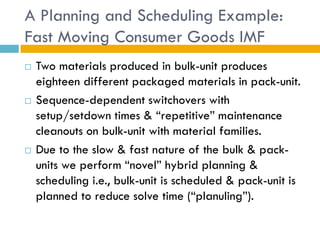

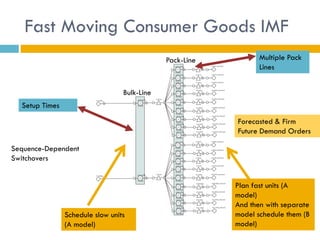

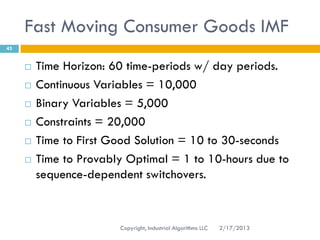

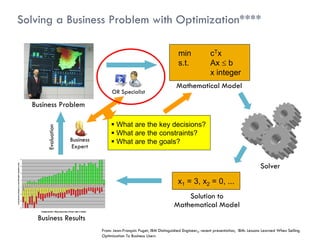

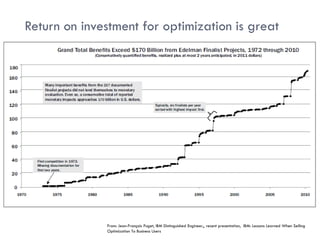

The document discusses new mathematical programming modeling and solving tools being developed by Industrial Algorithms. It outlines their mission to provide advanced modeling and solving tools for industrial applications and decision making. Industrial Algorithms licenses their IMPRESS modeling framework and solvers to operating companies, software providers, and consultants. They also offer application support and consulting services. The company collaborates academically with several universities to further develop their tools.

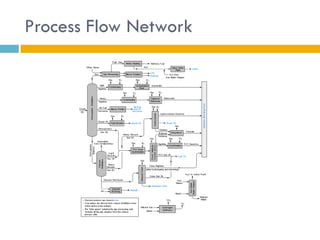

![How do we draw the chart

Use DIA Python, Open Source [Microsoft Visio]

IML, Data File

IPL, API](https://image.slidesharecdn.com/nyinformsmetrofeb2013-130217111716-phpapp02/85/NY-INFORMS-METRO-Next-Generation-of-modeling-and-Solving-Tools-31-320.jpg)