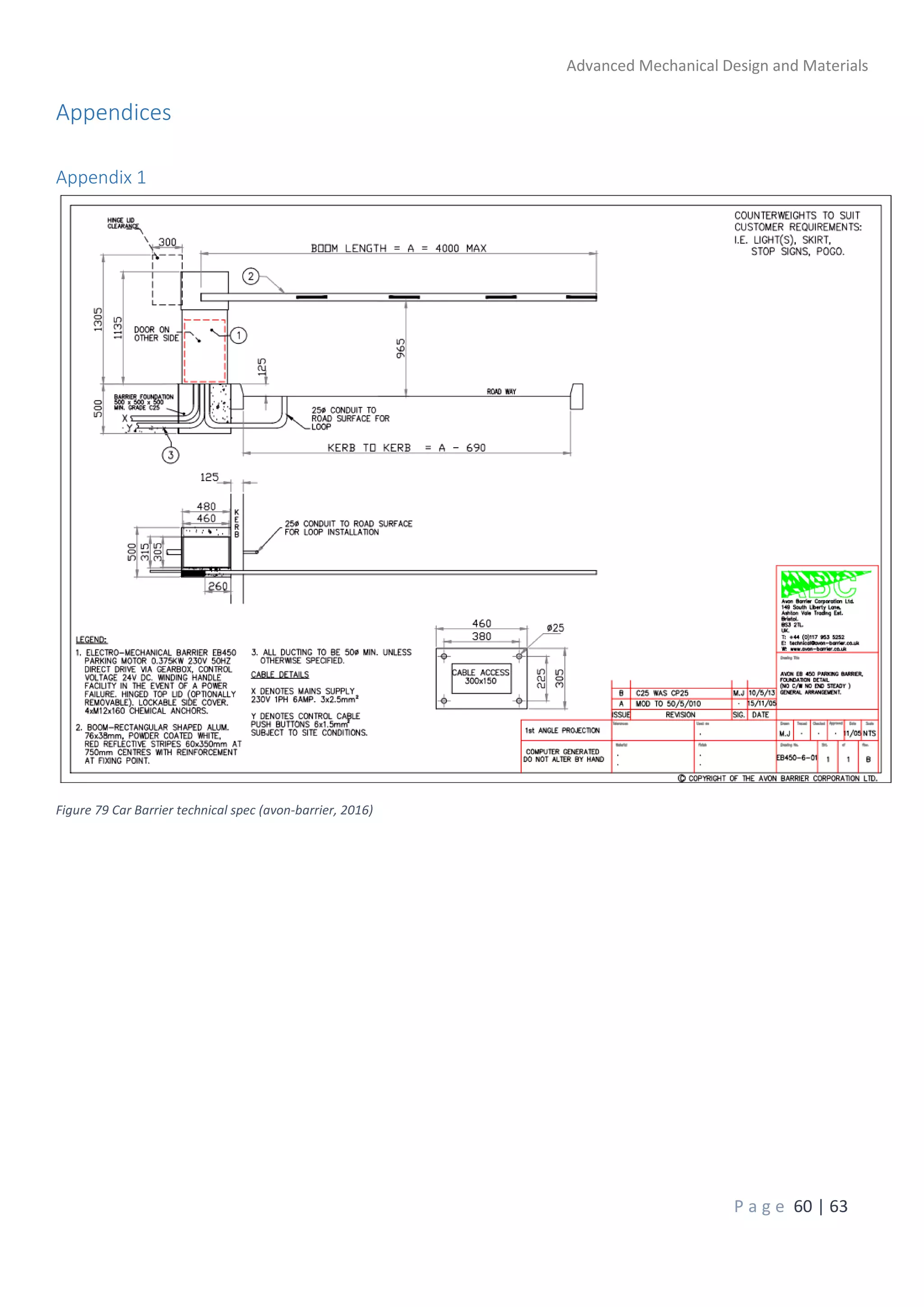

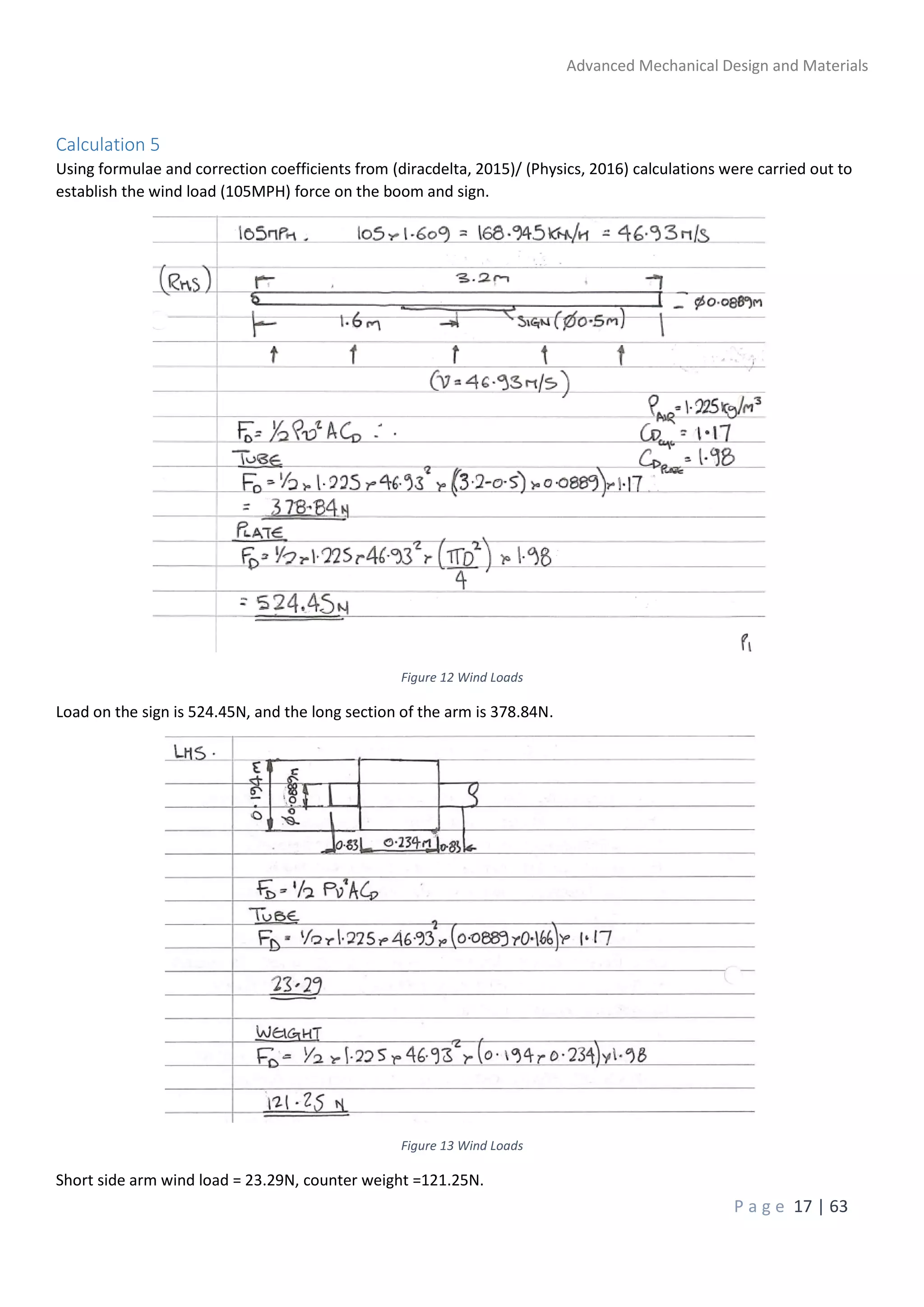

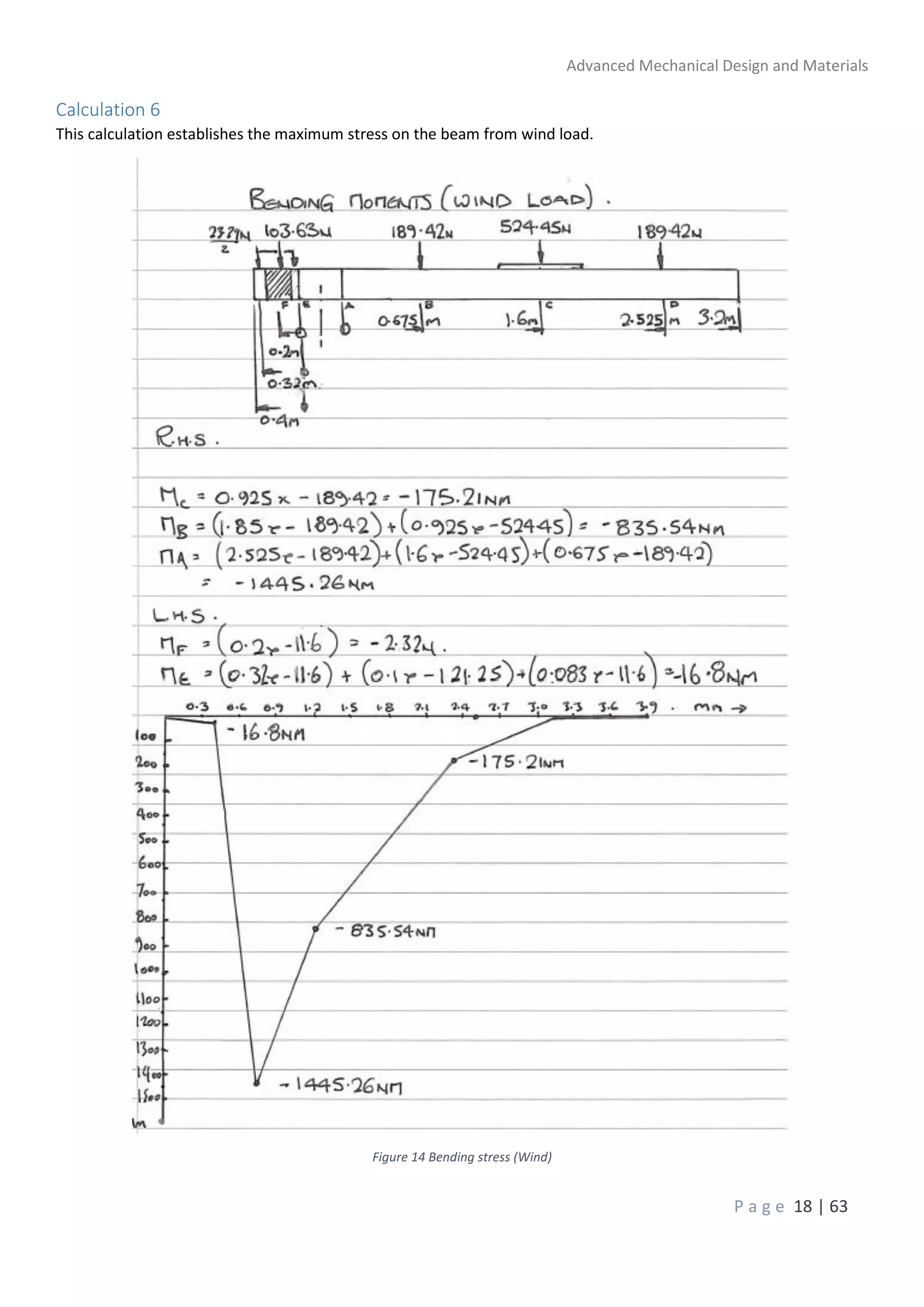

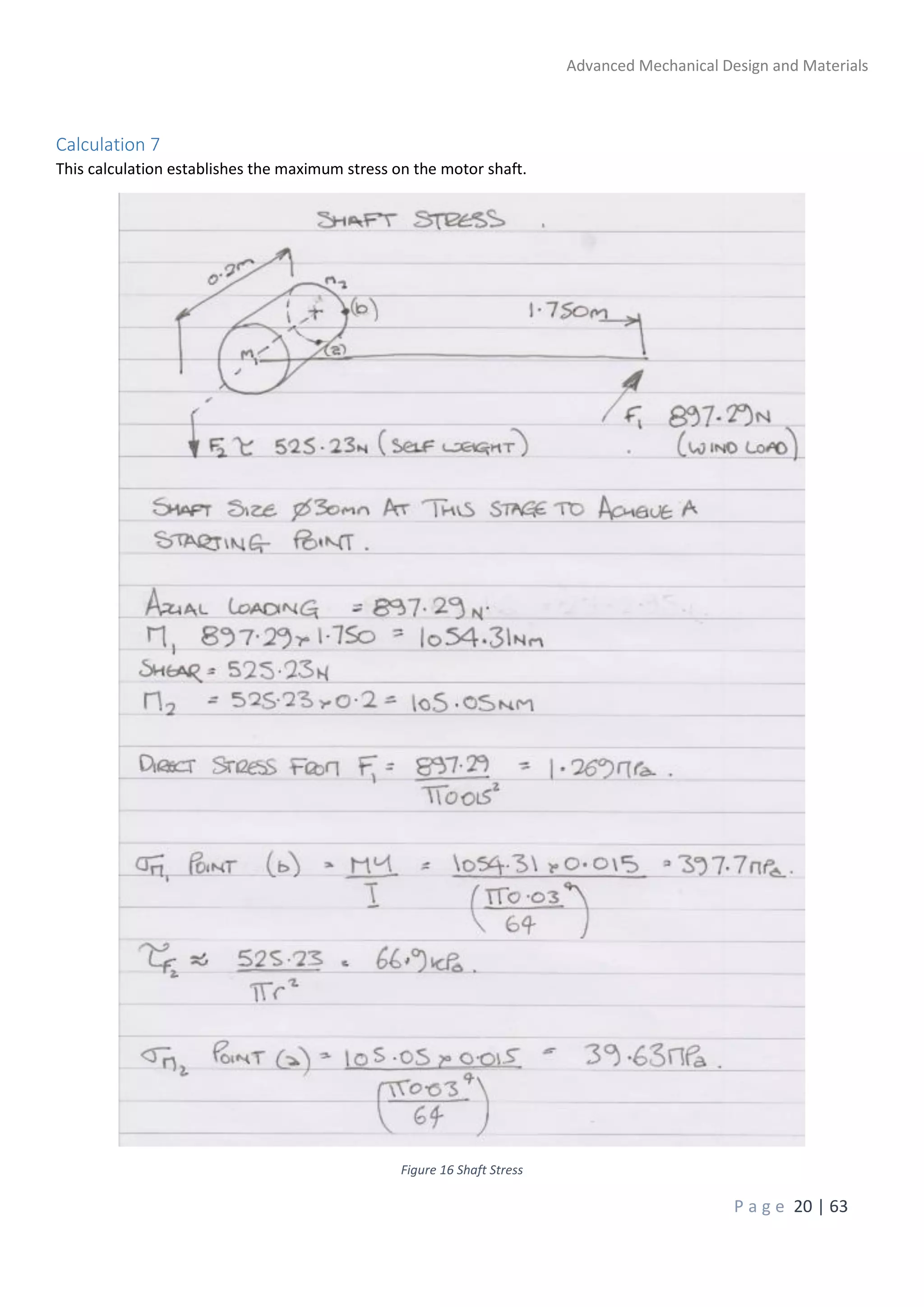

