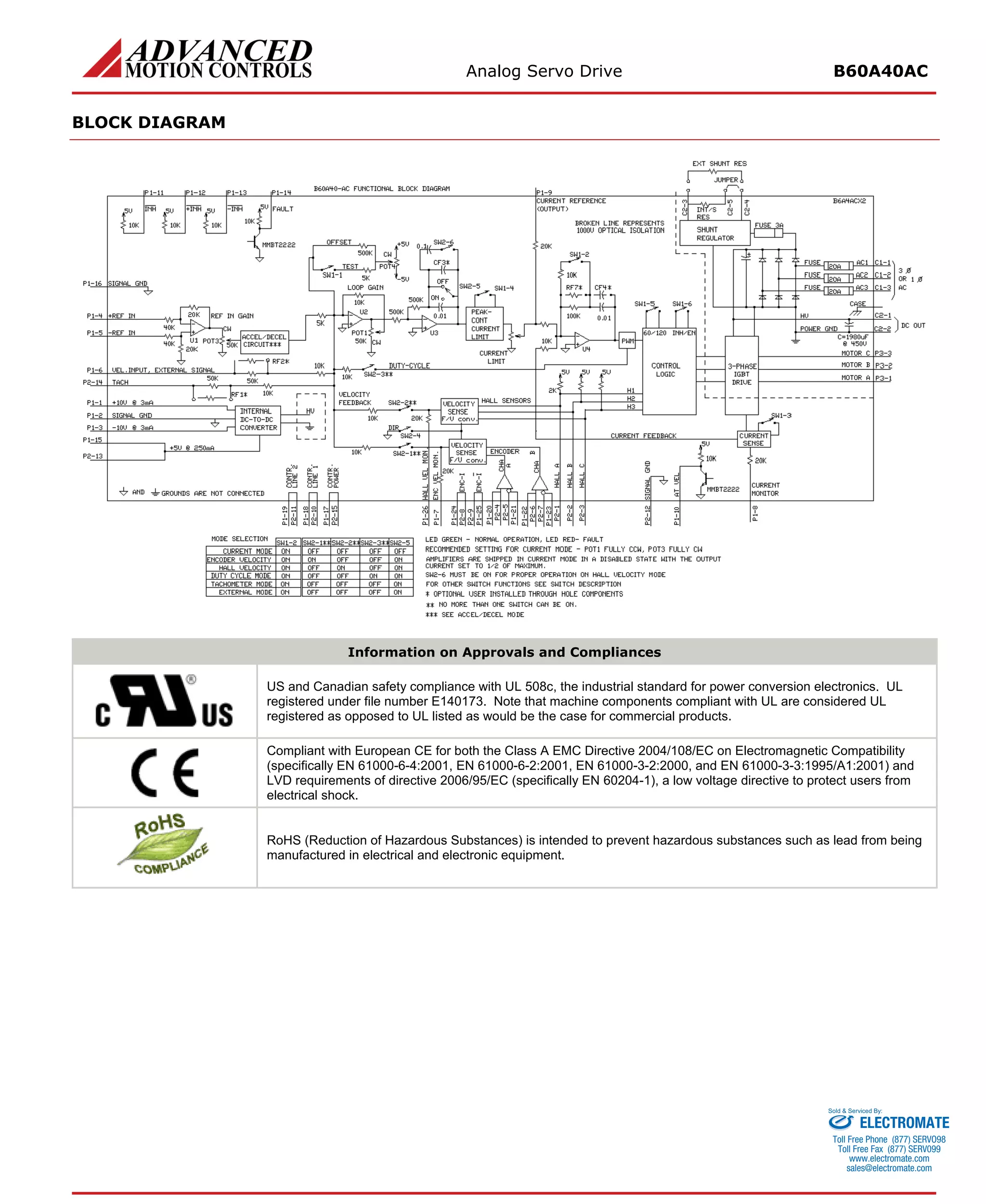

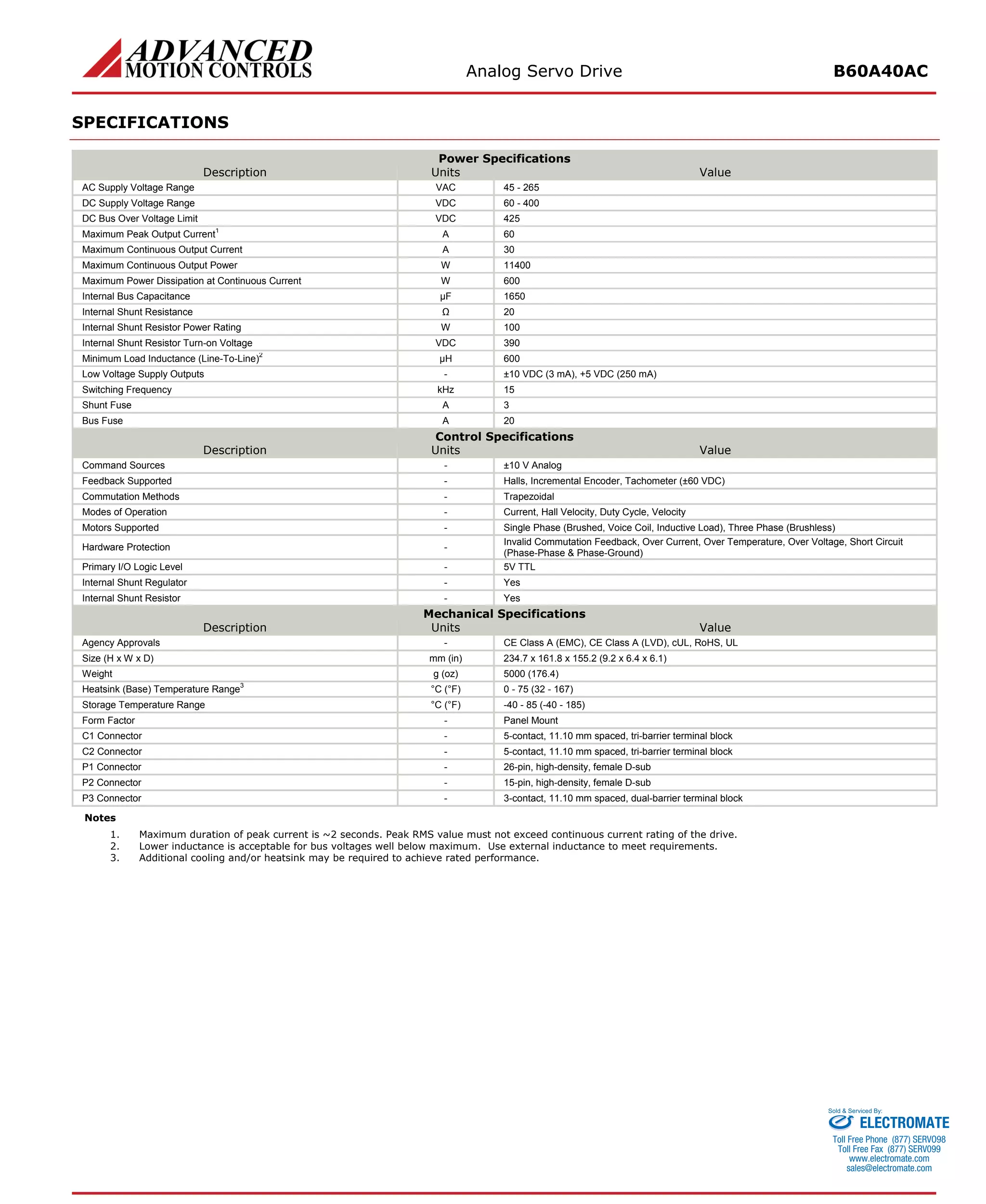

