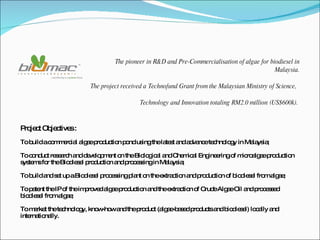

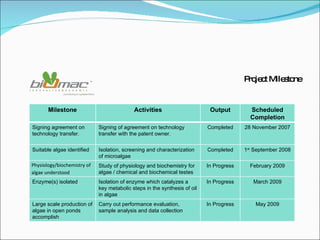

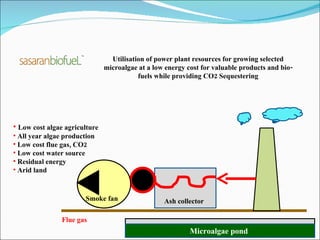

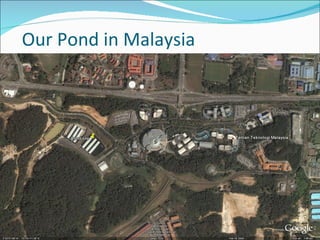

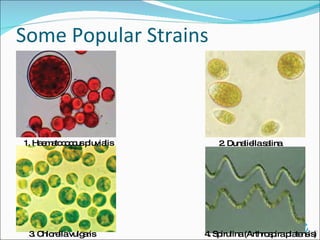

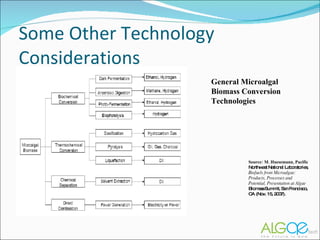

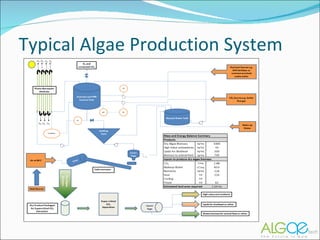

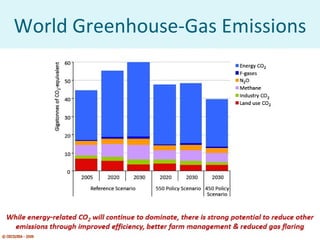

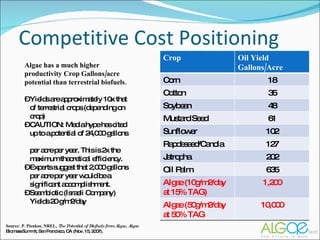

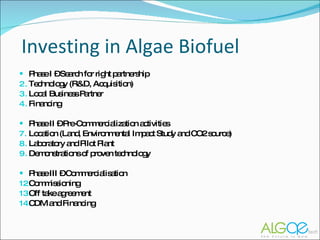

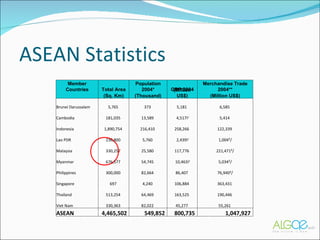

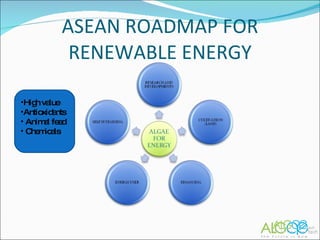

The document discusses Algaetech, a Malaysian company researching and developing microalgae production. It aims to establish a fully integrated algae cultivation operation in Malaysia and Southeast Asia. Algaetech operates an algae laboratory and production ponds. It is working to commercialize algae-based biofuels and high-value products like astaxanthin in Malaysia and establish the region's algae industry through research, technology development, and promoting regional collaboration.

![SYED ISA SYED ALWI Email : [email_address] www.algaetech.com.my www.premia.com.my](https://image.slidesharecdn.com/salvomay2009-12575273185996-phpapp01/85/Salvo-May-2009-43-320.jpg)