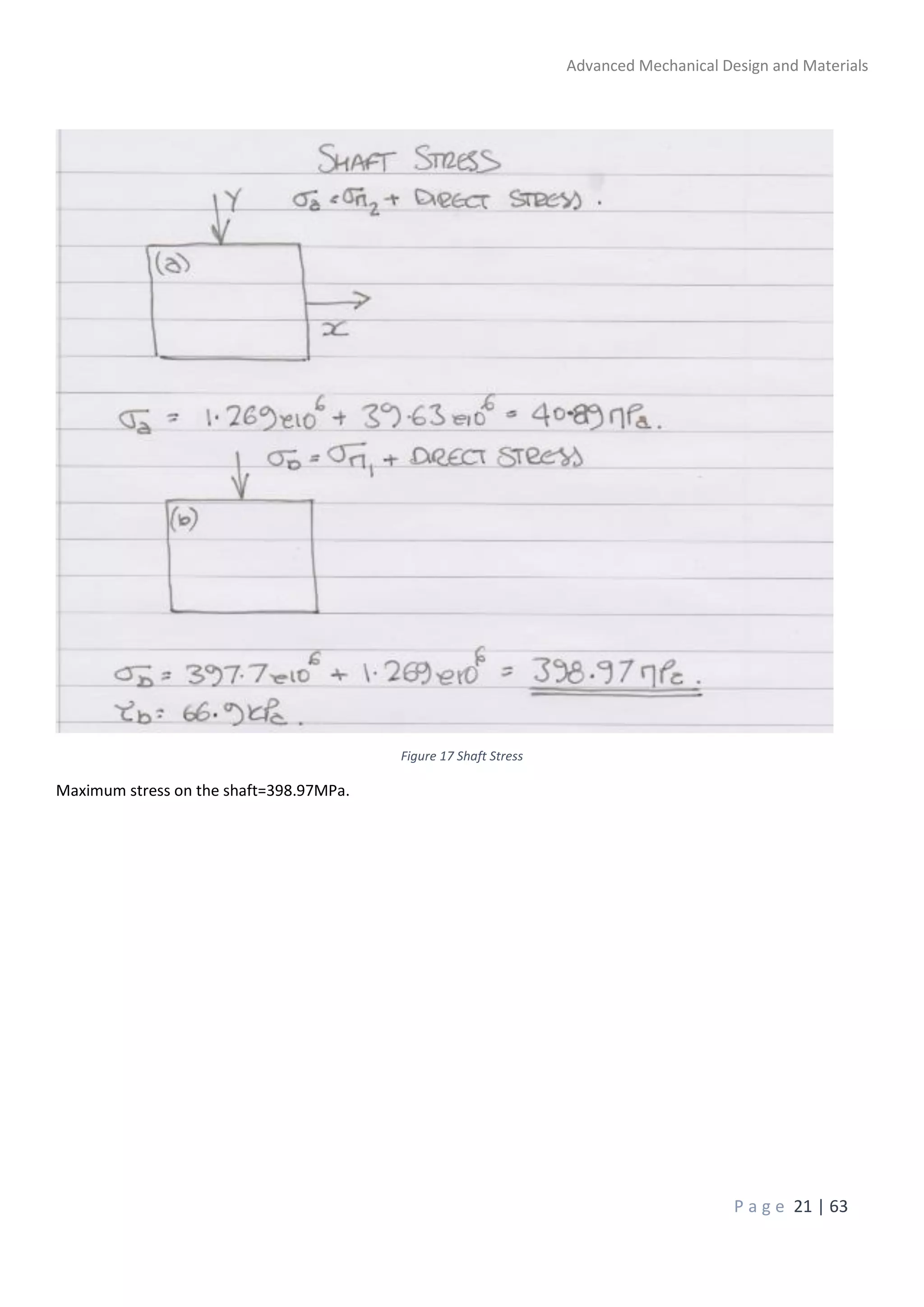

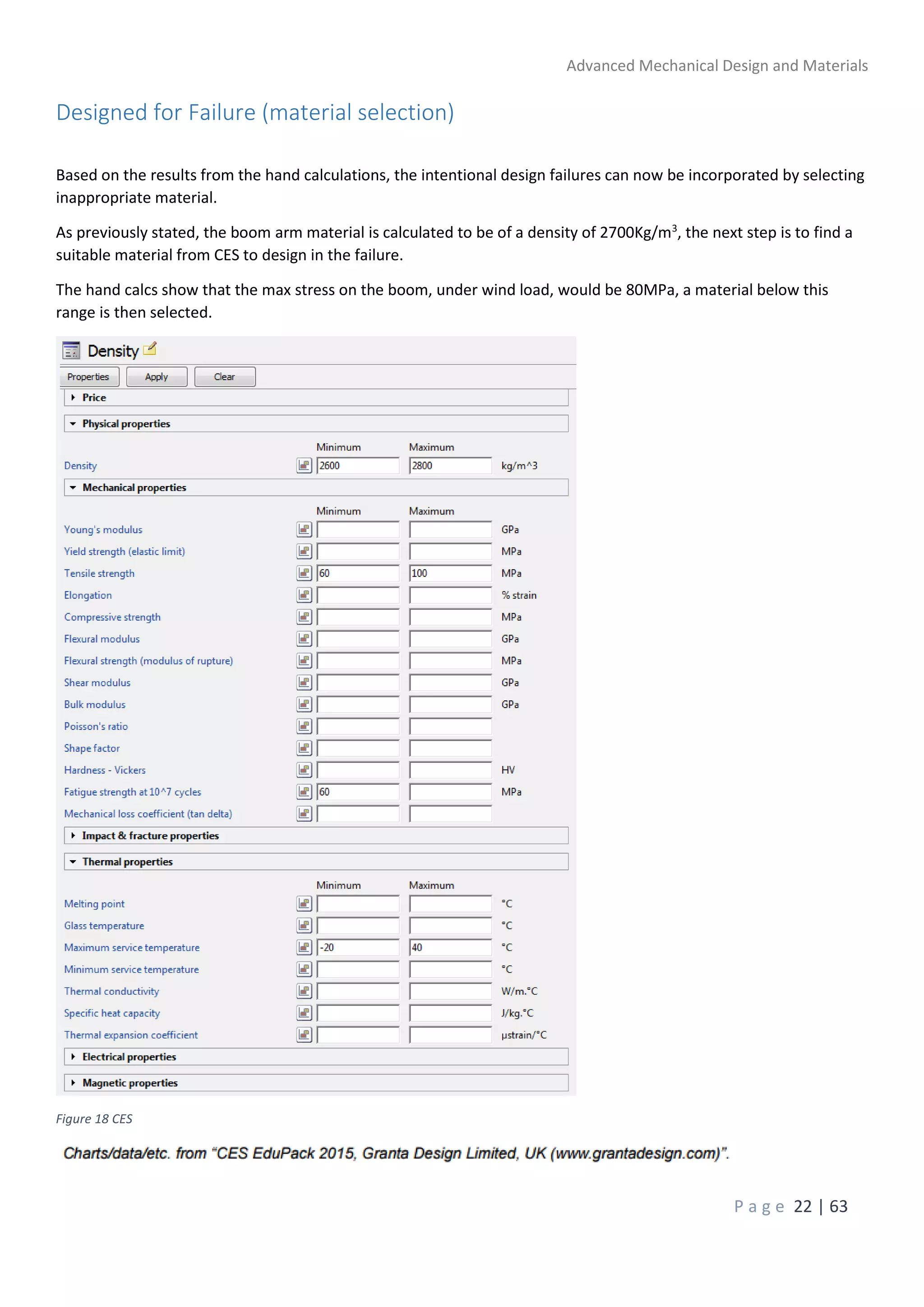

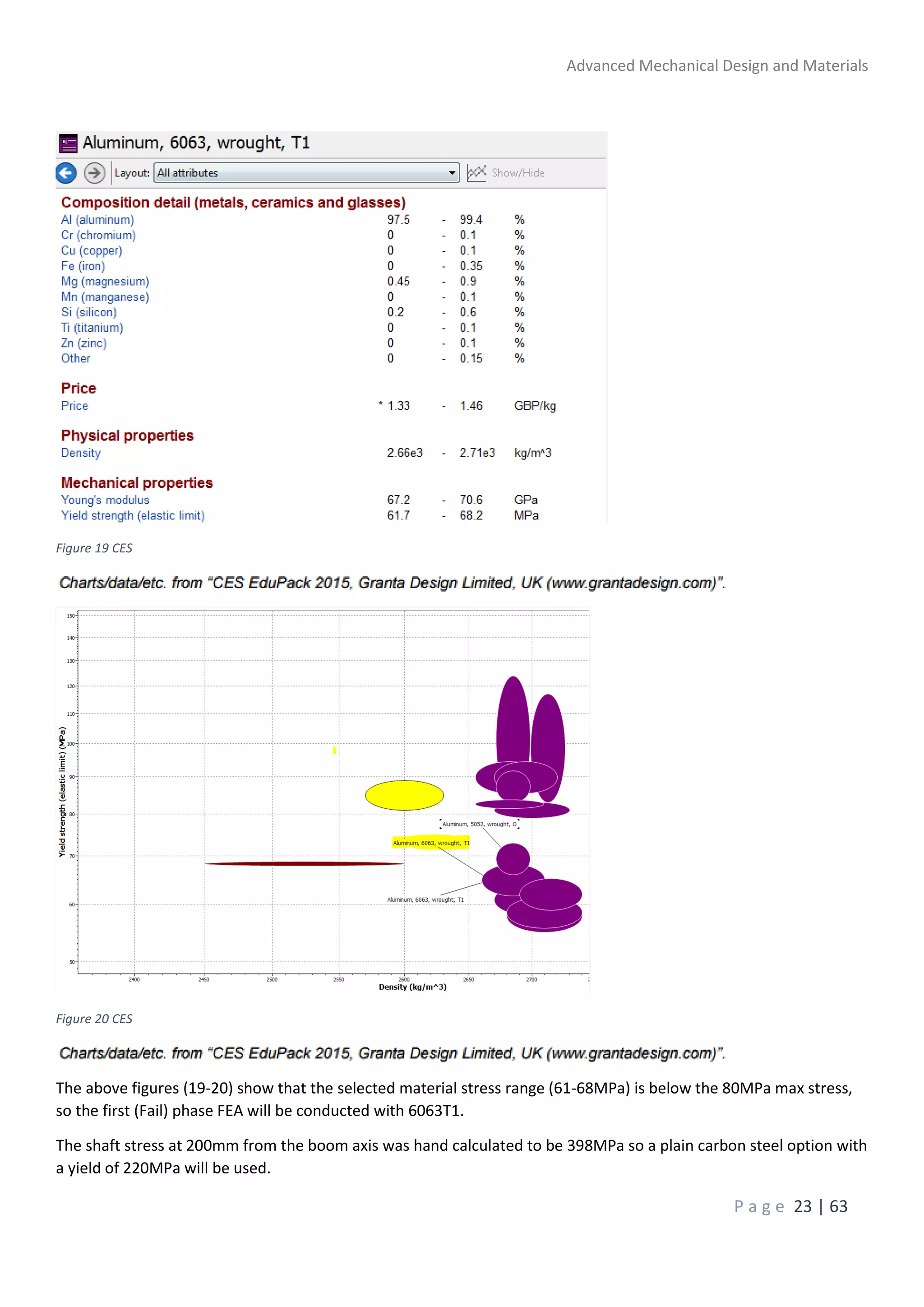

