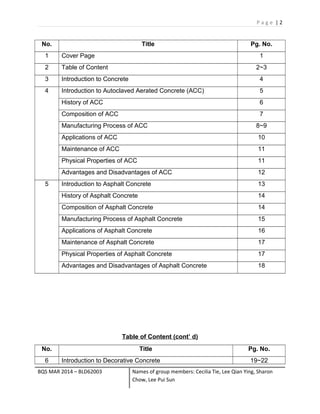

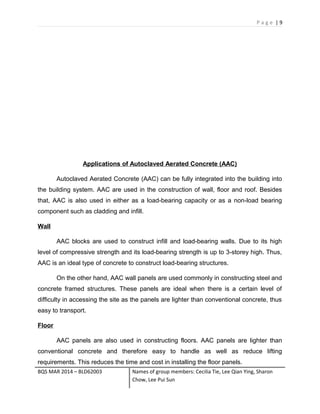

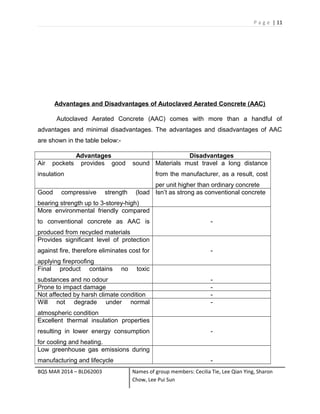

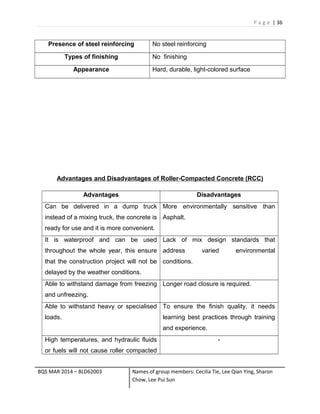

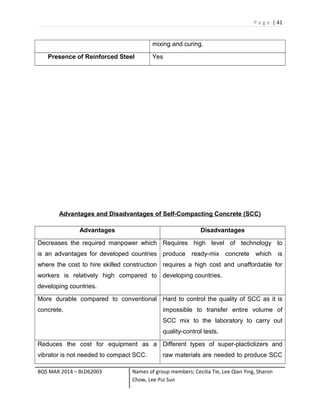

The document provides an overview of different types of concrete and their applications. It discusses autoclaved aerated concrete (AAC), its history, composition, manufacturing process, properties and applications. AAC is a lightweight, insulating building material made from cement, sand and an aluminum compound. It is used in wall, floor and roof construction. The document also covers asphalt concrete, decorative concrete, roller-compacted concrete and self-compacting concrete, outlining their histories, compositions, manufacturing processes and properties. The various types of concrete discussed each have advantages for different construction applications.