This document describes an experiment to synthesize copolymers of myrcene with maleic anhydride or tert-butyl acrylate using nitroxide mediated polymerization with NHS-BlocBuilder initiator. Myrcene/maleic anhydride copolymerization was unsuccessful likely due to a side Diels-Alder reaction between the monomers. Myrcene/tert-butyl acrylate copolymerizations with varying monomer feed compositions were more controlled. Analysis of the copolymers found decreasing molecular weight and low polydispersity as the tert-butyl acrylate content increased, possibly due to intramolecular backbiting terminations.

![4

2. Introduction

With the fast development of the modern technologies, the demands for materials with high

performance and versatility have been dramatically increased in the last few decades. Polymers,

due to their mechanical flexibility and low production costs, have contributed a considerably

portion to the synthesis of these materials. While the current chemical processes of polymer

synthesis are mainly based on the bulk chemicals such as carbon monoxide, hydrogen, ethylene,

propylene and benzene, obtained from oil and gas[1]

, there is an increasing emphasis to use

monomers from sustainable resources like myrcene[2]

and pinene[3]

. In particular, poly(myrcene)

P(My), exhibiting a significant average molar mass, behaves like a rubber such as poly(isoprene)

or poly(butadiene). However, due to myrcene’s non-polar structure (Figure 1), the adhesion and

reactive blending for example of poly(myrcene) with polar polymeric materials are not

remarkable. To compensate this defect and expand its usage, certain polar monomers need to

be copolymerized with myrcene. Functional groups like anhydrides (borne by MA) or carboxylic

acids (borne by acrylic acid) can be copolymerized with non-polar monomers such as myrcene or

isoprene. In the first part of the project, maleic anhydride bearing anhydride functional group

was going to copolymerize with myrcene. In the second part, tert-butyl acrylate (Figure 1) was

going to be introduced to copolymerize with myrcene. Note that we used tert-butyl acrylate

(tBuA) instead of acrylic acid (AA). Indeed, the sensitivity of the SG1 free nitroxide toward

strong acids such as AA is problematic (SG1 consumed in degradative side reactions with AA).

Rather than copolymerizing AA directly with myrcene, it is more facile to first copolymerize

tBuA with My, followed by cleavage of the protecting group to yield AA functional groups (well-

known and efficient deprotection with trifluoroacetic acid).

In order to achieve the two different copolymers exhibiting desirable average molecular

weights and a high degree of livingness (capability of the copolymer to re-initiate a fresh batch

of monomer), the copolymerizations must proceed in a controlled manner. One traditional

method was ionic polymerization, in which a strong base (anionic polymerization) or a strong

acid (cationic polymerization) served as the initiator, and thanks to the strong reactivity of the

ions, each polymer chain can be initiated and propagate simultaneously, which achieves the

mono-dispersity of the polymers. However these highly reactive ions also increased the

sensitivity to solvent, temperature and impurities[4]

, leading to an increase in the cost for

purification and in the difficulties for the experimental operation. In addition, ionic

Figure 1: Myrcene (left), maleic anhydride (middle) and tert-butyl acrylate (right) monomers.](https://image.slidesharecdn.com/49072bc5-0cdb-4522-b853-65d170457f92-160520182827/75/Lab-report-4-2048.jpg)

![5

polymerization is restricted to monomers which do not have interference on the polymerization.

For example, monomers with strong acidic groups tend to react with the counter-ions which

could cause the failure in terminating the reaction. The acrylic acid group in tert-butyl-acrylate is

one of these group. Therefore, the ionic polymerization method could not be applied in this

experiment[5]

. One alternative method that could also proceed the copolymerization in a

controlled manner is termed controlled radical polymerization. The controlled radical

polymerization combines the control of microstructure from ionic polymerization and the ease

of industrial implementation from other types of polymerizations such as free radical

polymerization or addition polymerization[5]

. Thus using controlled radical polymerization could

avoid the rigorous requirements on the solvent, temperature and impurities that ionic

polymerization had, and it has proven to be capable of polymerizingmyrcene and tert-butyl-

acrylate[5]

.

There are three major types of living/controlled polymerization termed nitroxide-mediated

radical polymerization (NMP), atom-transfer radical polymerization (ATRP), and reversible

addition-fragmentation chain-transfer polymerization (RAFT). Because of the poisoning of ATRP

catalyst by acrylic acid, ATRP cannot be applied here, and RAFT requires the chain transfer

agents that are not currently commercially available. Therefore, among the three variants, NMP

was going to be applied in this experiment[5]

.

