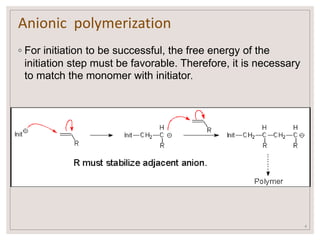

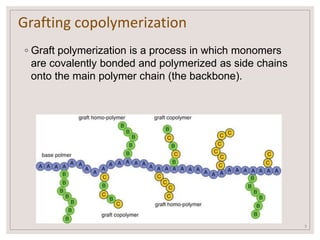

This document summarizes the synthesis of a well-defined alternating copolymer of 1,1-diphenylethylene (DPE) and tert-butyldimethylsilyloxymethyl substituted styrene (St-TBS) by anionic copolymerization. The temperature and monomer ratio were important in controlling the copolymer structure and suppressing homopolymerization of the styrene derivatives. Various graft copolymers with controlled side chain densities were then synthesized using the alternating copolymer backbone and both "grafting from" and "grafting onto" methodologies. Characterization techniques like MALDI-TOF-MS, SEC, NMR and DSC confirmed the

![Conclusion

◦ Successful synthesis controlled alternating copolymers

◦ The temperature and monomer ratio of [DPE]/[St-TBS] are

important factors for controlling the resulting structure.

◦ The bulky TBS functionality efficiently suppressed the

formation of St–St homopolymerization.

◦ With the help of Grafting the group synthesize a wide

variety of side-chain-density-controlled graft copolymers

as model compounds.

17](https://image.slidesharecdn.com/anionicalternatinggraftcopolymerization-191120043323/85/Anionic-alternating-graft-copolymerization-17-320.jpg)