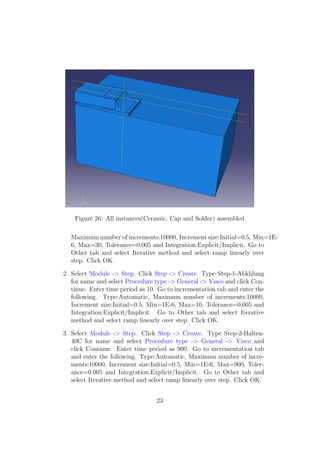

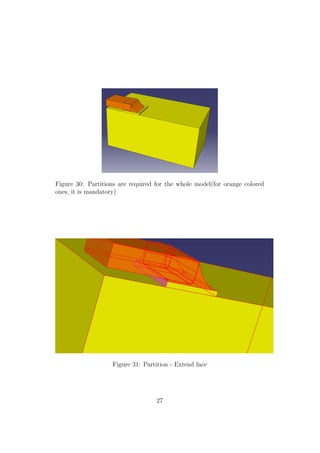

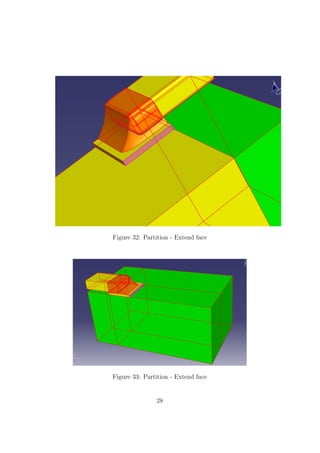

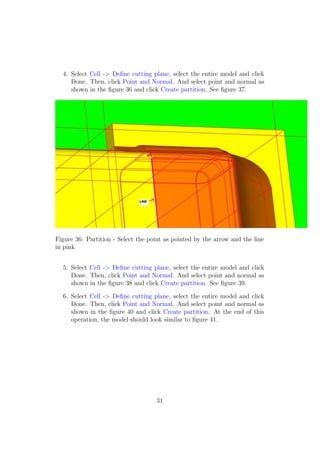

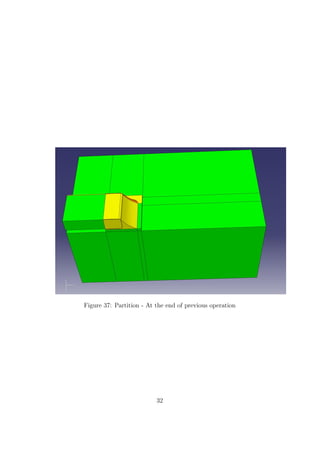

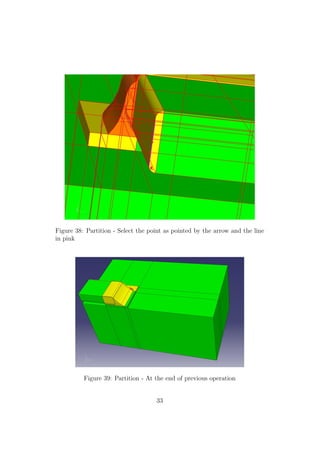

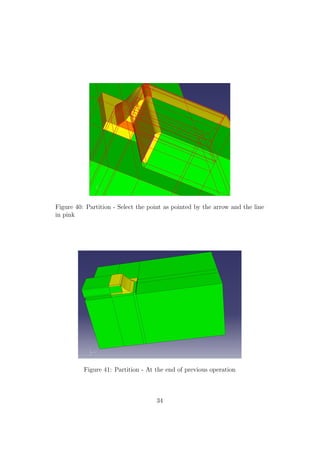

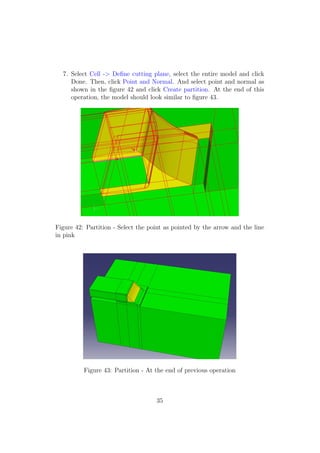

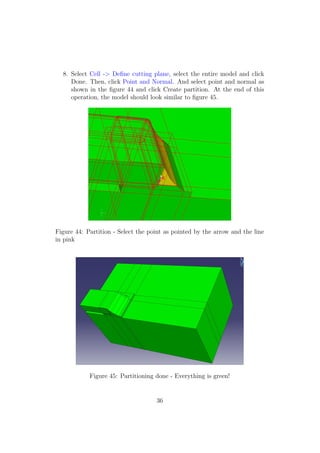

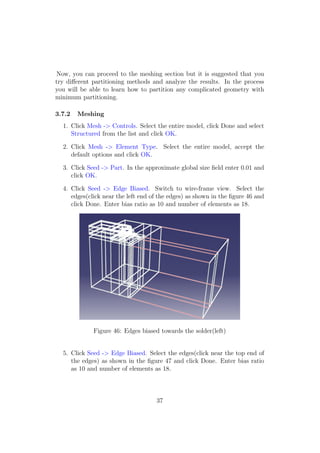

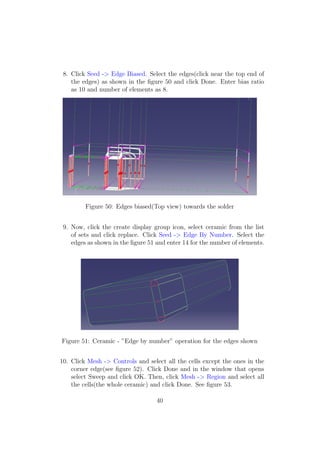

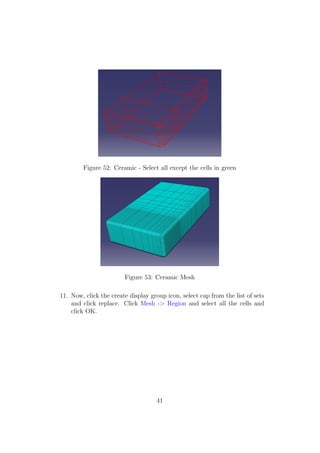

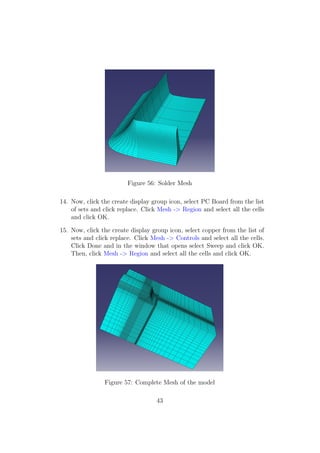

The document describes the steps to create a finite element model in ABAQUS. It involves pre-processing tasks like creating individual parts for the model, assigning material properties, assembling parts, applying loads and boundary conditions, and generating a mesh. Specific steps are provided to create each of the five parts that make up the model - the ceramic, cap, solder, copper, and PC board. Detailed instructions are given on creating the geometry of each part using the part module in ABAQUS. The document also outlines other pre-processing tasks like defining interactions and jobs before solving the model.