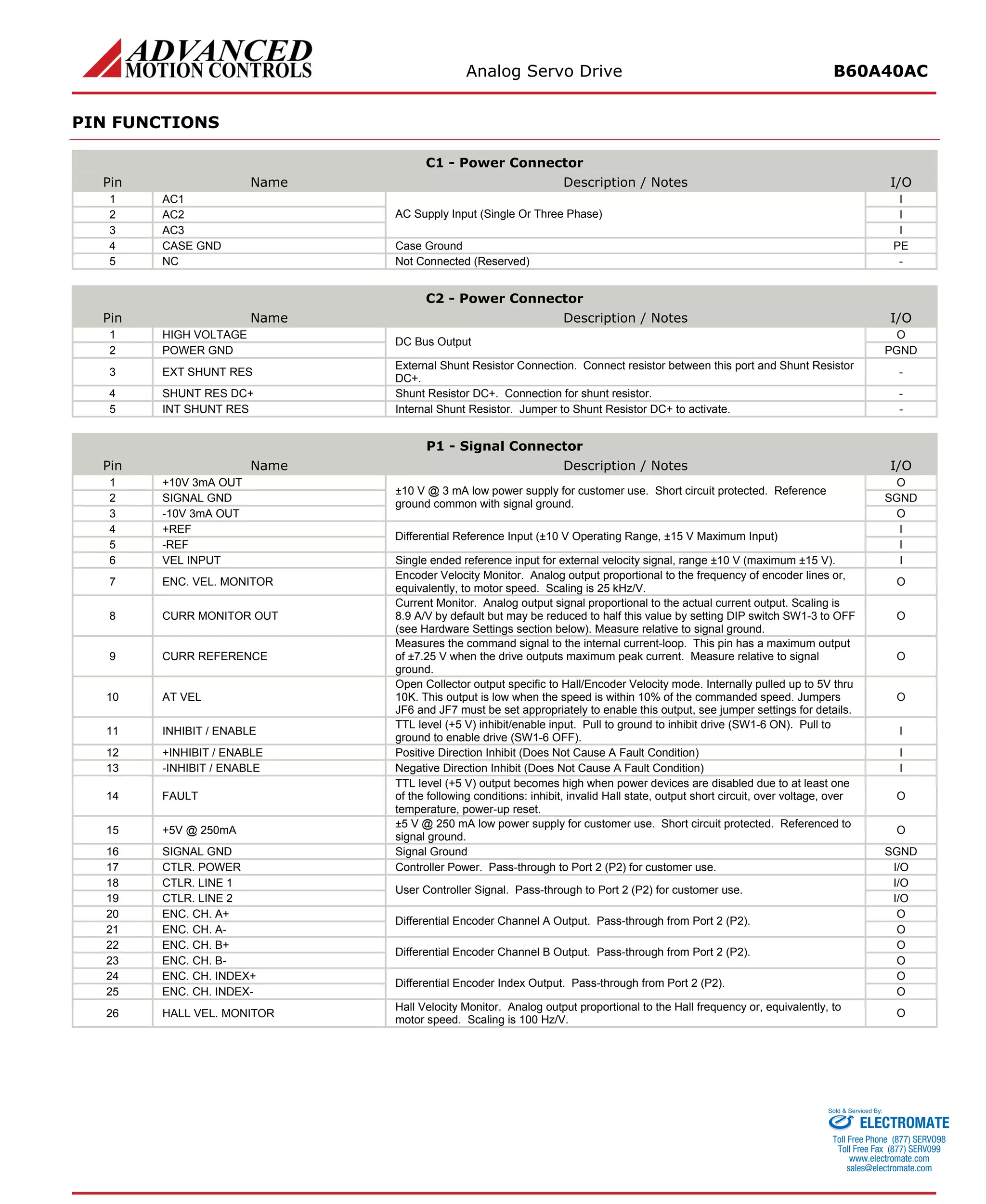

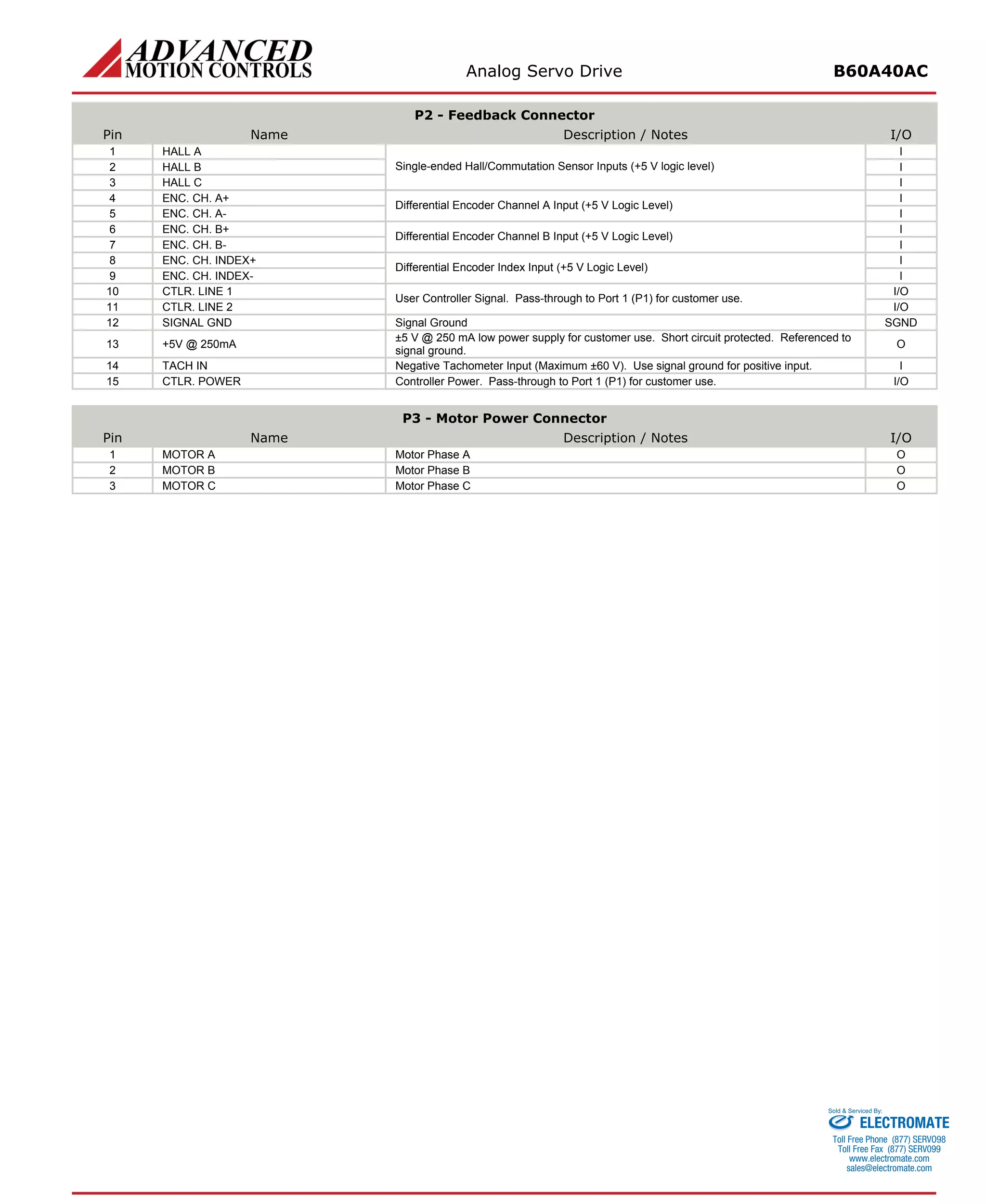

The document describes an analog servo drive that:

- Can provide up to 60A of peak current and 30A of continuous current from a 45-265VAC power supply.

- Includes protection against overvoltage, undervoltage, overcurrent and other faults.

