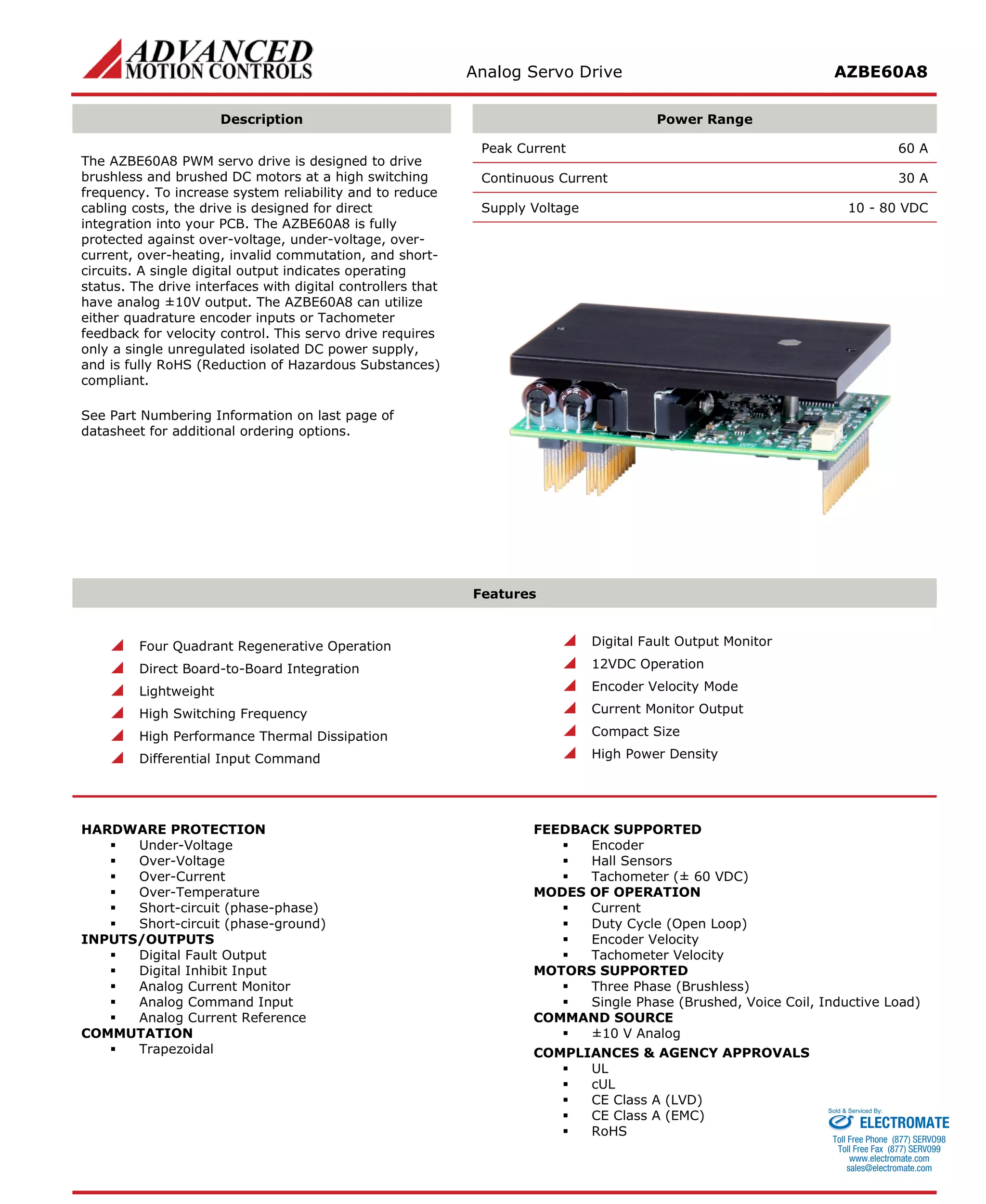

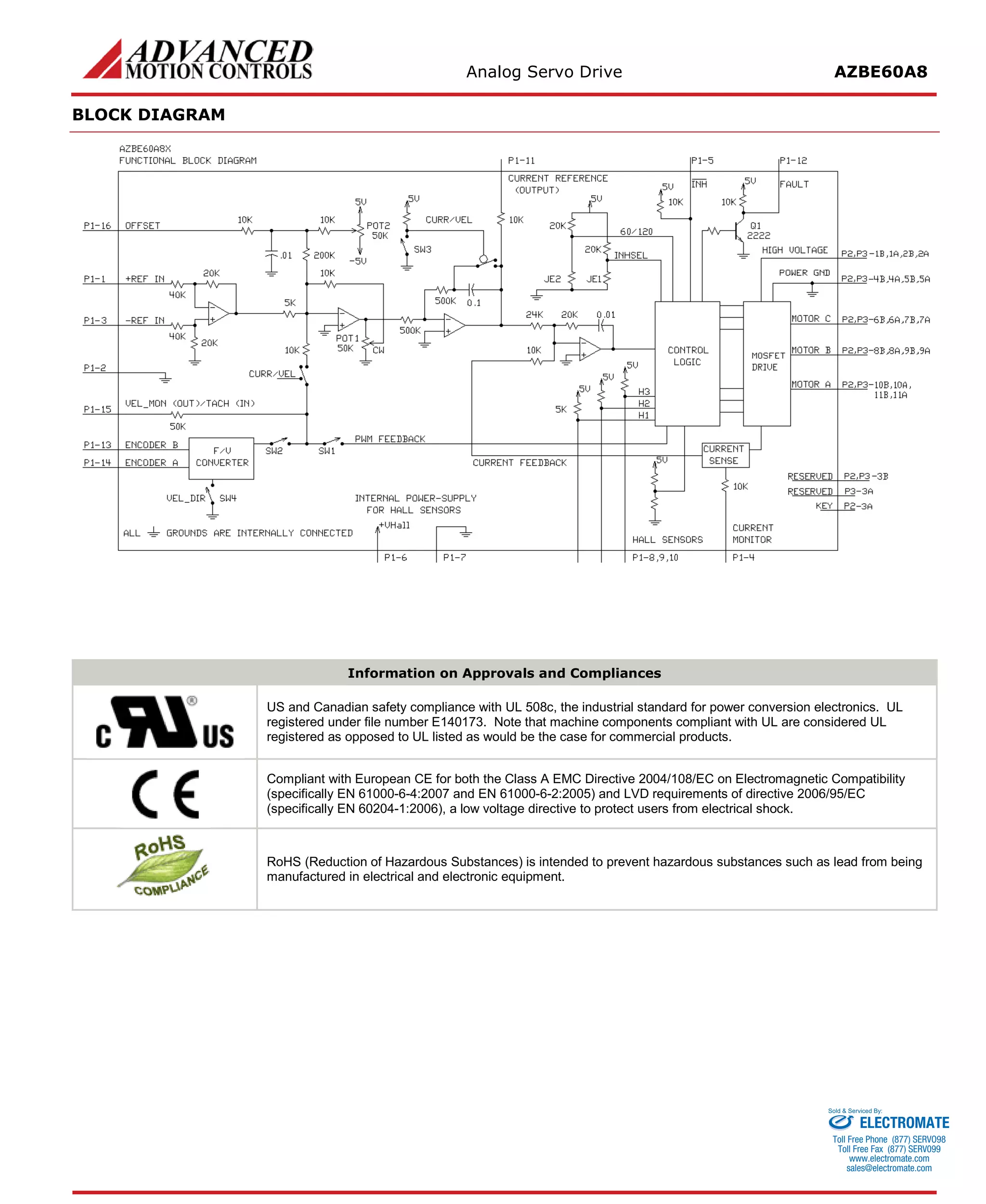