Depending on the type of monomers being polymerized, the initiators used in NMP can be

different. For example, first-generation nitroxide mediators such as TEMPO (2,2,6,6-

tetramethylpiperidinyl-1-oxy) are used for the polymerization of mostly styrenic-based

monomers, and it is not effective to control the polymerization of acrylates and methacrylate[6].

In this experiment, NHS-BB (Figure 2) is going to be used as it has been proven to be capable of

controlling the homopolymerization of butyl acrylates.

Figure 2: NHS-BlocBuilder (left) and SG1 free nitroxide (right)[6]

.

In order to sufficiently understand the kinetics and analyze the results, the overall conversions

of the monomers and the individual conversions of myrcene and tert-butyl-acrylate (or maleic

anhydride) were determined. In this project, the overall conversions were achieved by

measuring the empty vial weight, the vial weight with monomer solution and polymer inside

(wet vial weight) and the vial weight after completely drying out the monomer solution (dry vial

weight) and calculating the gravimetric differences. The gravimetric difference of dry vial weight

and empty vial weight gives the mass of polymer (product), and the gravimetric difference of

wet vial weight and empty vial weight gives the mass of monomers and polymer (product +](https://image.slidesharecdn.com/49072bc5-0cdb-4522-b853-65d170457f92-160520182827/75/Lab-report-5-2048.jpg)

![7

3. Experimental Procedure

3.1. Materials

Basic alumina (Brockmann, Type 1, 150 mesh) and calcium hydride (90-95% reagent grade)

were purchased from Aldrich. 2-Methyl-2-[N-tert-butyl-N-(1-diethoxyphosphoryl-2,2-

dimethylpropyl)-aminoxy]–N-propionyloxy-succinimide, also known as NHS-BlocBuilder, was

synthesized in the laboratory from 2-{tert-Butyl[1-(diethoxyphosphoryl)-2,2-

dimethylpropyl]aminogoxy)-2-methylpropanoic acid, also known as BlocBuilderTM

(MAMA-SG1,

99%, acquired from Arkemaand used without further purification), N-hydroxy-succinimide(NHS,

98%, from Aldrich and used as received) and N,N’-dicyclohexylcarbodiimide(DCC, 99%, from

Aldrich and used as received). Myrcene(My, ⩾90%) and maleic anhydride (MA, 99%) were

obtained from Sigma-Aldrich and used as received. Tert-butyl acrylate (tBuA, 98%) obtained

from Aldrich was purified by passage through a column of calcium hydride and basic alumina

mixture (1:20 by weight, respectively) and stored in a sealed flask in a refrigerator under a head

of nitrogen. Methanol (MeOH, 99.9%) was obtained from Fisher Scientificand used as received.1,

4-dioxane (ACS reagent, >99.0%) was obtained from Sigma-Aldrich and used as

received.Chloroform-d1(CDCl3, 99.8%) for NMR measurements was purchased from Merck

KGaA. Tetrahydrofuran (THF, 99.9%, HPLC grade) for GPC measurements was purchased from

Fischer Scientific.

3.2. Syntheses

3.2.1. Initial feed for myrcene/maleic anhydride

Copolymerization

Two polymerizations were performed with different initial myrcene and maleic anhydride molar

compositions. The feed conditions were listed in Table 1. Because maleic anhydride is solid at

room temperature unlike myrcene at the liquid state, 1,4-dioxane was added as solvent to

dissolve maleic anhydride monomer and ensure a homogeneous reaction medium (myrcene

totally miscible in this solvent). The target number average molecular weight (Mn,target) at 100%

overall conversion was approximately 30 kg/mol and was calculated by the initial moles of

monomers relative to the moles of NHS-BlocBuilder initiator.

Table 1 Experimental conditions myrcene /maleic anhydride copolymerization

in 1,4-dioxane at 115℃ using NHS-Blocbuilder as initiator.

Experiment

ID

[NHS-

Blocbuilder]0

[Myrcene]0

[Maleic

Anhydride]0

[1,4-

dioxane]

fmyrcene

a Mn-

,target

b

mol L-1

mol L-1

mol L-1

mol L-1

mol%

kg

mol-1

My-MA

90-10

0.017 2.133 2.133 5.761 50 30

My-MA

50-50

0.015 2.981 0.331 5.454 90 30](https://image.slidesharecdn.com/49072bc5-0cdb-4522-b853-65d170457f92-160520182827/75/Lab-report-7-2048.jpg)

![8

a

Initial molar composition with respect of myrcene. b

Number average molecular weight at

100% overall conversion determined by gel permeation chromatography (GPC).