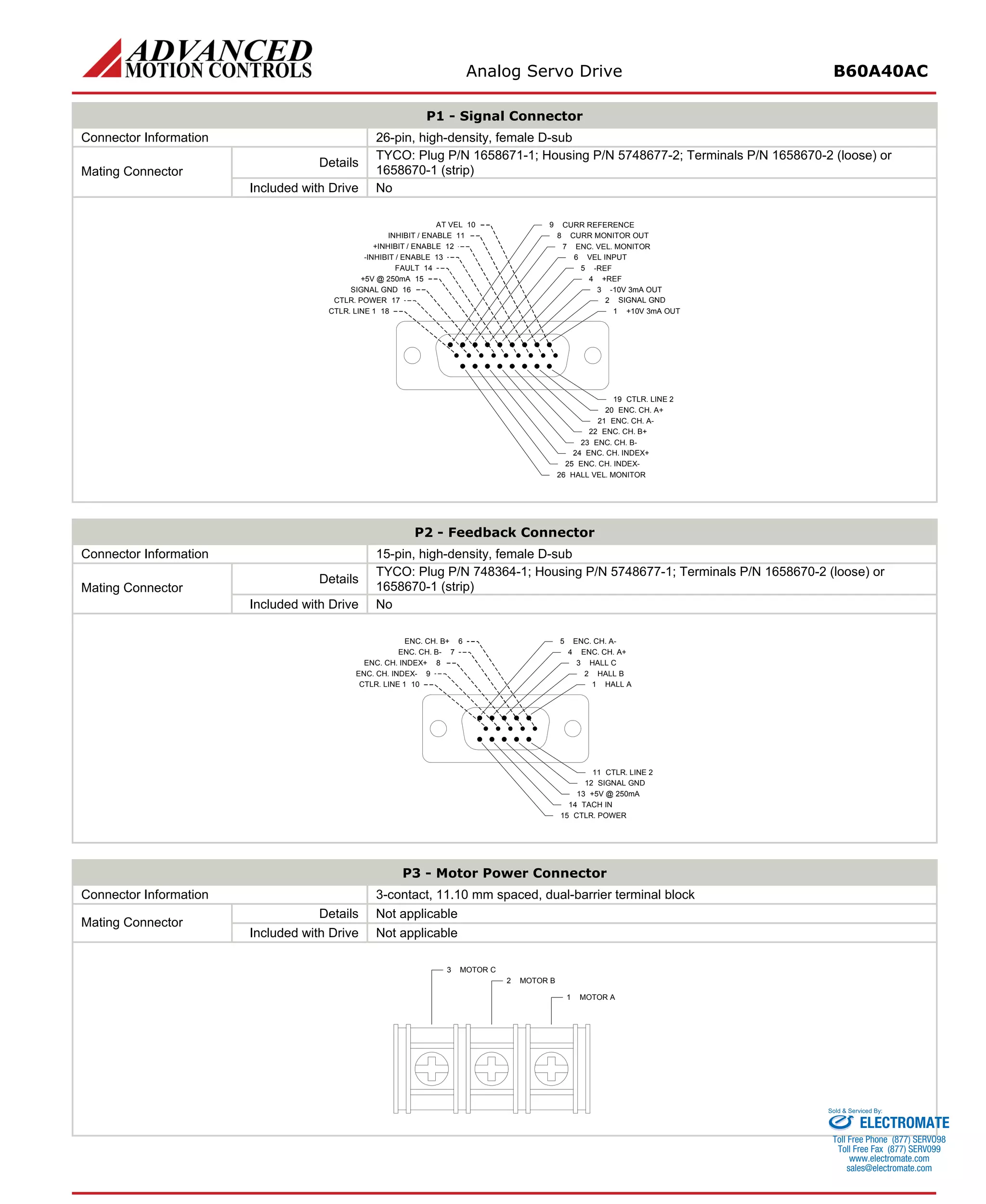

- Can be controlled via analog input or standalone and supports hall sensors, encoders or tachometers for feedback.