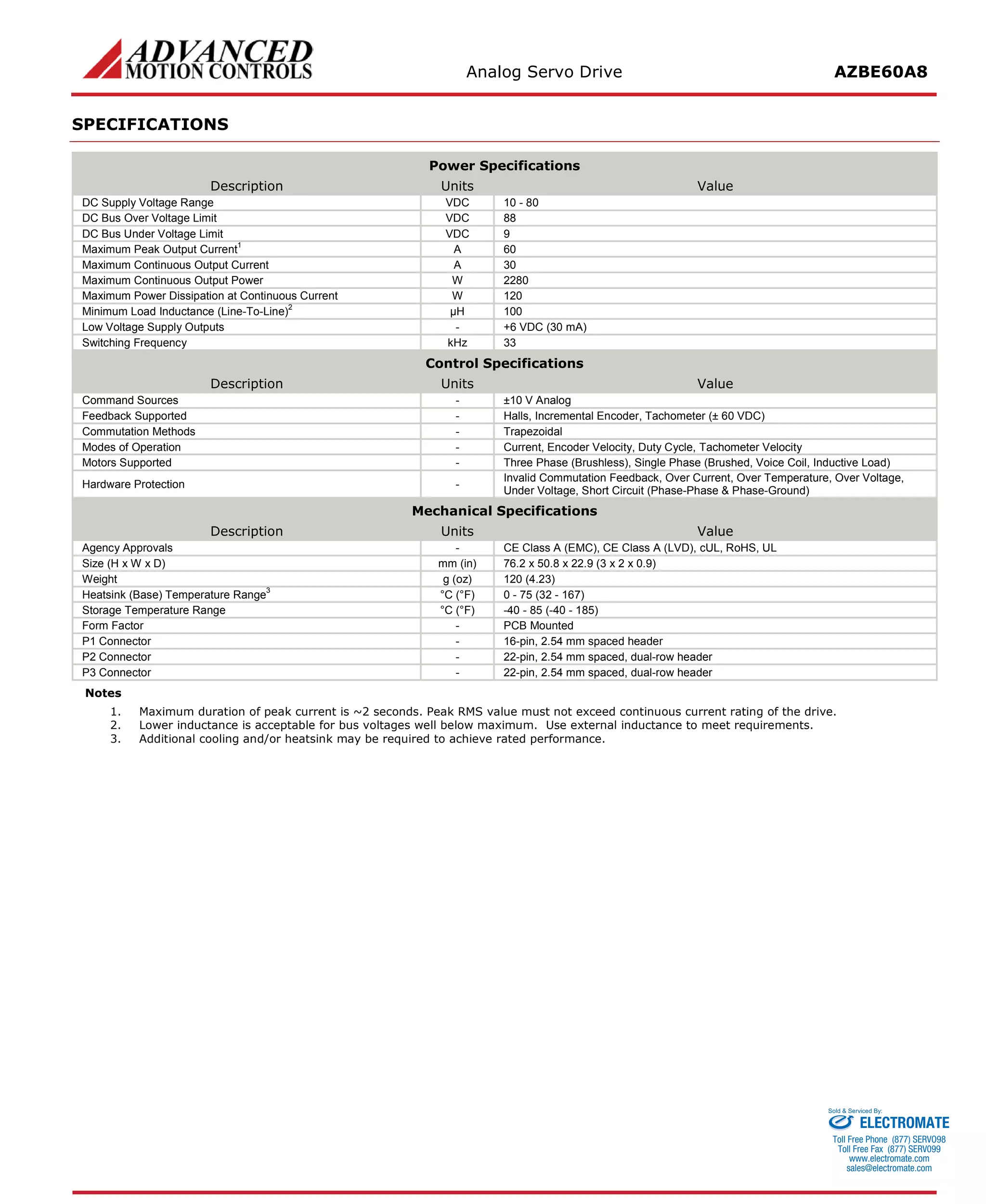

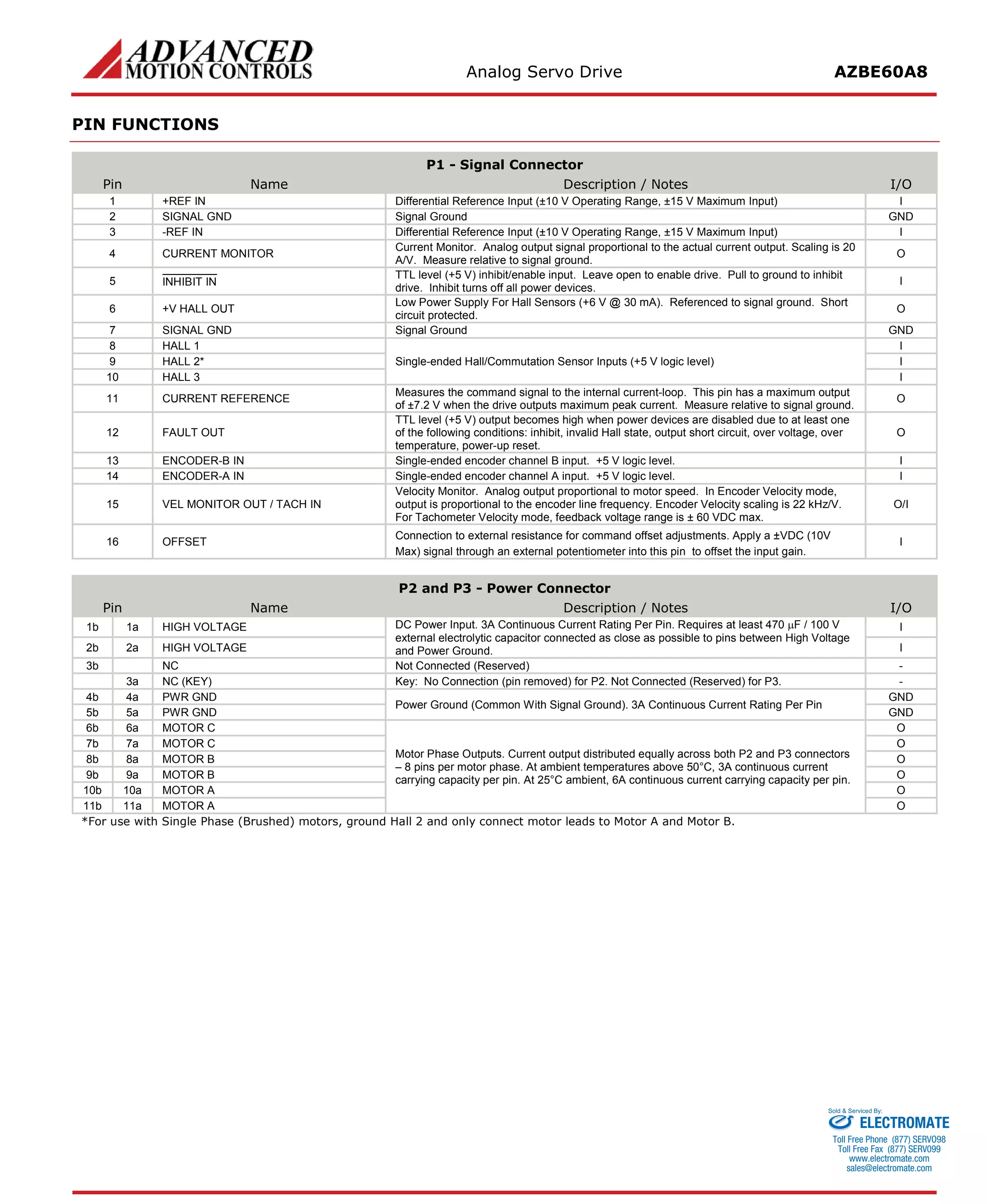

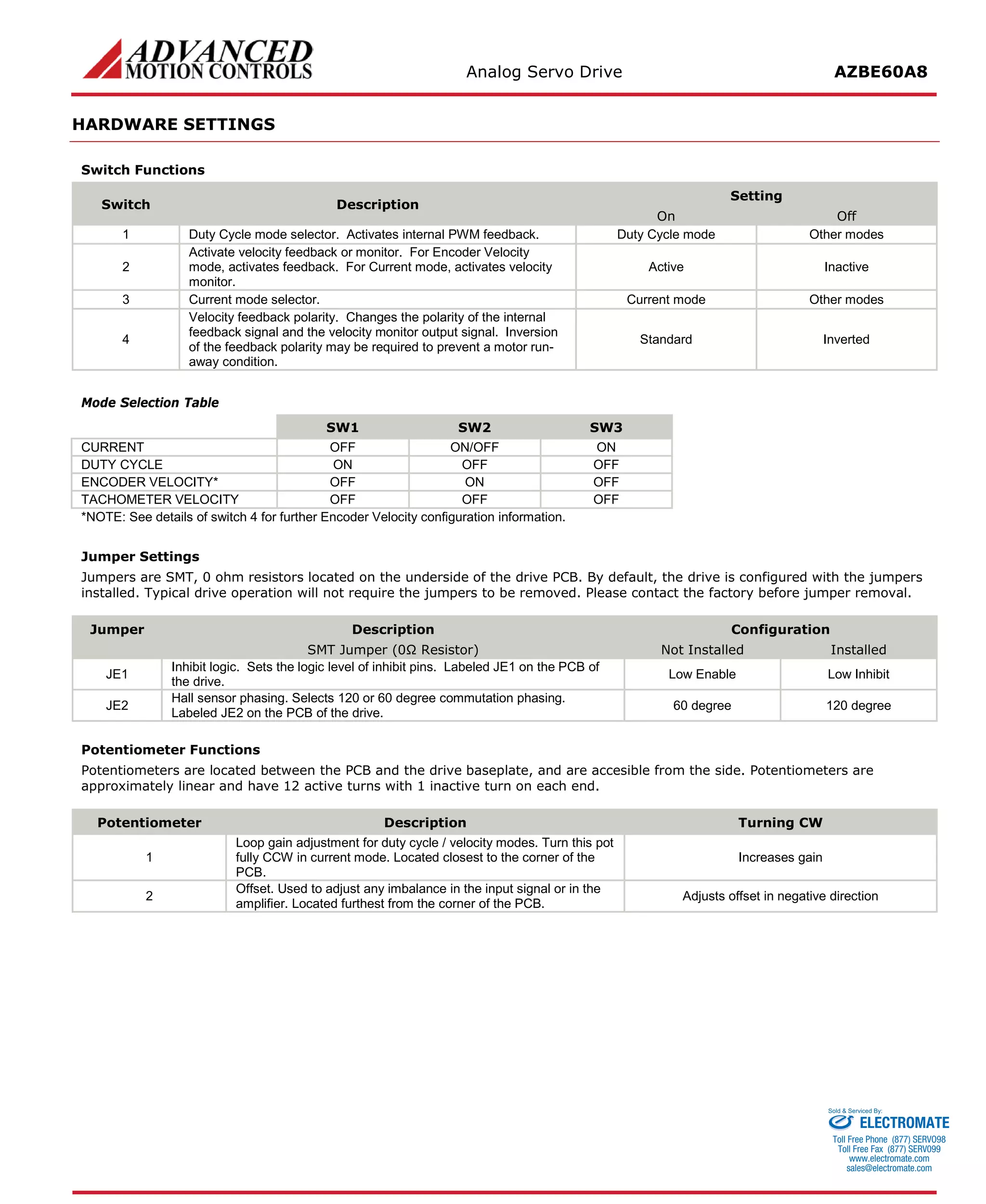

