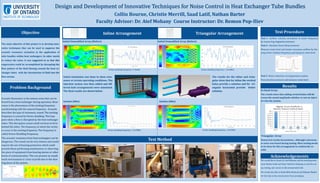

Acoustic resonance occurs when the exciting frequency of vortex shedding from disrupted fluid flow around heat exchanger tubes synchronizes with the natural frequency, producing intense sound. This sound can present safety and economic issues. The objective of this project is to develop techniques to suppress acoustic resonance in heat exchangers by disrupting the flow pattern with fluid injection. Tests were conducted to correlate airflow velocity and noise levels at different motor frequencies and injection pressures. Results showed that adding vertical holes to an inline tube arrangement and horizontal holes to a triangular arrangement helped reduce noise, though more testing is needed for the triangular configuration.