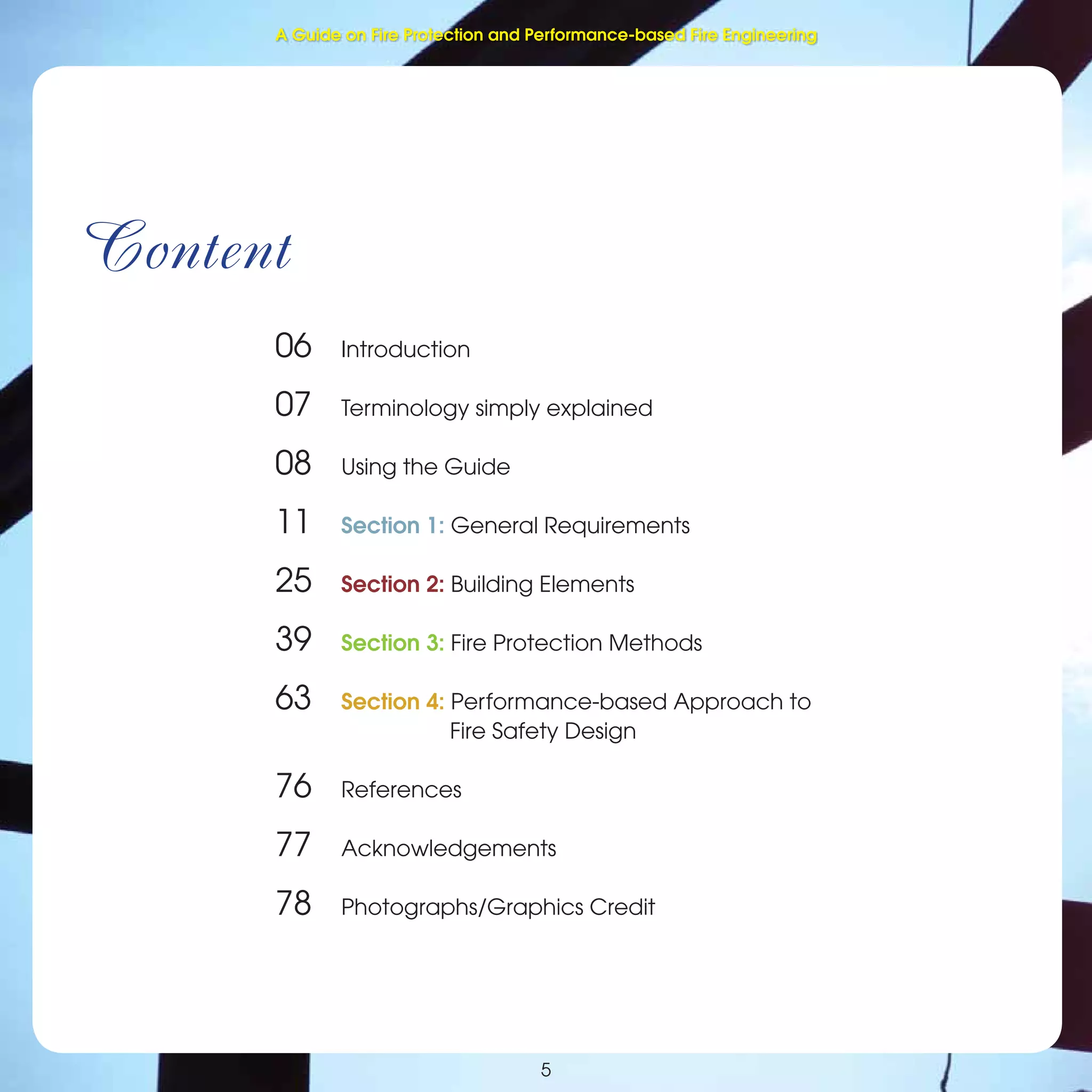

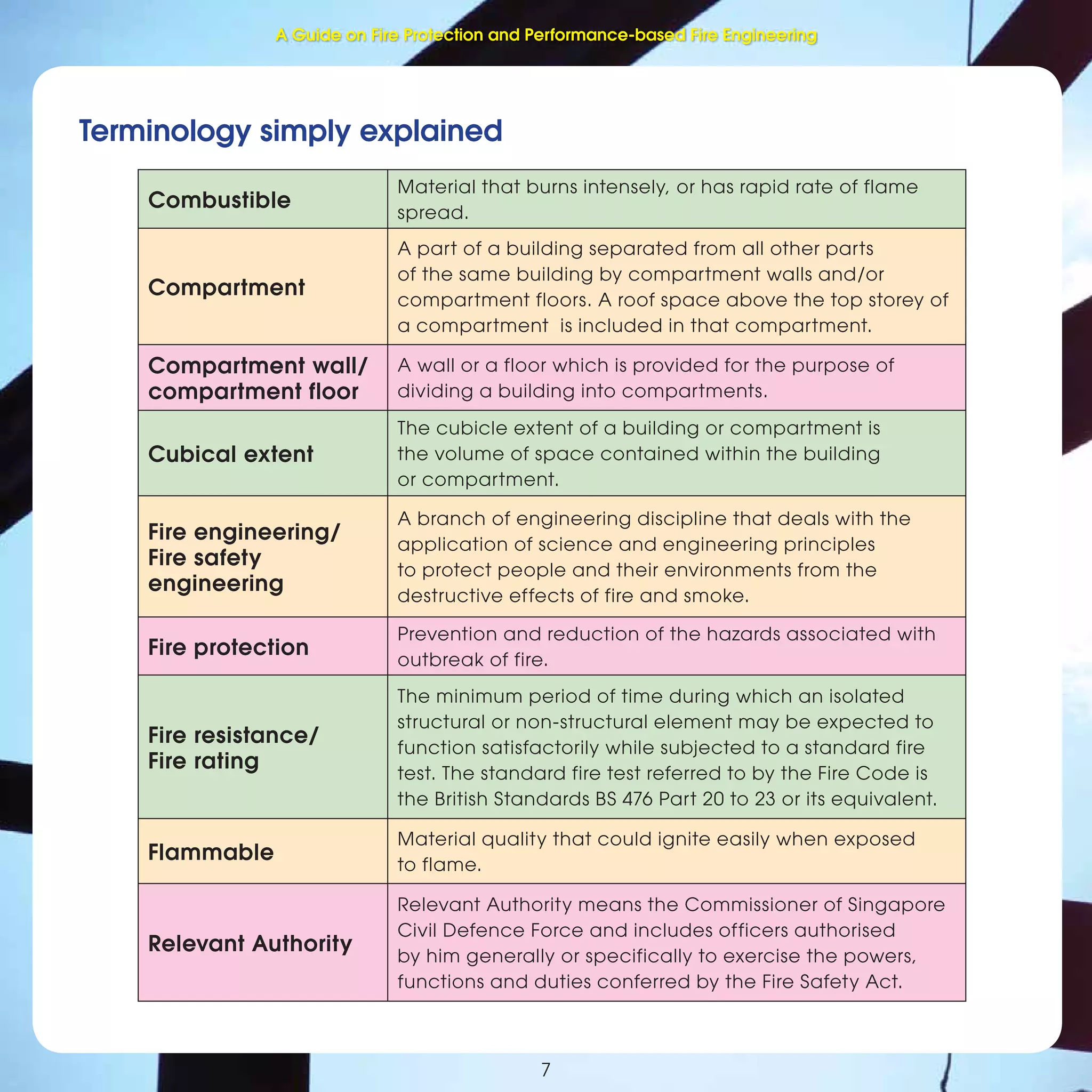