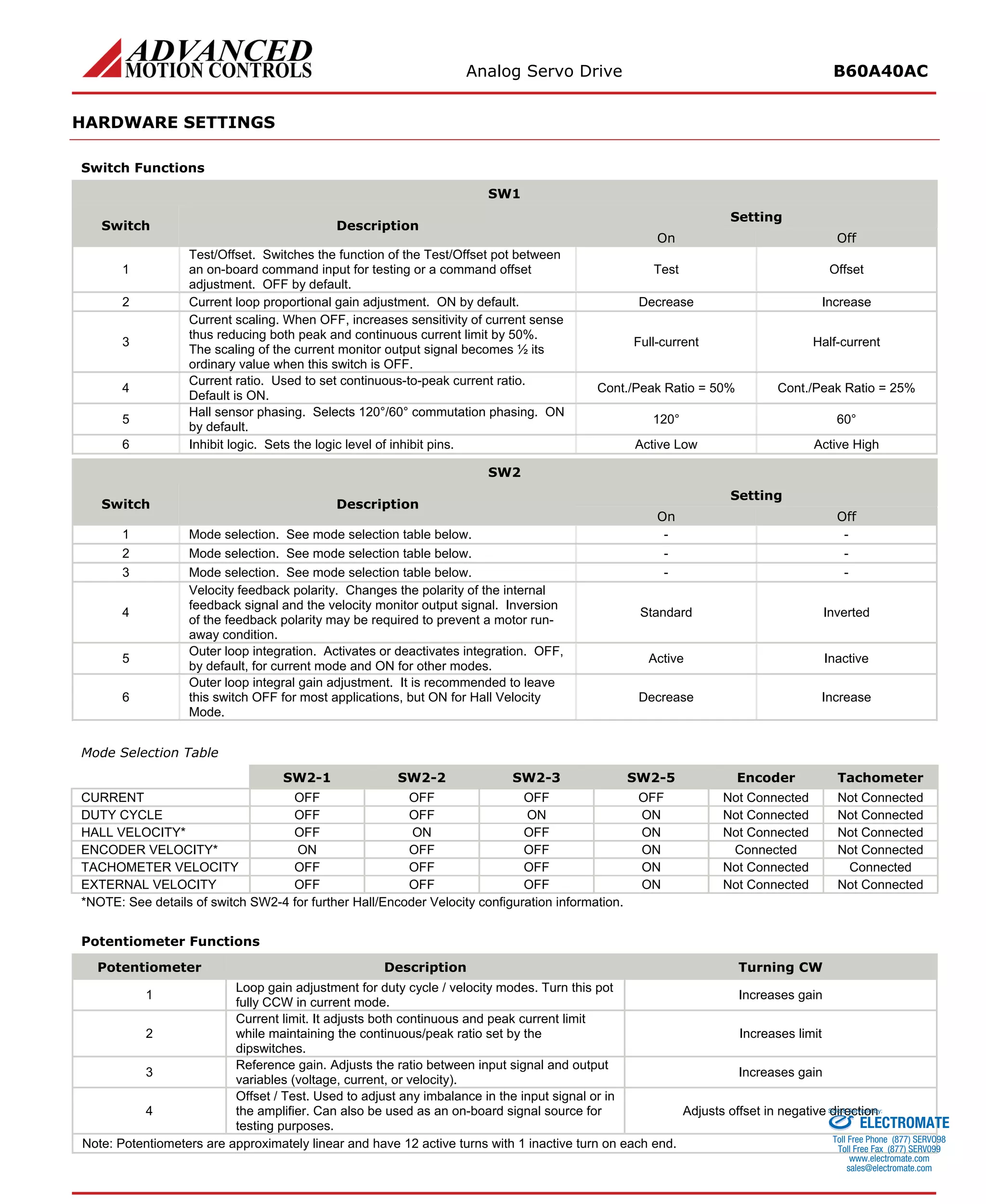

- Has adjustable parameters for current limit, gain and offset via potentiometers.