3.2.2. Initial feed for myrcene/tert-butyl acrylate

copolymerization

Four copolymerizations with the use of different myrcene and tert-butyl acrylate monomer

compositions were performed as shown in Table 2. The monomers were purified by basic

alumina and calcium hydride. NHS-BlocBuilder was used as initiator and the amount was set

constantly to 0.25g for each case. The target number average molecular weight of the final

product at 100% overall conversion was approximately 40 kg/mol and was calculated by the

moles of monomers relative to the moles of NHS-BlocBuilder initiator.

Table 2 Experimental conditions of the bulk copolymerizations of myrcene

and tert-butyl acrylate at 115℃ using NHS-Blocbuilder as initiator

Experiment

ID

[NHS-Blocbuilder]0 [Myrcene]0 [Tert-Butyl acrylate]0 fmyrcene

a

Mn,target

b

mol L-1

mol L-1

mol L-1

mol% kg mol-1

My-tBuA

0-100

0.022 0.000 6.889 0 40

My-tBuA

50-50

0.021 3.157 3.157 50 40

My-tBuA

70-30

0.020 4.277 1.833 70 40

My-tBuA

90-10

0.020 5.328 0.592 90 40

a

Initial feed molar composition with respect of myrcene. b

Number average molecular weight

at 100% overall conversion.

3.2.3. General Synthesis Procedure

The syntheses were all performed in a 50 mL 3 neck round bottom glass flask equipped with a

condenser, thermal well and magnetic Teflon stir bar. The chilling liquid inside the condenser

was 90 v% water and 10 v% glycol, and the chilling temperature was set to 3 ℃ to sufficiently

condense any vapors produced in order to prevent from any monomer loss during the

experiment. The condenser was connected to the middle neck of the flask and was capped with

a rubber septum at the top which had a needle placed to relieve the pressure of the nitrogen

purge that was applied during the entire course of the reaction. The glass flask was placed inside

the heating mantle, which was equipped on the top of the magnetic stirrer. A specific

formulation for an initial feed composition of myrcene (fmyrcene,0) equal to 50 mol% was given as

an example. The masses of NHS-BlocBuilder (0.25 g, 0.523 mmol), myrcene (10.78 g, 79.124

mmol) and t-BuA (10.14 g, 79.124 mmol) were measured inside a disposable vial and transferred

into the reactor which was then sealed with a rubber septum (in the case of myrcene/maleic

anhydride copolymerization, 1,4-dioxane and myrcene were firstly measured and transferred

into the reactor, and the maleic anhydride was slowly added into the mixture due to the](https://image.slidesharecdn.com/49072bc5-0cdb-4522-b853-65d170457f92-160520182827/75/Lab-report-8-2048.jpg)

![10

4. Results and discussion

4.1. Myrcene/maleic anhydride copolymerization

In general, copolymerization kinetics is characterized as 1st

-order kinetics as illustrated in

Equation 2, and the logarithm of 1/(1-x) should linearly increase as the reaction time increases.

Where M0 is the initial monomer concentration; Mt is the monomer concentration after time t;

<kp> is the average propagation rate constant; x is the overall conversion; [P∙] is the propagating

radical concentration and t is the time.

However, as shown in Figure 3, the experimental data with both an initial feed concentration of

50mol% myrcene (fmyrcene0 =0.5) and 90mol% myrcene(fmyrcene0 =0.9) do not steady increase in

ln(1/(1-x)) and instead, apparent fluctuations are presented in the series of data points. Besides,

surprisingly, at time of 0 min, very high conversions (around 30% for fmyrcene=0.9 and around 70%

for fmyrcene=0.5) are observed. Due to the strong contradictions between the experimental

observations and the general polymerization theories, there is a large possibility of the failure

on the copolymerization process of myrcene and maleic anhydride.

Figure 3: Semi-logarithmic kinetic plot of ln((1-x)-1) (x = overall conversion) versus time for various initial

myrcene/maleic anhydride (My/MA) molar compositions polymerized at 115 o

C.

