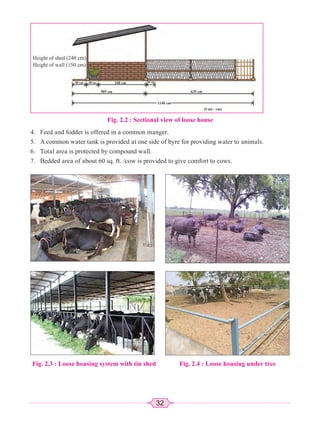

1. Routine livestock farm management practices include identifying animals, maintaining health records, providing healthcare and following scientific feeding and housing practices.

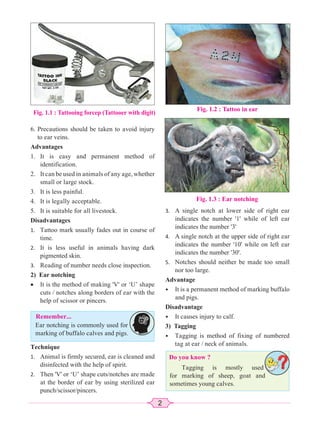

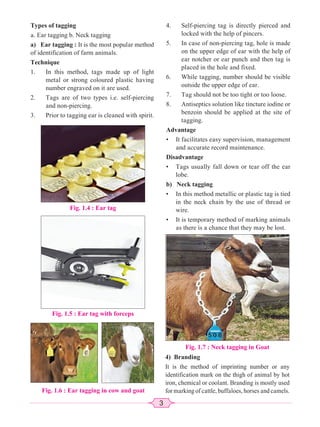

2. It is important to identify animals for record keeping, monitoring performance, and identifying lost or stolen animals. Common identification methods include ear tagging, notching, tattooing, and branding.

3. New technologies like electronic identification systems are also used for permanent identification. Proper identification allows for monitoring individual animal performance and healthcare.