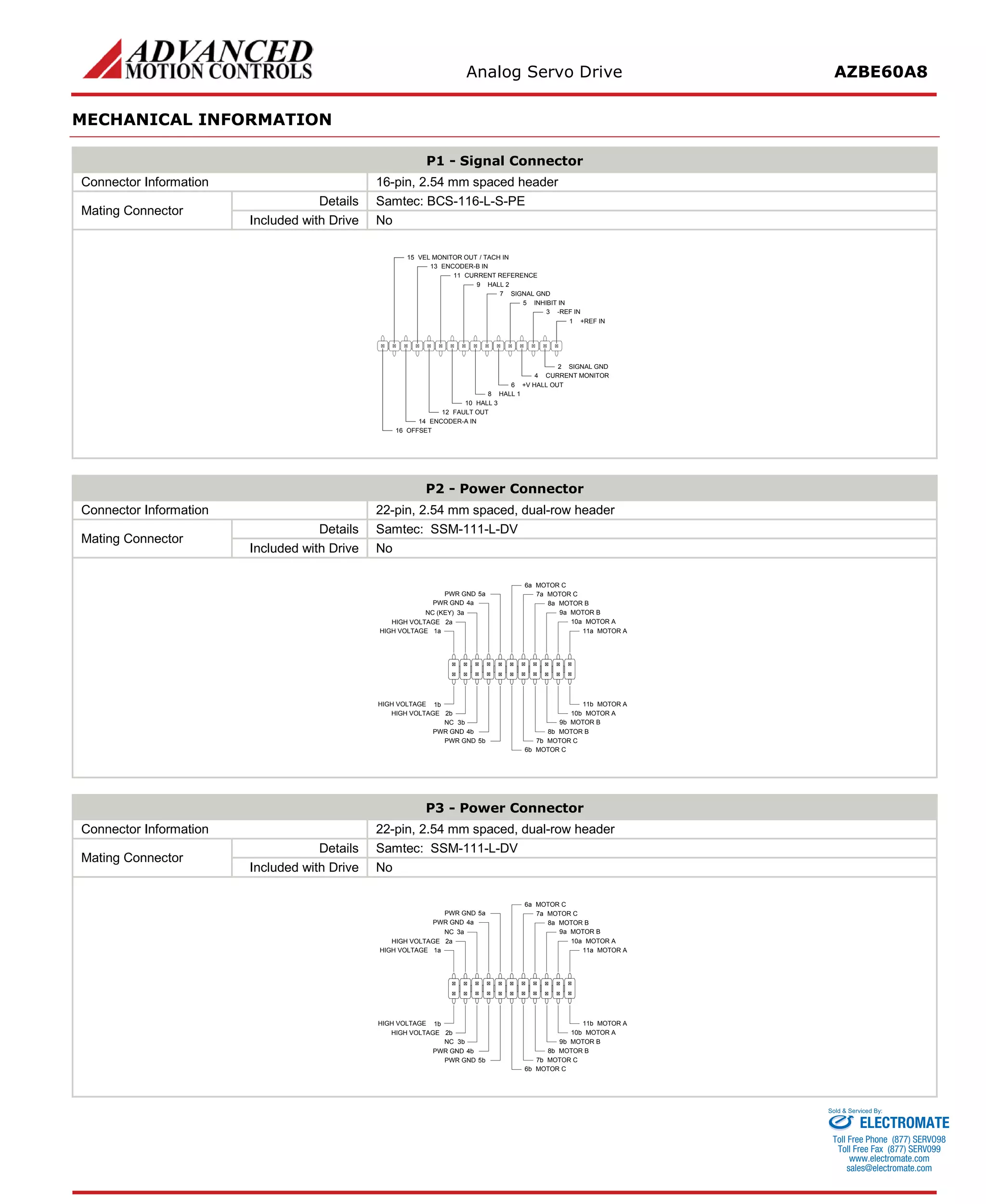

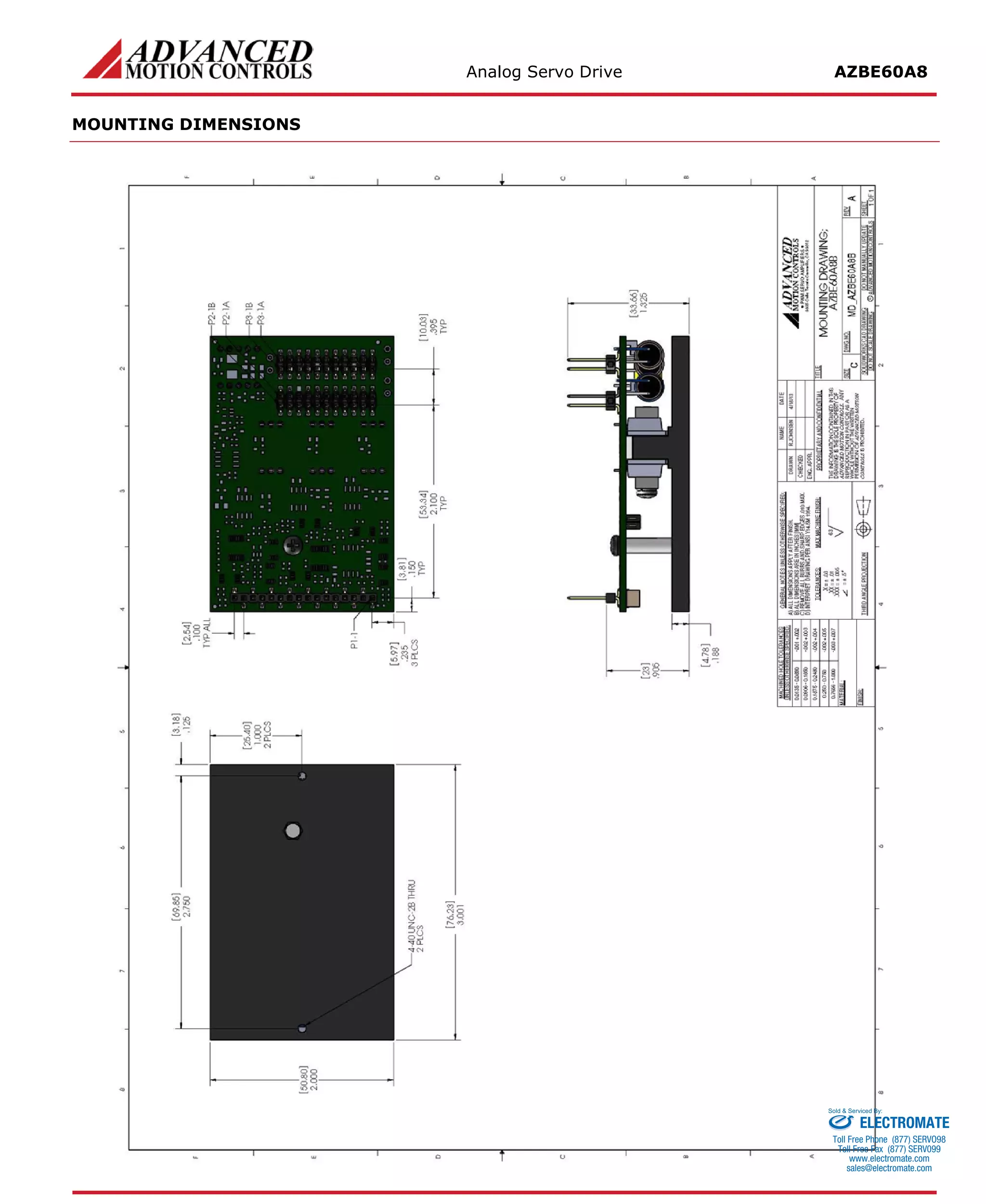

