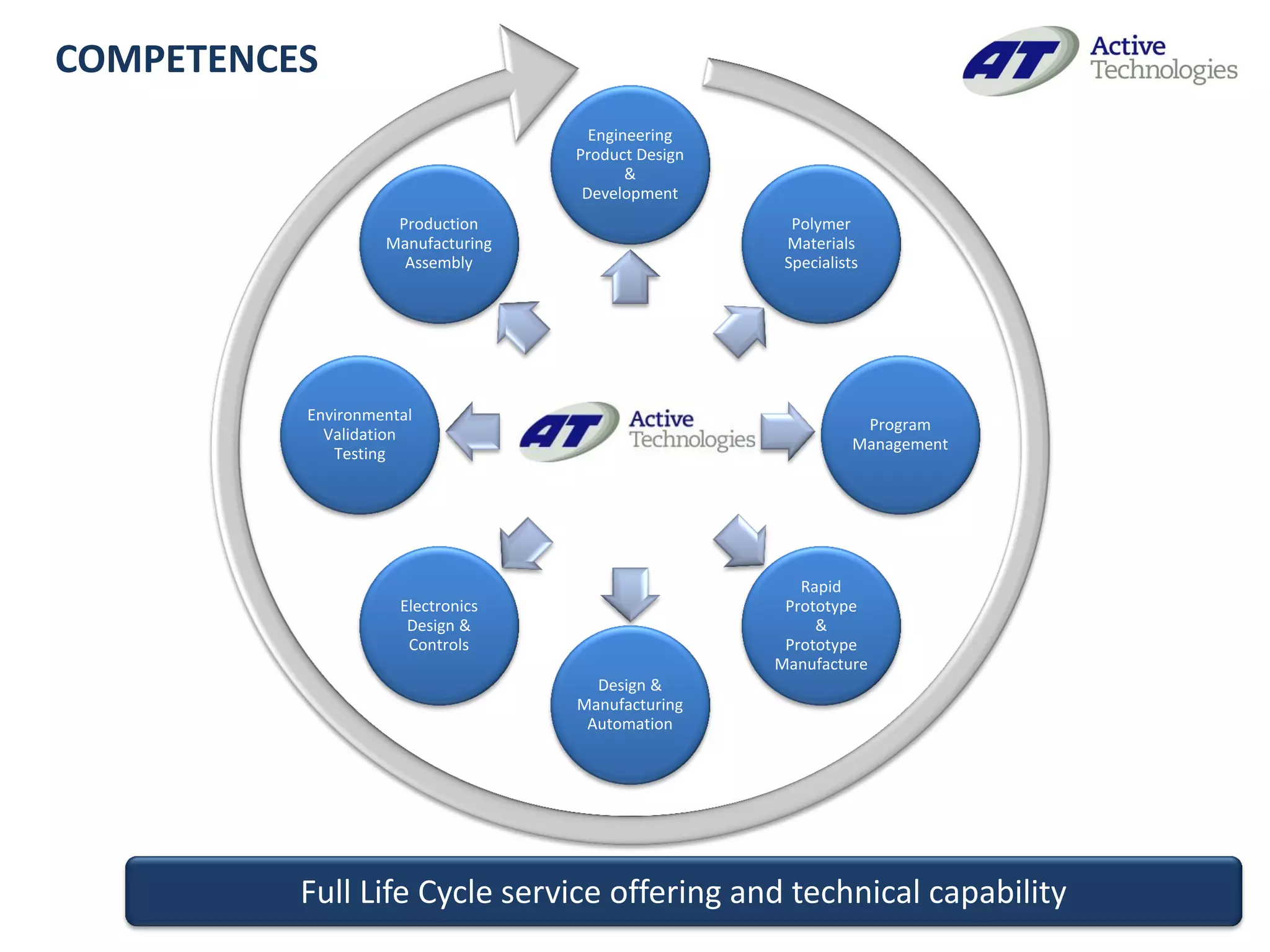

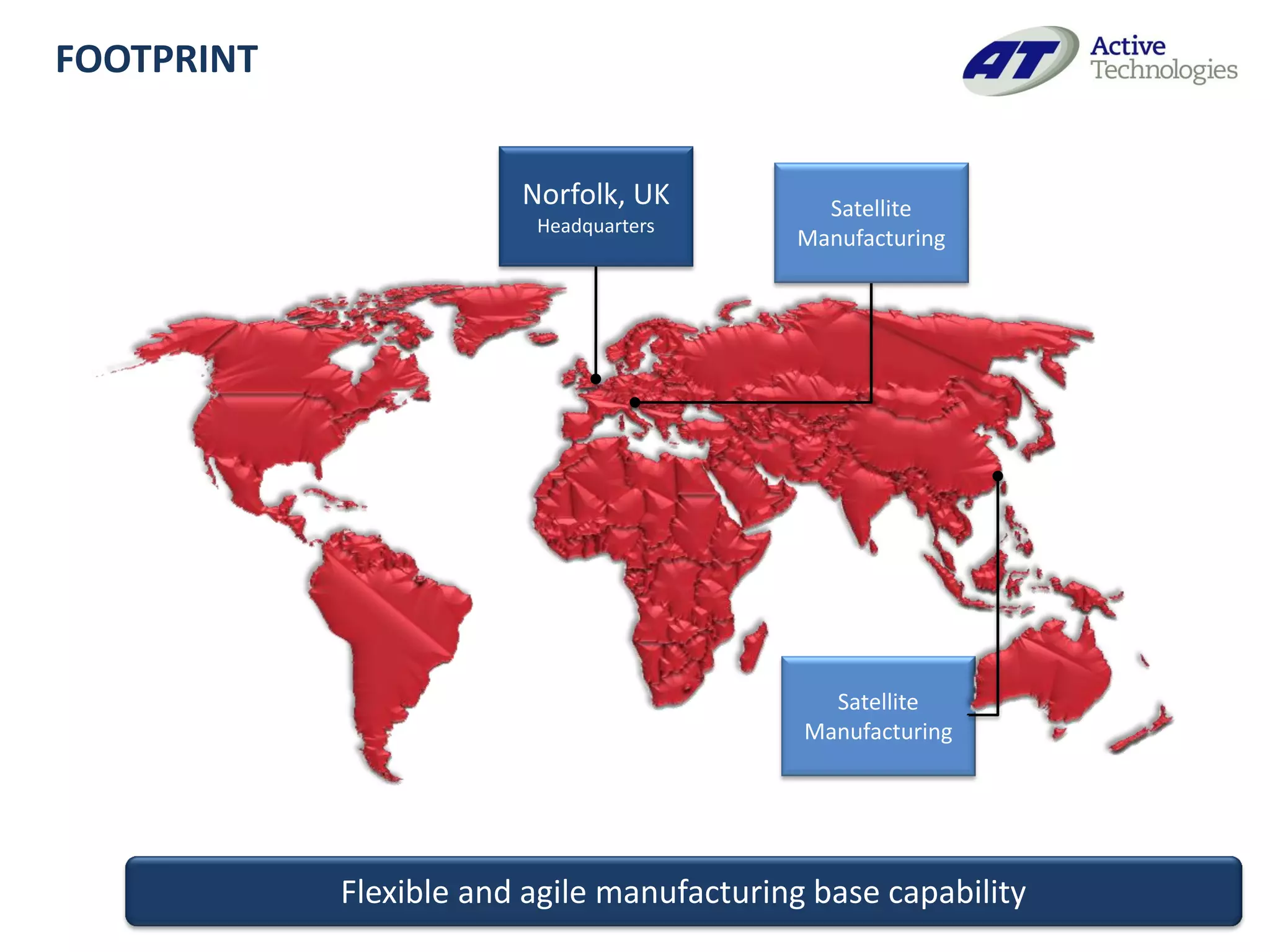

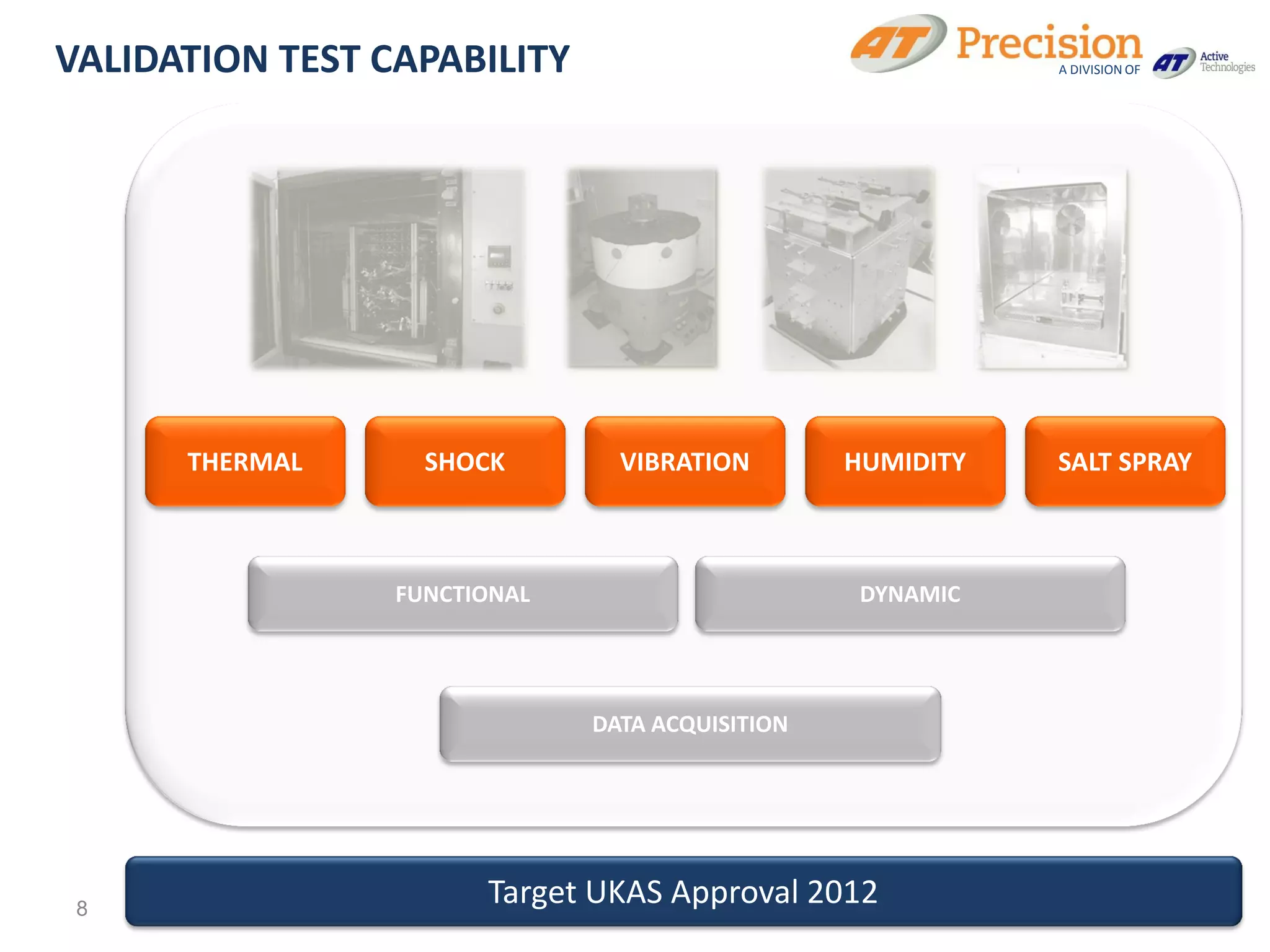

