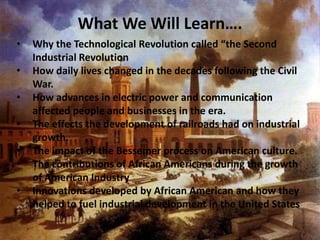

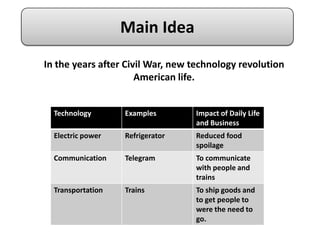

The document summarizes key aspects of the Second Industrial Revolution in the United States following the Civil War, including:

- New technologies like electricity, telegraph communication, and railroads transformed daily life and business by improving transportation of goods and people, enabling longer work hours, and allowing communication over long distances.

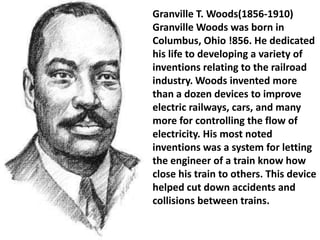

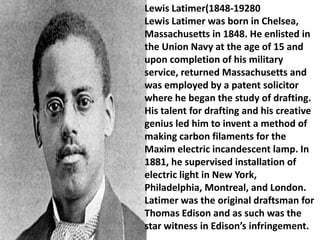

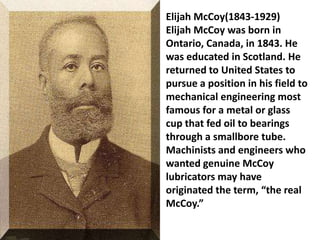

- African American inventors and innovators like Garrett Morgan, Granville Woods, and Lewis Latimer contributed important inventions that advanced industries like rail transport despite facing racial prejudice.

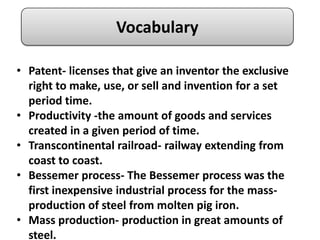

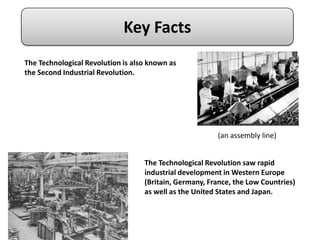

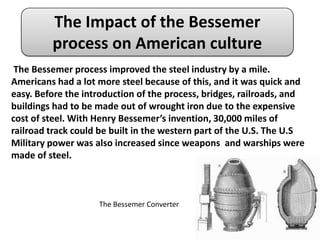

- Major innovations like Henry Bessemer's low-cost process for mass producing steel, Henry Ford's assembly line techniques, and Frederick Taylor's scientific management theories fueled rapid industrial growth.