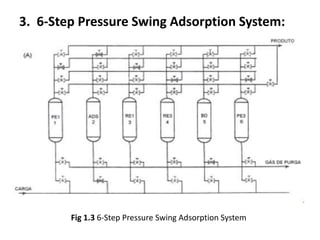

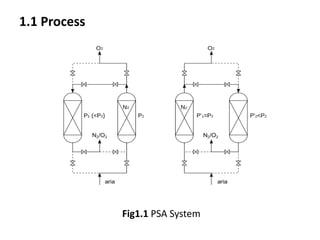

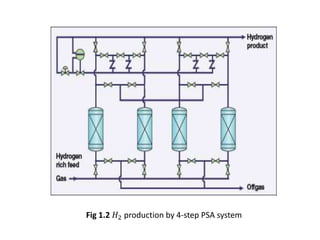

This document summarizes pressure swing adsorption (PSA) systems used for gas separation. It describes the 4-step and 6-step PSA processes. The 4-step process involves pressurization, product removal, depressurization, and purging steps. The 6-step process uses 6 adsorbers that undergo simultaneous pressurization, adsorption, countercurrent purging and depressurization steps. Common adsorbents like zeolites and activated carbon are used based on their selectivity. PSA has applications in oxygen production, hydrogen purification, and biogas upgrading.

![• Step (1): [Pressurization]

In the pressure swing adsorption system, when the adsorption column

which is filled with feed is pressurized at that time product line valve is

kept closed.

• Step (2): [Product removal]

Adsorption at high pressure with the withdrawal of the product at the

constant rate. Doing the stage, Feed is continuously fed to the to the

adsorption column and the product is continuously withdrawal from the

column. In pressure swing adsorption system, some components are

selectively adsorbed via. Vander waal force.](https://image.slidesharecdn.com/astpptchemrolln0353637-171005122455/85/Advance-Seperation-Technique-PSA-System-11-320.jpg)

![• Step (3): [Depressurization]

In depressurization step, the column is depressurized and the product line

valve is kept close. During depressurization, gases compounds which are

attached via low Vander waal forces are removed. But components which

are attached via strong Vander waal binding force are not removed in this

stage.

• Step (4): [Purging]

The purging occur at low pressure or under vacuumed. Purging is done in

counter current direction or in reverse direction of feed. As a purg gas in

most of the small fraction of product gas is use in the step components

which are attached via strong binding force are also remove and

adsorption bed is regenerated. Partial pressure of the impurities in purg

gas should be less than the same in the feed gas.](https://image.slidesharecdn.com/astpptchemrolln0353637-171005122455/85/Advance-Seperation-Technique-PSA-System-12-320.jpg)