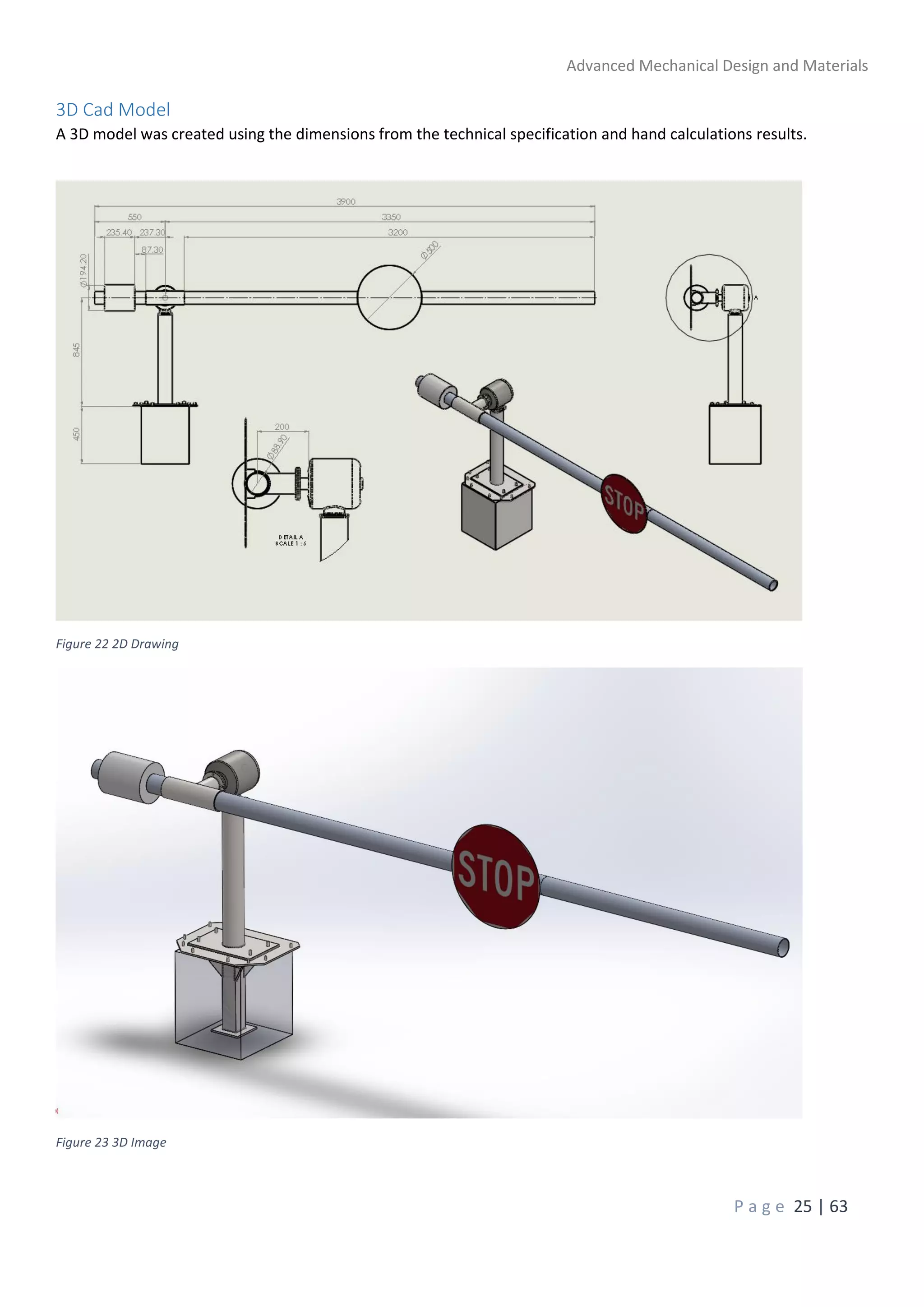

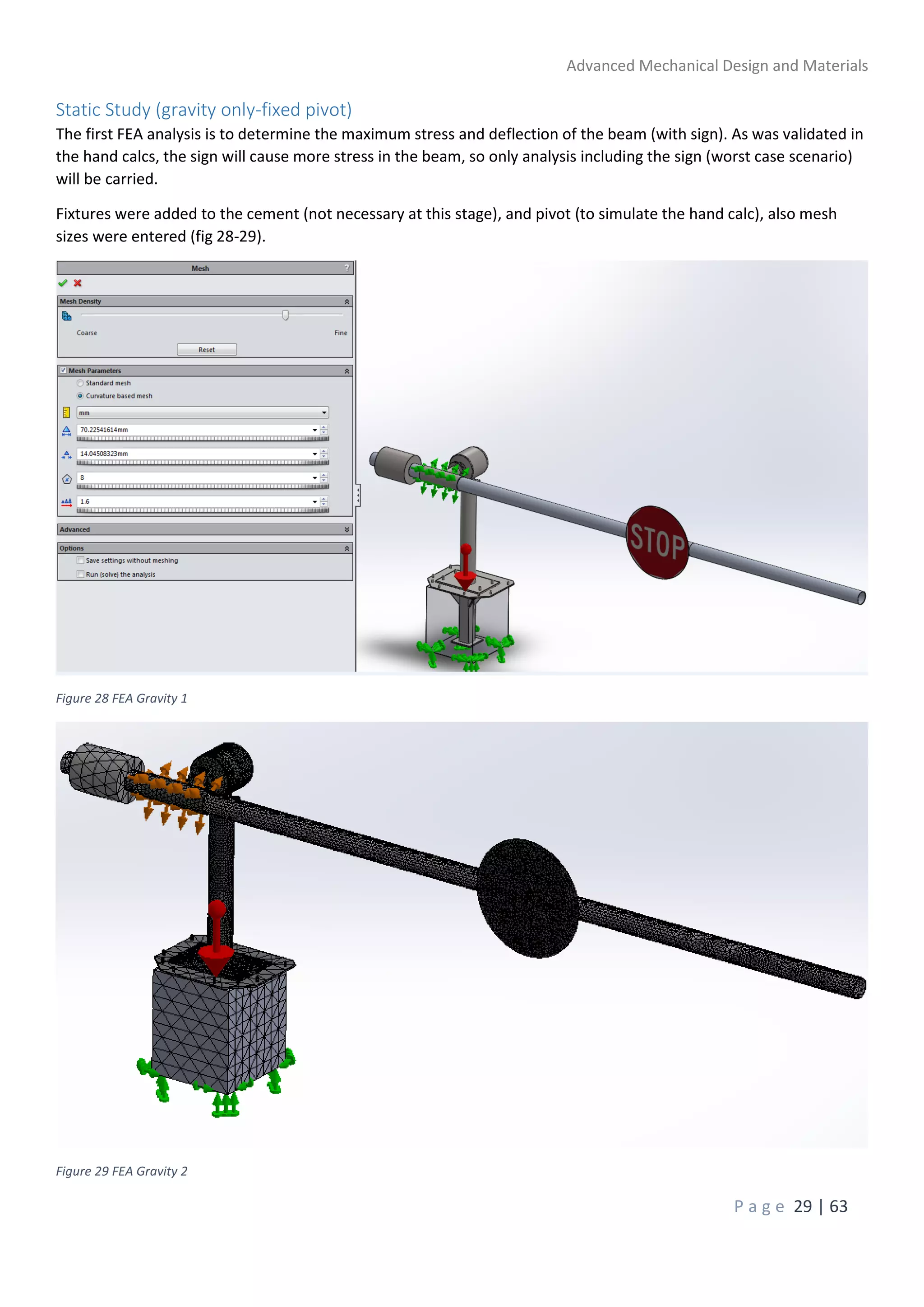

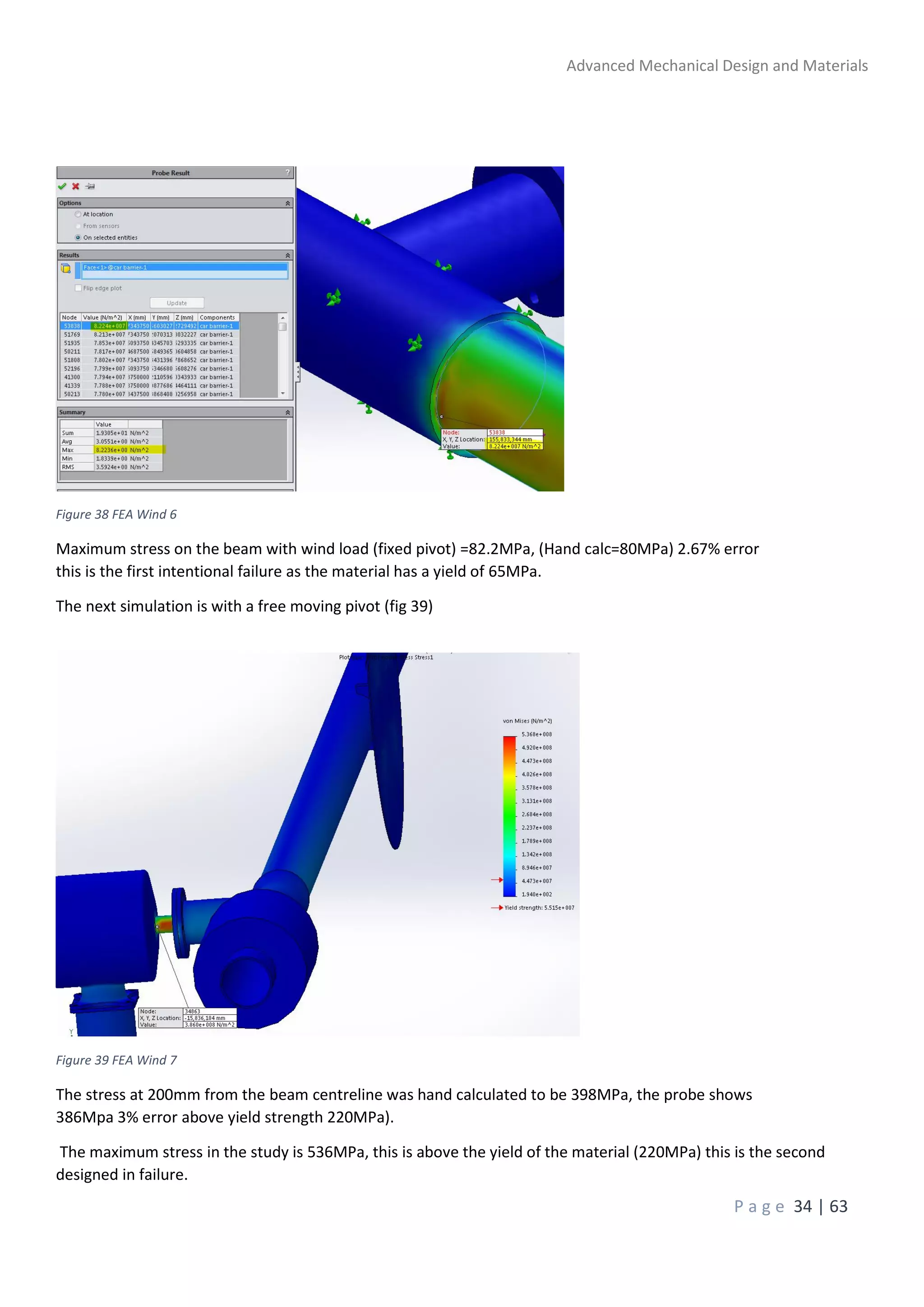

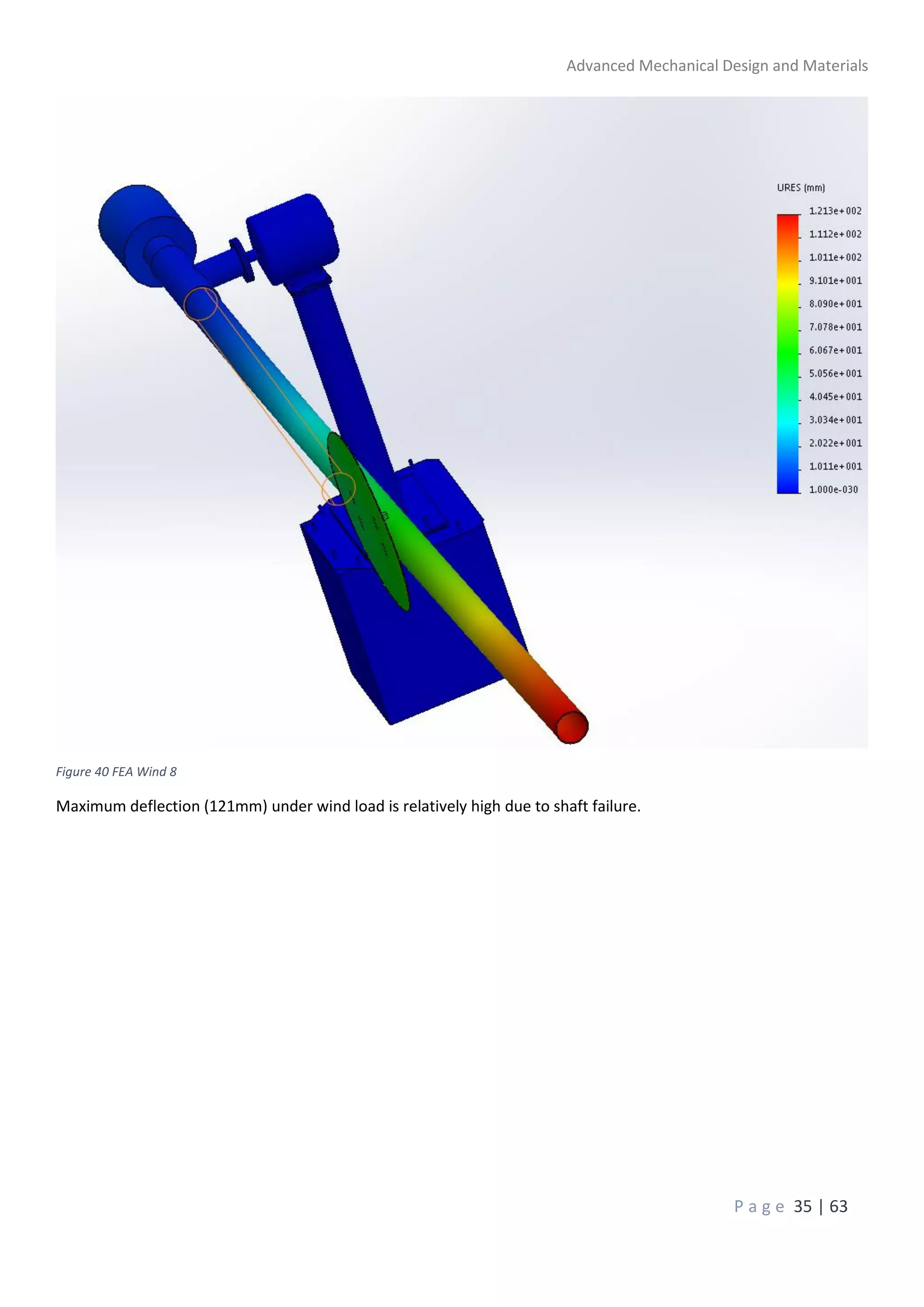