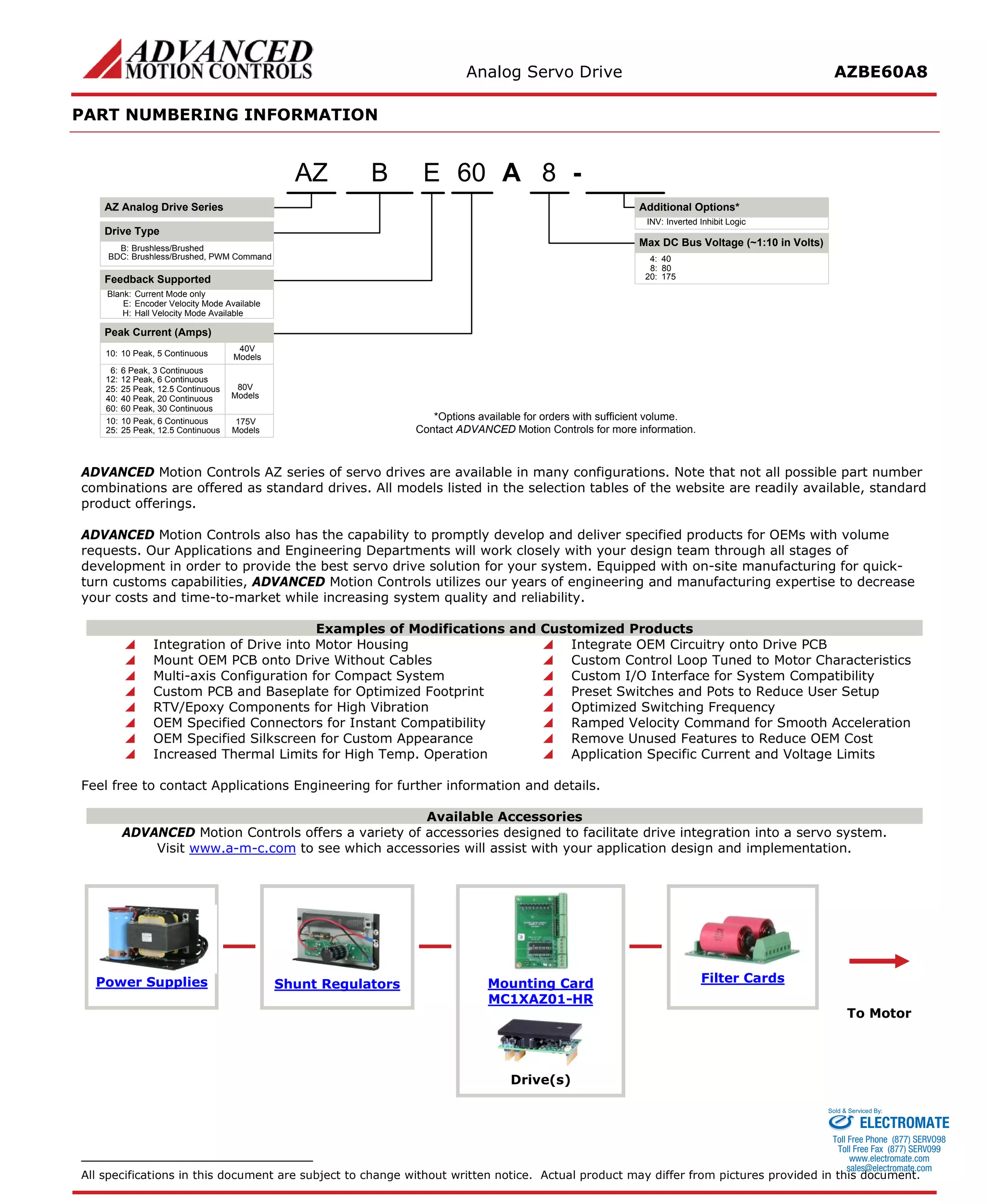

The document describes an analog servo drive called the AZBE60A8. It is designed to drive brushless and brushed DC motors at high switching frequencies. Key specifications include a peak current of 60A, continuous current of 30A, and operating voltage range of 10-80VDC. It has protection against overvoltage, undervoltage, overcurrent and more. It can utilize encoder, hall sensor, or tachometer feedback and supports various motor and operation modes.