One rationale of the unexpected results could be the occurrence of a side reaction, and the

most possible side reaction, considering the conditions of the experiments, is the Diels-Alder

reaction. Generally speaking, the Diels-Alder reaction is an organic chemical reaction between a

conjugated diene and a substituted alkene[7]

and the general form is illustrated in Figure 4.

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

0 50 100 150 200 250 300

ln(1/(1-x))

Time (min)

My-MA 90-10

My-MA 50-50

My-MA 90-10

My-MA 90-10

ln (

𝑀0

𝑀𝑡

) = ln (

𝑀0

𝑀0(1 − 𝑥)

) = ln (

1

1 − 𝑥

) =< 𝑘 𝑝 > [𝑃 ∙]𝑡 Equation 2](https://image.slidesharecdn.com/49072bc5-0cdb-4522-b853-65d170457f92-160520182827/75/Lab-report-10-2048.jpg)

![11

Figure 4: The Diels-Alder reaction.

In this experiment, myrcene (7-Methyl-3-methylene-1,6-octadiene) is a diene and maleic

anhydride (Furan-2,5-dione) bears a reactive double bond, which satisfy the conditions of the

Diels-Alder reaction. The plausible reaction equation is presented in Figure 5.

According to the literature, Diels-Alder reaction can happen at low temperature (40o

C) and

generate high yield of adduct (25%)[8]

. Therefore, during the heating up process, the Diels-Alder

reaction may have already started and converted significant amount of monomers before the

initiation of the copolymerization. Therefore, at time of 0min, which is in our case defined

arbitrarily when the temperature reaches 90o

C, a high conversion of monomers has been

achieved. In addition, kinetics of the Diels-Alder reaction is proven to be an overall 2nd

order as

shown in Equation 3[9]

, where [My] is the myrcene concentration and [MA] is the maleic

anhydride concentration.

When the total concentration of myrcene and maleic anhydride stays the same ([My] + [MA] = a

constant), the closer [My] and [MA] are to each other, the larger the product of them is, and the

higher the rate of production will be. This explains why the starting conversion is higher when

fmyrcene0 is 50% than when fmyrcene0 is 10%.

The other possible contribution to the errors may be due to the impurities, mainly ring

structure dienes, in myrcene monomer. In the literature[10]

, regarding isoprene/mA

copolymerization, the cyclopentadiene effectively inhibits the stereospecific polymerization of

isoprene if presents in amount of higher than 10ppm. Based on the similarities in the structure

between isoprene and myrcene, it could be hypothesized that similar inhibitions are possible to

happen during My/MA copolymerization, which involved the myrcene with only 90% purity.

𝑑𝑃

𝑑𝑡

= 𝑘[𝑀𝑦][𝑀𝐴] Equation 3

+

Figure 5: Schematic for mycene/maleic anhydride Diels-Alder reaction](https://image.slidesharecdn.com/49072bc5-0cdb-4522-b853-65d170457f92-160520182827/75/Lab-report-11-2048.jpg)

![12

To avoid these failures due to the possible reasons mentioned above, several modifications on

the experimental procedure can be made. Firstly, using 4-methoxy-2,4-dimethylvaleronitrile

(AMVN) as the radical initiator and twisting the diene functional group to be “cis” instead of

“trans” has been proven to give high yield of copolymerization and effectively retard the Diels-

Alder side reaction[8]

. Secondly, the side product could be removed. For instance,

cyclopentadiene, side product achieved after copolymerizing isoprene with maleic anhydride,

can be removed. This resulting adduct is separated by decantation and distillation[10]

. Similar

principle could be applied to myrcene to remove the impurities the same way.

For fMA0 = 0.10, the copolymerization was very slow and uncontrolled. After 6h, the copolymer

exhibited Mn = 5 500g.mol-1 at 46% overall conversion instead of 14 000g.mol-1 theoretically. For

fMA0 = 0.50, it was even worse since no polymerization occurred (absence of polymer peak in the

GPC chromatograms).

4.2. Myrcene/tert-Butyl acrylate copolymerization

The kinetic results of My/tBuA copolymerization using NHS-Blocbuilder as the initiator are

presented in Figure 6. All copolymerization follow 1st

-order kinetic behavior and the formula can

be represented as Equation 2. Therefore, by plotting ln (

1

1−𝑥

) versus time, the slope would give

<kp> [P∙]. Since in controlled radical polymerization, [P∙] could be assumed to be equal to the

concentration of the initiator, so <kp><K> can be further obtained from dividing the slope by [P∙].

