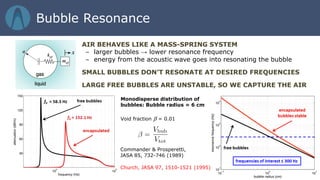

This document discusses an approach to underwater noise abatement using acoustic resonators. It describes how bubble resonance can be used to attenuate noise in the 30-200 Hz range by more than 10 dB. The approach involves using encapsulated bubbles that are tuned to resonate at target frequencies. Recent offshore demonstrations showed the system reduced impact pile driving noise by up to 36.8 dB. New resonator designs improve performance and reduce ballast requirements. The technology has potential applications for treating noise from seismic surveying, shipping, dredging, and explosives.