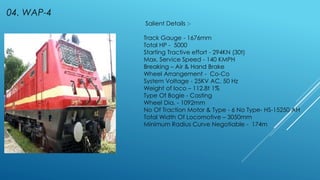

This document provides information about Chittaranjan Locomotive Works (CLW) in India. It discusses the history and establishment of CLW, some key milestones and locomotives produced. It also describes the quality policy, environmental policy and different types of locomotives produced at CLW, including their specifications. Finally, it lists some of the shops visited during a training program at CLW.

![LOCOMOTIVE ENGINE NOMENCLATURE

W - Broad Gauge

(1.676 m)

Y - Meter Gauge

(1m )

Z – Narrow Gauge

(2’6’’)

N – Narrow Gauge

(2’)

1, 2, 3,4…….

Denotes

Model No

M – Mixed Traffic

G – Goods

P – Passenger

S – Shunting

L – Light Duty

R – Rail Car

Alphabets like

E, H etc.

Denotes

rectified locos.

A – AC Power

(25KV)

C – DC Power

(1500V)

D – Diesel Loco

CA – AC/DC

Traction

Locos except older steam ones have classification codes that identified them. The code is as follows : -

[Gauge] [Power] [Load] [Series] [Suffix]](https://image.slidesharecdn.com/6bda346f-abeb-4f49-823a-a3f3971610d9-161229070102/85/CLW-ANKAN-PRESENTATION-Copy-pptx-9-320.jpg)

![EXAMPLE

[W] [A] [P] [4] [E]

WAP 4E

W Means Broad Gauge

i.e. the track width is 1.676m

A Means this is AC powered loco

P Stands for Passenger Train

4 Stands for Model No

E Stands for Rectified loco](https://image.slidesharecdn.com/6bda346f-abeb-4f49-823a-a3f3971610d9-161229070102/85/CLW-ANKAN-PRESENTATION-Copy-pptx-10-320.jpg)