Figure 6: Semi-logarithmic kinetic plot of ln((1-x)-1

) (where x = overall conversion) versus time for various

myrcene/tert-butyl-acrylate (My/tBuA) compositions polymerized at 115 o

C.

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0 100 200 300

ln(1/(1-x))

Time (min)

My-tBuA 0-100

My-tBuA 50-50

My-tBuA 70-30

My-tBuA 90-10

My-tBuA 0-100

My-tBuA 50-50

My-tBuA 70-30

My-tBuA 90-10](https://image.slidesharecdn.com/49072bc5-0cdb-4522-b853-65d170457f92-160520182827/75/Lab-report-12-2048.jpg)

![13

Table 3 shows the values of different <kp><K> with different initial tBuA feed composition. It

should be noticed that as the initial feed composition of tBuA increased, the values of the slopes

raised up, which indicates an increase in <kp><K>. Therefore, the propagation rate of myrcene is

significantly lower than the propagation rate of tBuA. A most dramatic increase is from ftBuA0 =

90% to ftBuA0 = 100% (from 0.1330 to 0.2556), and the <kp><K> does not change much from ftBuA0

= 90% to ftBuA0 = 100% (from 0.1140 to 0.1330).

Table 3 Slopes of Semi-Logarithm Plot of ln ((1-x)-1

) Versus Time for Various

Initial tBuA Feed Compositions

Experiment ID

ftBuA

a

Slopes <kp><K>

mol% L mol-1

s-1

s-1

My-tBuA 50-50 50 0.01464 0.06654

My-tBuA70-30 70 0.002395 0.1140

My-tBuA 90-10 90 0.002659 0.1330

My-tBuA 0-100 100 0.005113 0.2556

a

Initial feed composition with respect oftert-butyl-acrylate.

In Table 4, it is shown that from 0 minute to 15 minutes, there is a dramatic increase in the

conversion of tBuA (from 8.2% to 35.0%) while the increase in myrcene conversion is not as

significant (from 2.4% to 6.8%). Even though the initial feed composition of tBuA (10%) is much

lower than that of myrcene (90%), the propagation of tBuA monomers is still favored. This fact

also evidentially shows a favor on propagating tBuA, more reactive, rather than myrcene.

Table 4: Individual Myrcene and tBuA conversions at Different Times for 10%

tBuA Initial Feed Composition

Time [min] Myrcene Conversion [%] tBuA Conversion [%]

0 2.4 8.2

15 6.8 35.0

30 15.1 46.9

60 24.6 69.8

90 33.4 82.4

150 38.8 93.1

240 49.7 98.7

360 57.5 100.0

Linear average molecular weight increases with respect to the increase in overall conversion and

narrow molecular weight distribution are the characteristics generally associated with

controlled radical polymerizations. Figure 7 shows the plot of number average molecular weight

versus conversion with initial feed composition with respect to tBuA (ftBuA) of 100%. The

experimental Mn versus conversion data values are directly obtained from the GPC machine and](https://image.slidesharecdn.com/49072bc5-0cdb-4522-b853-65d170457f92-160520182827/75/Lab-report-13-2048.jpg)

![14

the corrected Mn versus conversion values are obtained by utilizing the Mark-Houwink equation

to rectify the experimental data. In this feed condition, it is observed that the experimental

results tightly follow the theoretical predicted line below the conversion of 40% and the slope

start to drop afterwards. However, this deviation in slopes is not very significant and can be

attributed to the differences in hydrodynamic volumes of poly-tert-butylacrylate and that of the

polystyrene standards that used to calibrate the GPC[6]

. After the correction, the slope was

adjusted and raised up, which decreased the deviation, which indicates a well-controlled

copolymerization condition for tBuA polymerization.

Figure 7: Number average molecular weight (Mn) versus conversion with initial feed composition with

respect to tBuA (ftBuA) of 100%.

