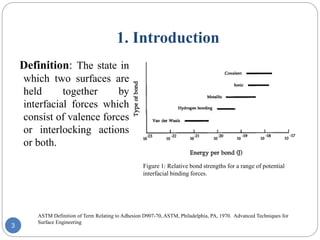

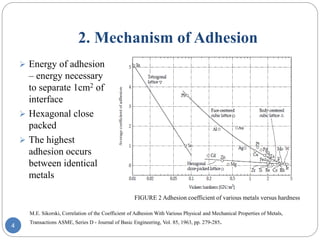

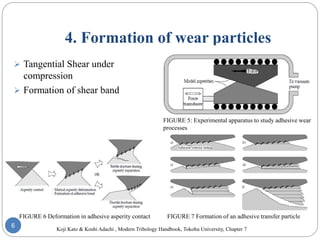

The presentation on adhesion discusses its definition, mechanisms, and the role of friction in adhesion, alongside methods for reducing adhesion such as using harder materials and lubricants. It highlights the formation of wear particles and provides an example of mechanical seals, emphasizing that while contaminants can reduce adhesion, it cannot be completely eliminated. The conclusion states that adhesion is a primary cause of failure in metal interactions.

![5. Reducing adhesion

Increasing Hardness[hardness

is most dominant parameter]

Combination of dissimilar

materials

Surface roughness

Use of lubricant

Material with high melting

point

To limit the size of contact

Risk of disappearance of

natural oxide layers

FIGURE 9 Surface roughness comparison

FIGURE 8 Dendrites of zinc electrodeposited onto a zinc surface

David E Pakham,Ch 2, Theories of Fundamental Adhesion, Handbook of Adhesion Technology, Vol 2, Springer

Publication, Pg 22-23

7](https://image.slidesharecdn.com/adhesion-170216203138/85/Adhesion-7-320.jpg)