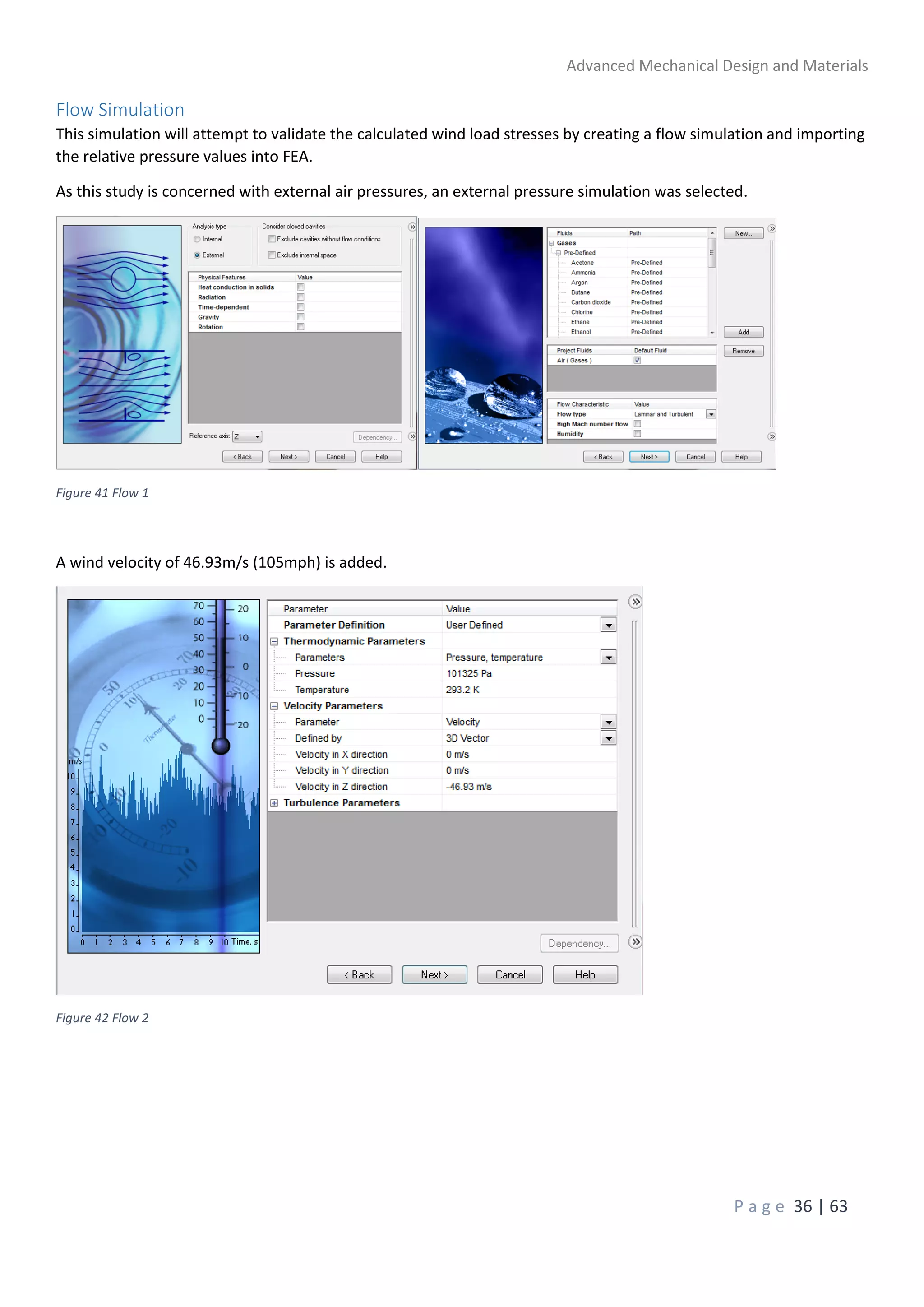

A design for a car park barrier was created using Solidworks to withstand wind speeds up to 105MPH and have an actuation cycle life of over 107 cycles. Initial hand calculations determined stresses from self-weight and wind loads. These identified maximum stresses of 80MPa for the boom arm and 398MPa for the motor shaft. An intentionally weak material was selected to initially fail the design. Subsequent FEA analysis and material selection iterations were performed to optimize the design, validating it could withstand the required loads with suitable safety factors.