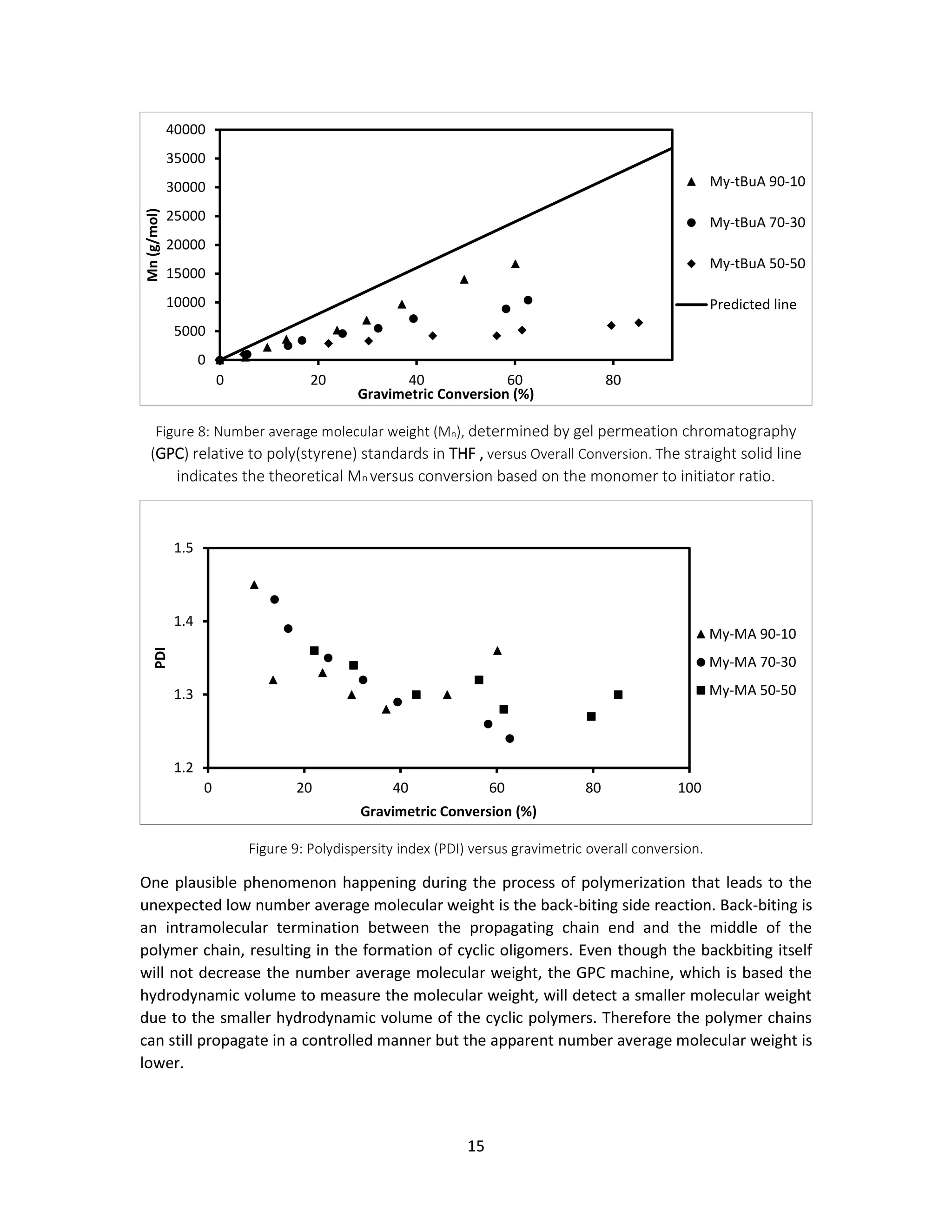

Figure 8 illustrates the number average molecular weight versus gravimetric conversion for

different initial feed compositions of myrcene (fmyrcene0). Here gravimetric conversion is used

instead of overall conversion because the peaks for the chemical shift of 5.12ppm on myrcene in

1

H NMR were failed to be detected, and therefore the conversions based on NMR are not

applicable. It is noteworthy that as fmyrcene decreases, the number average molecular weight

consistently decreases. Normally, such deviations from the predicted line indicates that the

polymerizations are not well-controlled. However, according to Figure 9, the polydispersity

indexes of the processes are all below 1.5 and trending to become steadier, which obeys the

characteristic of controlled polymerization. Thus some other factors bias the number average

molecular weight although the polymerization is well-controlled.

