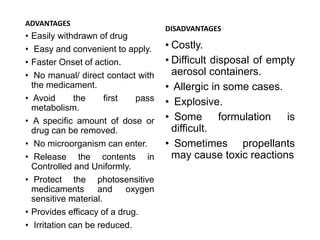

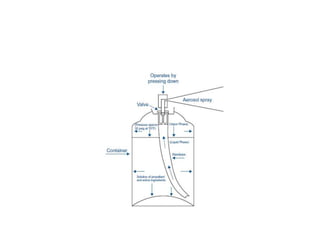

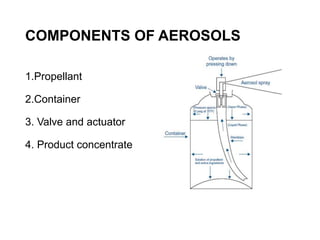

Aerosols provide advantages over other dosage forms such as easy withdrawal of medication without contamination and protection from atmospheric conditions. Aerosols contain therapeutic ingredients that are dispersed as fine particles upon actuation. They work by using a propellant to develop pressure and expel the product through a valve. Aerosols protect unstable drugs and deliver medication in a uniform, controlled manner. Common aerosol types include metered dose inhalers and dry powder inhalers used to treat respiratory conditions.