![Advanced Mechanical Design and Materials

P a g e 58 | 63

References

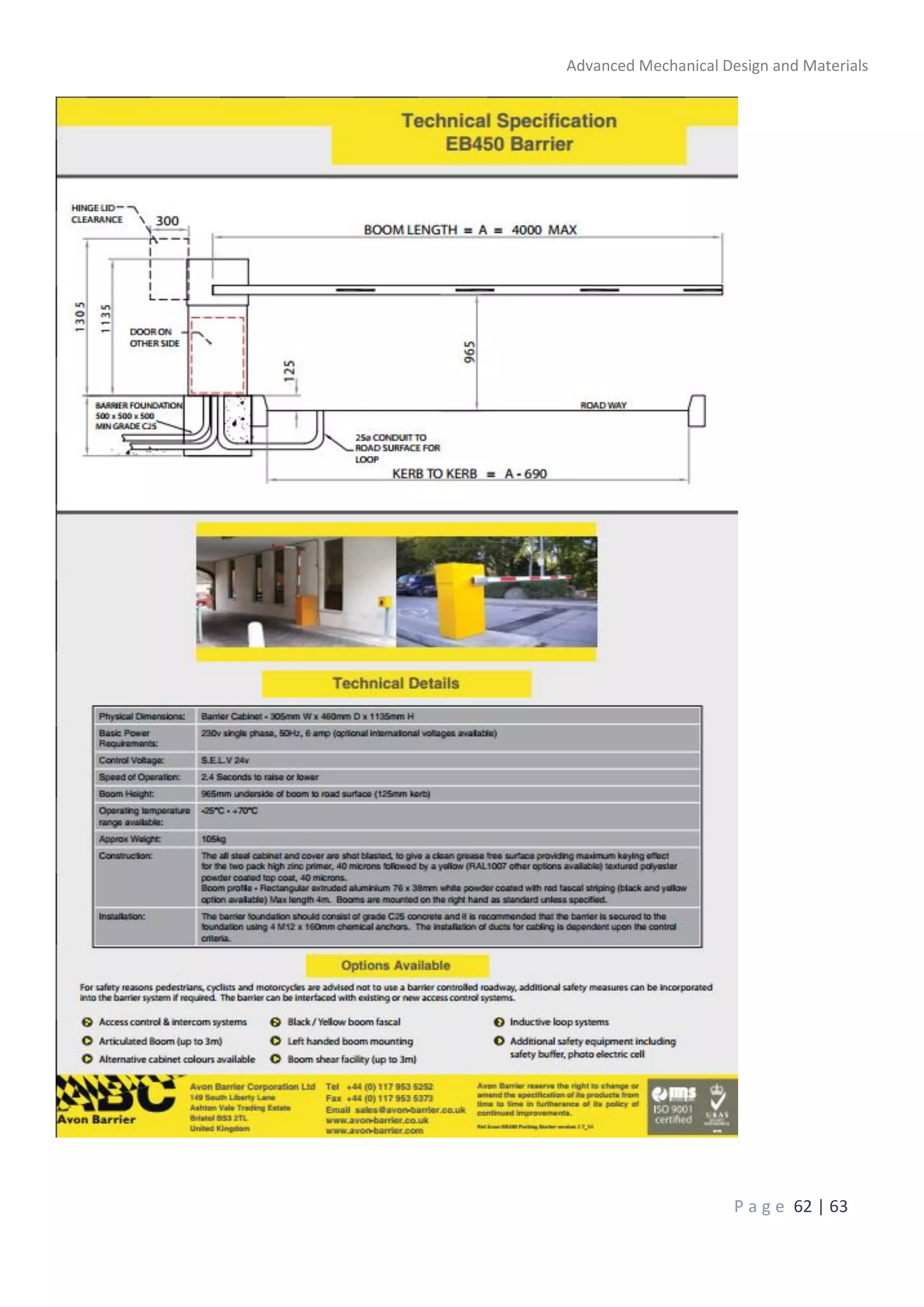

avon-barrier. (2016) Parking-Barriers. [Online]

Available at: http://www.avon-barrier.co.uk/Parking-Barriers-

(Accessed 21 4 2016)

b2bmetal. (2016) 144. [Online]

Available at: http://www.b2bmetal.eu/en/pages/index/index/id/144/

(Accessed 21 4 2016)

barriersdirec. (2016) arm-barriers. [Online]

Available at: http://www.barriersdirect.co.uk/barriers-c1157/arm-barriers-c1117/aluminium-manual-rising-arm-

barriers-up-to-7m-p8961

(Accessed 21 4 2016)

diracdelta. (2015) drag. [Online]

Available at: http://www.diracdelta.co.uk/science/source/d/r/drag%20coefficient/source.html#.VxjvAfkrKUl

(Accessed 2016 4 2016)

javelin-tech. (2016) solidworks-simulation-accuracy. [Online]

Available at: http://www.javelin-tech.com/blog/2015/01/solidworks-simulation-accuracy/

(Accessed 21 4 2016)

kloecknermetalsuk. (2015) Aluminium-Productsi. [Online]

Available at: http://www.kloecknermetalsuk.com/wp-content/uploads/2015/09/SA-5775-Aluminium-Productsi1.pdf

(Accessed 21 4 2016)

materion. (2014) Ratios. [Online]

Available at:

http://materion.com/~/media/Files/PDFs/Alloy/Newsletters/Technical%20Tidbits/Issue%20No%2053%20-

%20Fatigue%20and%20Stress%20Ratios.pdf

(Accessed 21 4 2016)

metoffice. (21/4/2016) wind-map. [Online]

Available at: http://www.metoffice.gov.uk/renewables/wind-map

(Accessed 21 04 2016)

metoffice. (2016) storm-katie. [Online]

Available at: http://www.metoffice.gov.uk/news/releases/2016/storm-katie

(Accessed 21 4 2016)

metoffice. (2016) what-katie-did-a-review-of-easter-mondays-storm-katie/. [Online]

Available at: https://blog.metoffice.gov.uk/2016/03/28/what-katie-did-a-review-of-easter-mondays-storm-katie/

(Accessed 21 4 2016)

Physics. (2016) drag-coefficient. [Online]

Available at: http://physics.stackexchange.com/questions/201633/what-shape-has-the-highest-drag-

coefficient/201664

(Accessed 21 4 2016)

planningni.gov.uk. (2008) vehicular-access. [Online]

Available at: http://www.planningni.gov.uk/downloads/dcan15-vehicular-access.pdf

(Accessed 21 4 2016)](https://image.slidesharecdn.com/1cac153b-ac42-48a9-9a62-a304a88c070f-160923222548/75/Advanced-Mechanical-Design-and-Material-6ME503-59-2048.jpg)

![Advanced Mechanical Design and Materials

P a g e 59 | 63

steelexpress. (2016) S355-S275-structural-steel. [Online]

Available at: http://www.steelexpress.co.uk/structuralsteel/S355-S275-structural-steel.html

(Accessed 21 4 2016)

metoffice. (2016) windiest-place-in-UK. [Online]

Available at: http://www.metoffice.gov.uk/learning/wind/windiest-place-in-UK

(Accessed 21 04 2016)

Bibliography

Ashby, M. F. (2011) Material Selection in Mechanical Design. 4th ed. Oxford: Elsevier.

Dingle, M. T. a. L. (2008) Higher National Engineering. 2nd ed. Oxford: Elsevier.

javelin-tech. (2016) solidworks-simulation-accuracy. [Online]

Available at: http://www.javelin-tech.com/blog/2015/01/solidworks-simulation-accuracy/

(Accessed 21 4 2016)

Michael Ashby, H. S. a. D. C. (2014) Engineering, science, Processing, and design. Third ed. Oxford: Elsevier.

Physics. (2016) drag-coefficient. [Online]

Available at: http://physics.stackexchange.com/questions/201633/what-shape-has-the-highest-drag-

coefficient/201664

(Accessed 21 4 2016)

planningni.gov.uk. (2008) vehicular-access. [Online]

Available at: http://www.planningni.gov.uk/downloads/dcan15-vehicular-access.pdf

(Accessed 21 4 2016)

Additionally (Specific CES Request. All images must have the below acknowledgement attached and in

bibliography-Appendix 2)

Charts/data/etc. from “CES EduPack 2015, Granta Design Limited, UK (www.grantadesign.com)”.](https://image.slidesharecdn.com/1cac153b-ac42-48a9-9a62-a304a88c070f-160923222548/75/Advanced-Mechanical-Design-and-Material-6ME503-60-2048.jpg)