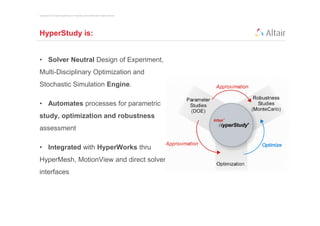

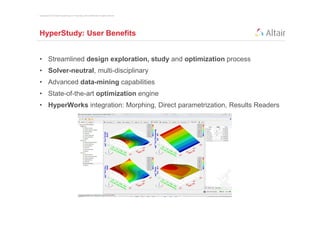

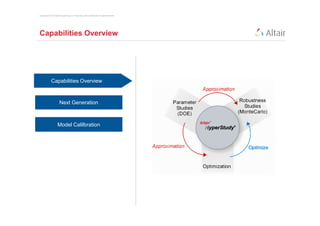

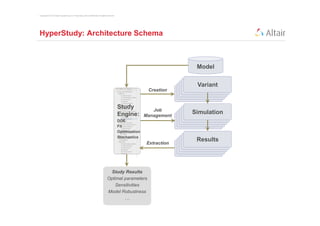

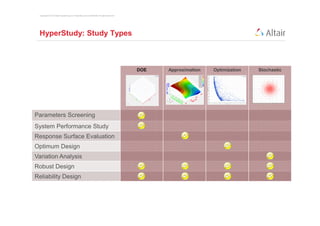

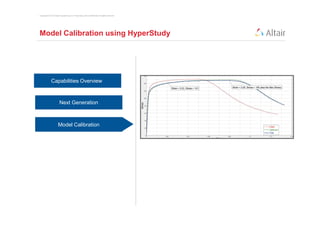

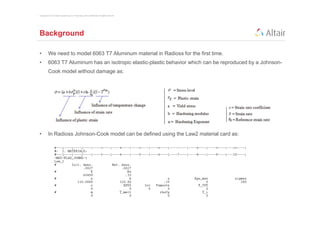

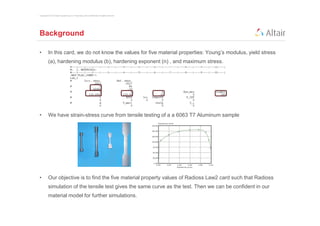

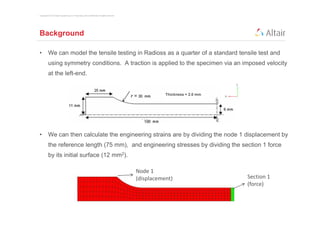

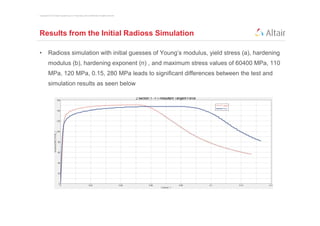

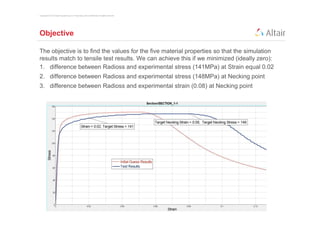

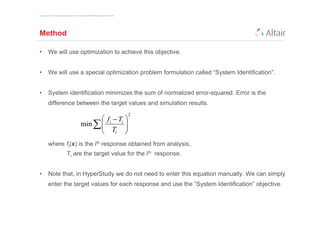

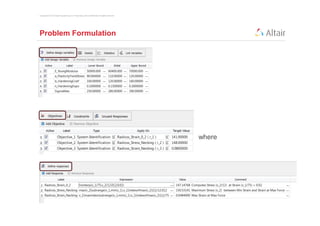

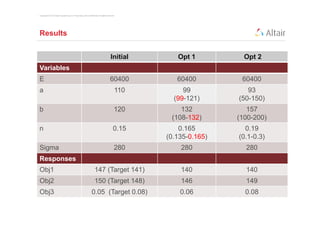

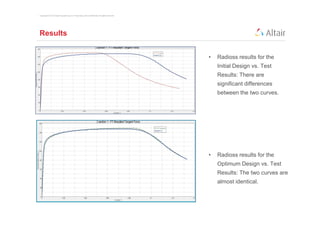

Altair HyperStudy is a solver-neutral multi-disciplinary optimization and design exploration tool. It automates parametric studies, design of experiments, and optimization to help engineers design high-performance products faster and reduce costs. The document demonstrates how HyperStudy can efficiently perform model calibration using optimization to match a physical test by adjusting material model parameters. The optimized model predictions closely match the test data, showing HyperStudy is effective for system identification problems.