0

5000

10000

15000

20000

25000

30000

35000

40000

0 20 40 60 80

Mn(g/mol)

Overall conversion (%)

Experimental Mn versus conversion

Corrected Mn versus conversion

Predicted line](https://image.slidesharecdn.com/49072bc5-0cdb-4522-b853-65d170457f92-160520182827/75/Lab-report-14-2048.jpg)

![16

Several publications have shown that back-biting reactions happen frequently when tert-butyl

acrylate is involved in some anionic polymerizations and controlled radical polymerizations[11], [12],

[13]

. The rate of back-biting is a strong function of temperature, and can increase 7-fold more

when the temperature goes from 20o

C to 80o

C[13]

. Therefore, at an experimental temperature of

115 o

C, there is a high possibility that the back-biting will happen. Besides, the back-biting in

block copolymerization of methyl methacrylate and tert-butyl acrylate shows the same

characteristics on the results (low Mn, low PDI)[11]

, which proves the above hypothesis. However,

since tert-butyl-acrylate is often used for block copolymerization instead of random or

alternating copolymerization, some further experiments are required to sufficiently confirm the

hypothesis of the existence of back-biting in myrcene/tert-butyl acrylate copolymerization.](https://image.slidesharecdn.com/49072bc5-0cdb-4522-b853-65d170457f92-160520182827/75/Lab-report-16-2048.jpg)

![18

6. References

[1] A. Behr and L. Johnen, “Myrcene as a Natural Base Chemical in Sustainable Chemistry: A

Critical Review,” ChemSusChem, vol. 2, no. 12, pp. 1072–1095, Dec. 2009.

[2] J. M. Bolton, M. A. Hillmyer, and T. R. Hoye, “Sustainable thermoplastic elastomers from

terpene-derived monomers,” ACS Macro Lett., vol. 3, no. 8, pp. 717–720, 2014.

[3] K. Satoh, A. Nakahara, K. Mukunoki, H. Sugiyama, H. Saito, and M. Kamigaito,

“Sustainable cycloolefin polymer from pine tree oil for optoelectronics material: living

cationic polymerization of β-pinene and catalytic hydrogenation of high-molecular-

weight hydrogenated poly(β-pinene),” Polym. Chem., vol. 5, no. 9, pp. 3222–3230, 2014.

[4] R. J. Young and P. A. Lovell, Introduction to Polymers, 3rd ed. Taylor & Francis Group, LLC,

2002.

[5] B. H. Lessard, “Random controlled free radical copolymeriza2on of acrylic acid / styrene

and tert- -‐ butyl acrylate / styrene mixtures using nitroxide mediators By,” 2008.

[6] C. Zhang and M. Maric, “Synthesis of Stimuli-responsive, Water-soluble Poly[2-

(dimethylamino)ethyl methacrylate/styrene] Statistical Copolymers by Nitroxide

Mediated Polymerization,” Polymers (Basel)., vol. 3, no. 3, pp. 1398–1422, 2011.

[7] F. Fringuelli and A. Taticchi, The Diels–Alder Reaction. 2001.

[8] A. Tsujii, M. Namba, H. Okamura, and A. Matsumoto, “Radical alternating

copolymerization of twisted 1,3-butadienes with maleic anhydride as a new approach for

degradable thermosetting resin,” Macromolecules, vol. 47, no. 19, pp. 6619–6626, 2014.

[9] G. C. Alexander and M. E. Paulaitis, “Comment on ‘Kinetics of a Diels-Alder Reaction of

Maleic Anhydride and Isoprene in Supercritical CO2,’” J. Phys. Chem. A, vol. 107, no. 43,

pp. 9248–9249, 2003.

[10] E. Ceausescu, Stereospecific polymerization of isoprene. Pergamon Press, 1983.

[11] E. Čadová, J. Dybal, J. Kříž, P. Vlček, M. Janata, and L. Toman, “Back-Biting Termination in

Methyl Methacrylate/ tert- Butyl Acrylate Anionic Block Copolymerization,” Macromol.

Chem. Phys., vol. 209, no. 16, pp. 1657–1665, 2008.

[12] T. Ishizone, K. Yoshimura, A. Hirao, and S. Nakahama, “Controlled Anionic Polymerization

of tert -Butyl Acrylate with Diphenylmethyl Anions in the Presence of Dialkylzinc,”

Macromolecules, vol. 31, no. 25, pp. 8706–8712, 1998.

[13] B. Wenn and T. Junkers, “Kilohertz Pulsed-Laser-Polymerization : Simultaneous

Determination of Backbiting , Secondary , and Tertiary Radical Propagation Rate

Coefficients for tert -Butyl Acrylate,” pp. 1–7, 2016.](https://image.slidesharecdn.com/49072bc5-0cdb-4522-b853-65d170457f92-160520182827/75/Lab-report-18-2048.jpg)