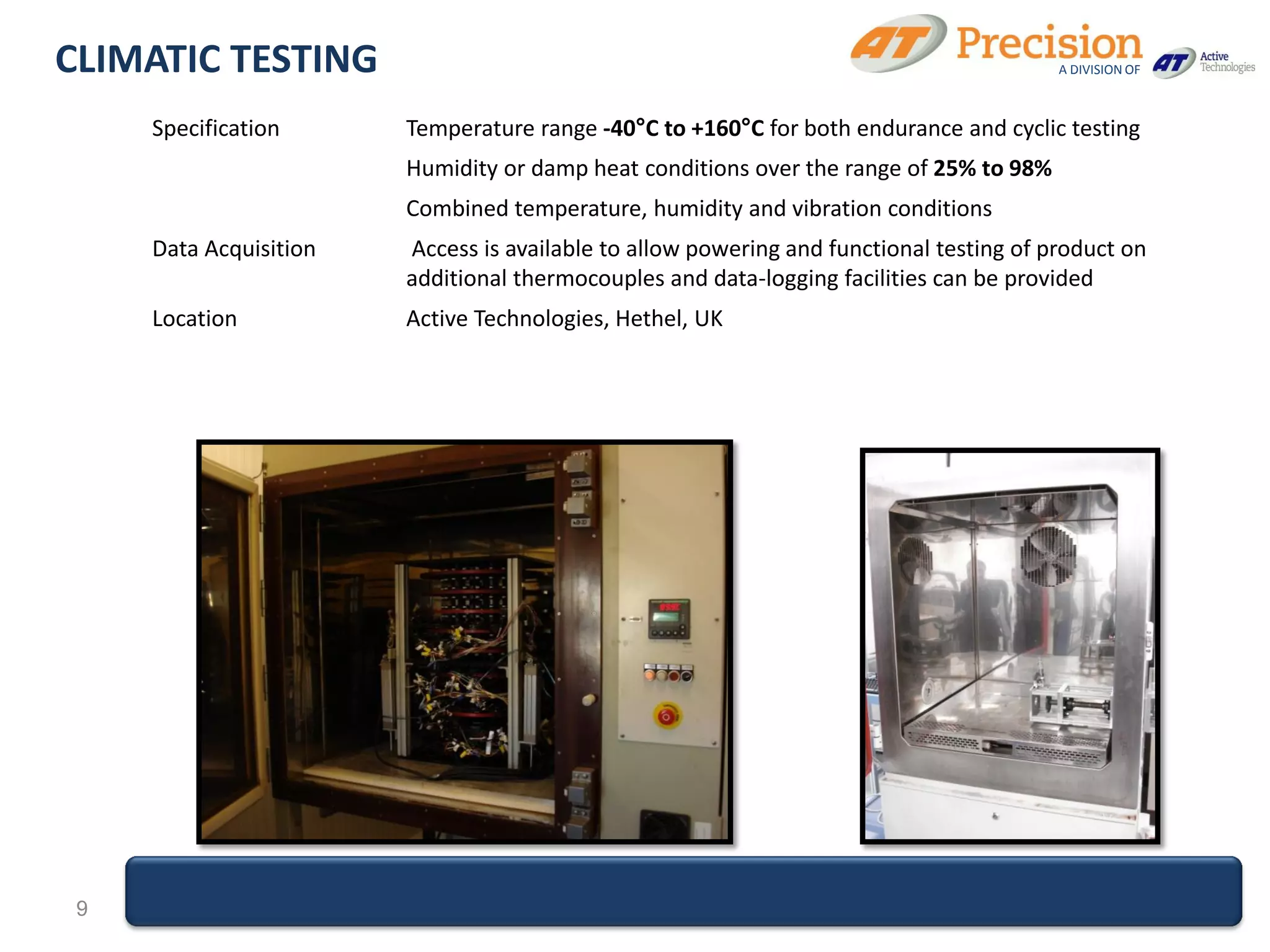

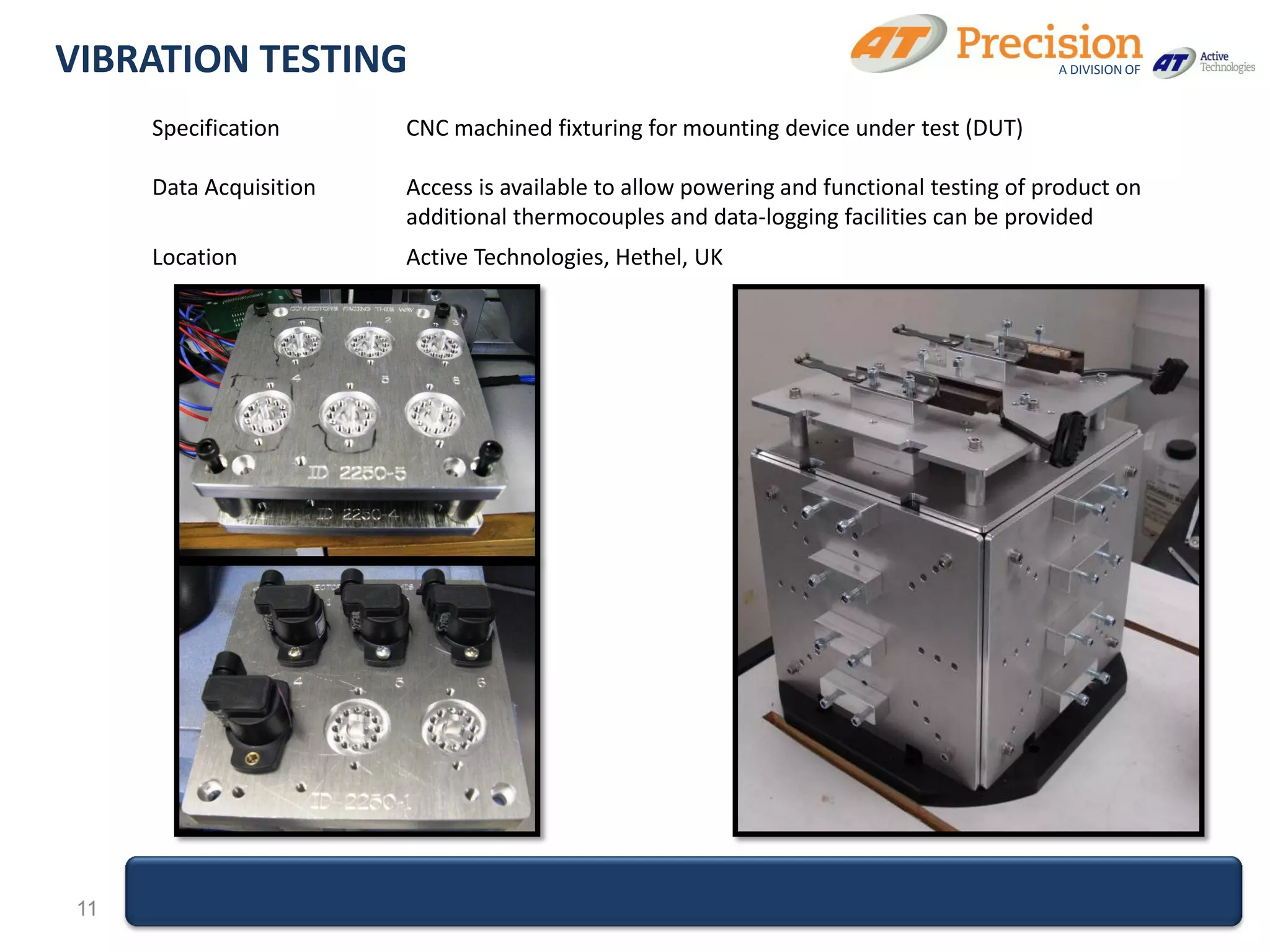

