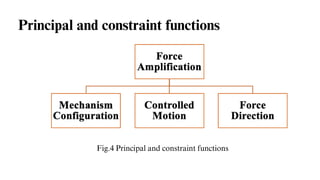

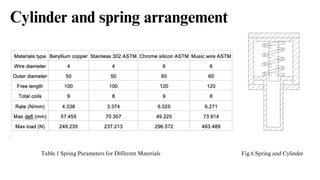

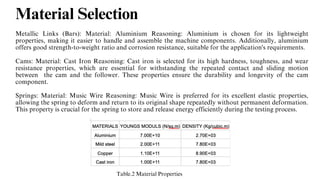

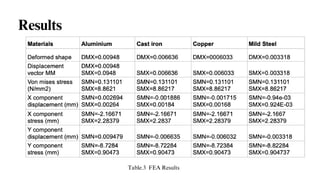

The project focuses on developing a toggle mechanism for a side impact testing machine aimed at improving vehicle safety during side impacts, which are major causes of injuries in accidents. The design incorporates materials like aluminum, cast iron, and music wire to ensure strength, durability, and efficient energy release. Future work includes fabricating a prototype and conducting trials to validate the design and its performance.