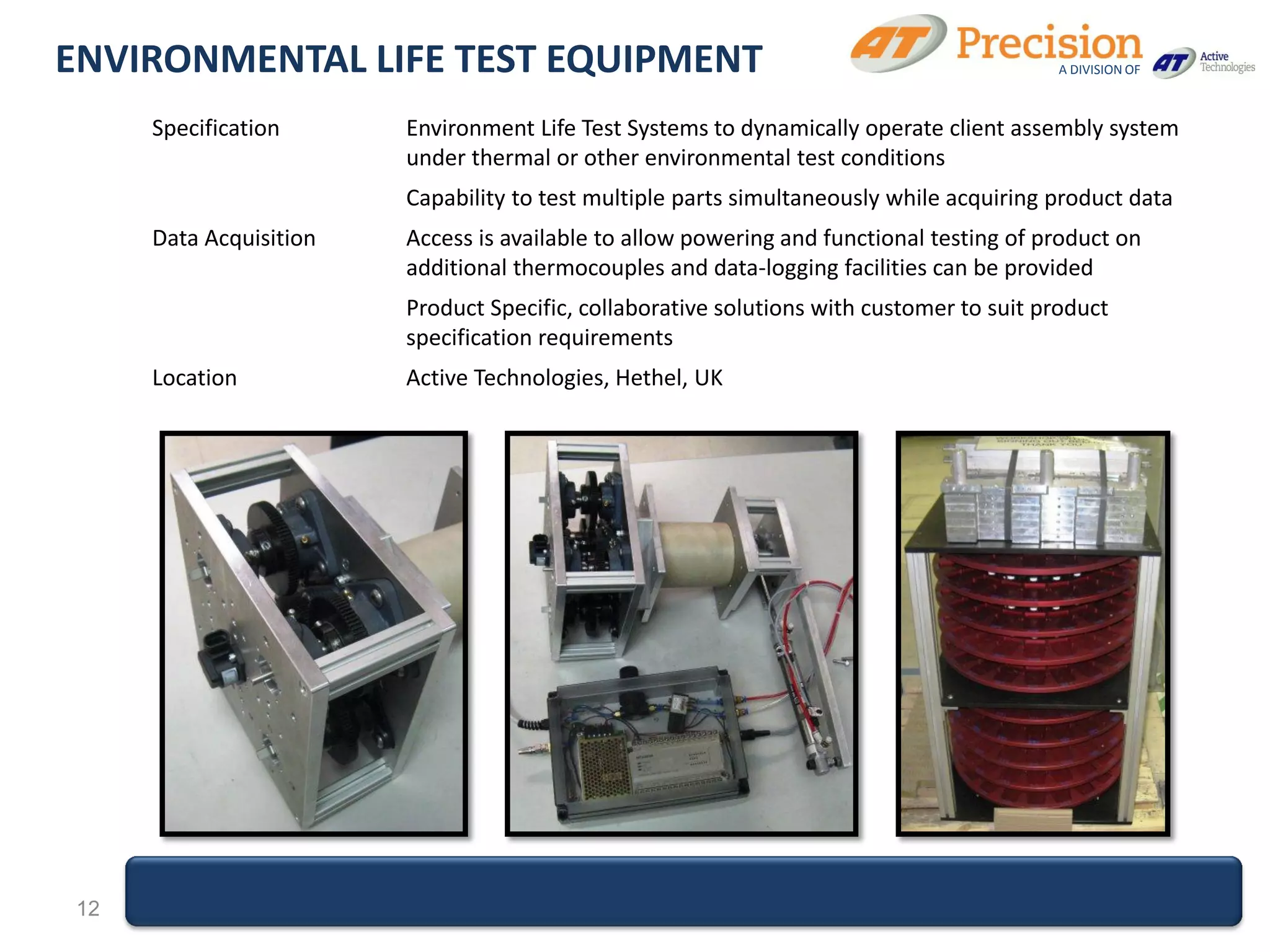

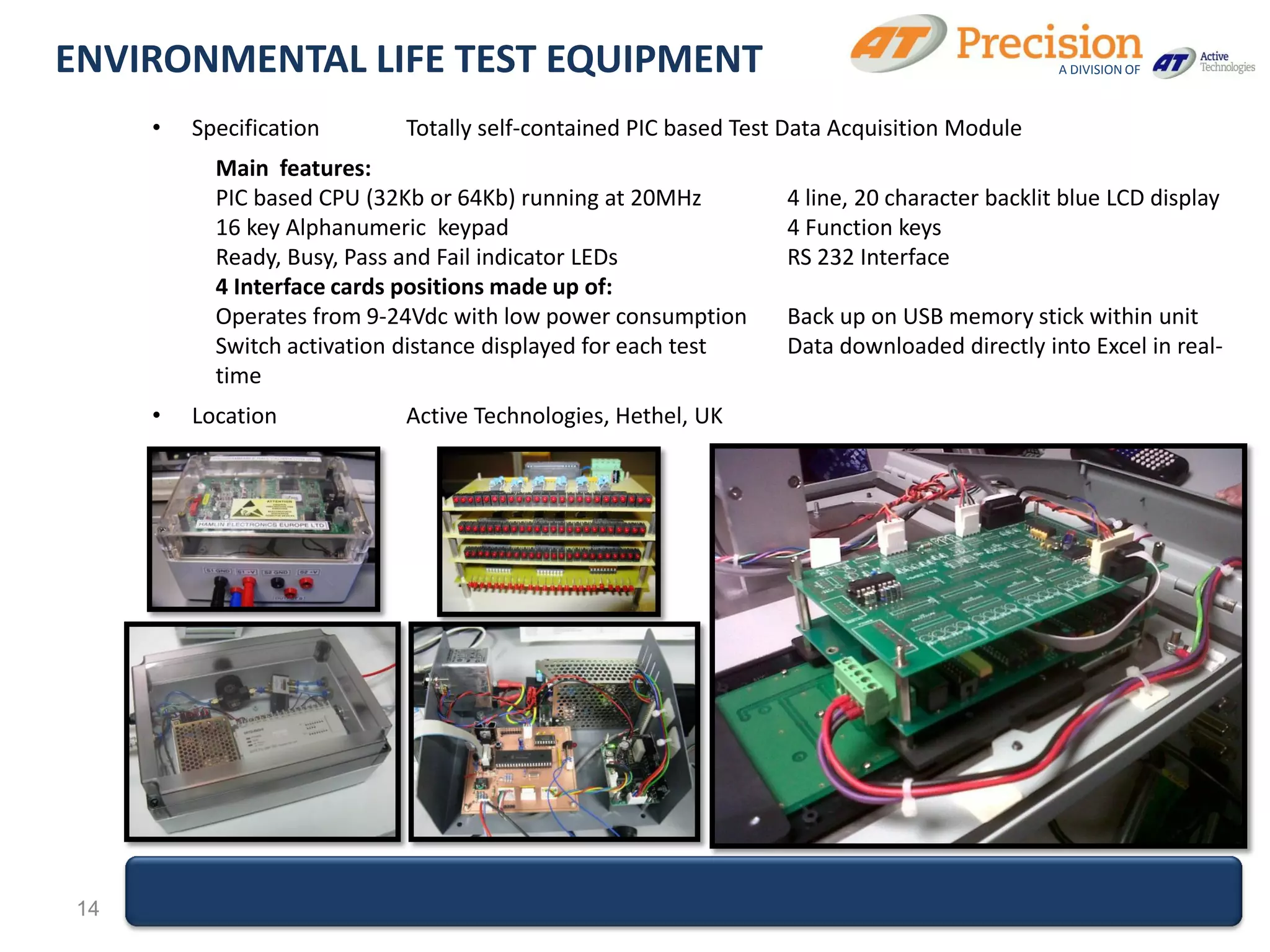

Hethel Engineering Centre in Norfolk, UK, spans 10,160 ft² and specializes in precision engineering, consultancy, and environmental test validation. Established in 2005, the company has expanded its capabilities, including establishing a tooling division and environmental testing services, achieving significant revenue growth while diversifying into multiple sectors such as automotive and aerospace. The center is planning further expansions to enhance its manufacturing and testing facilities.