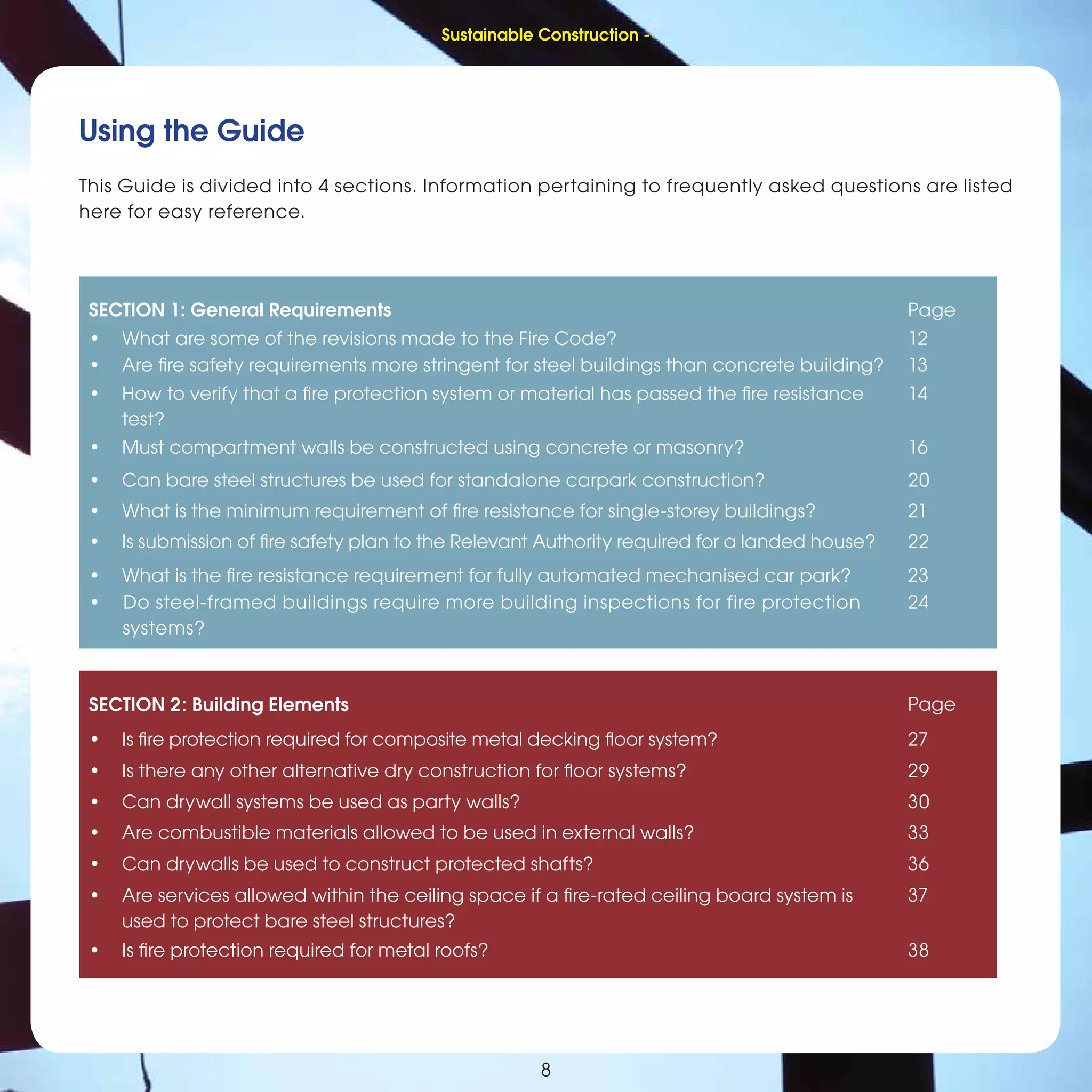

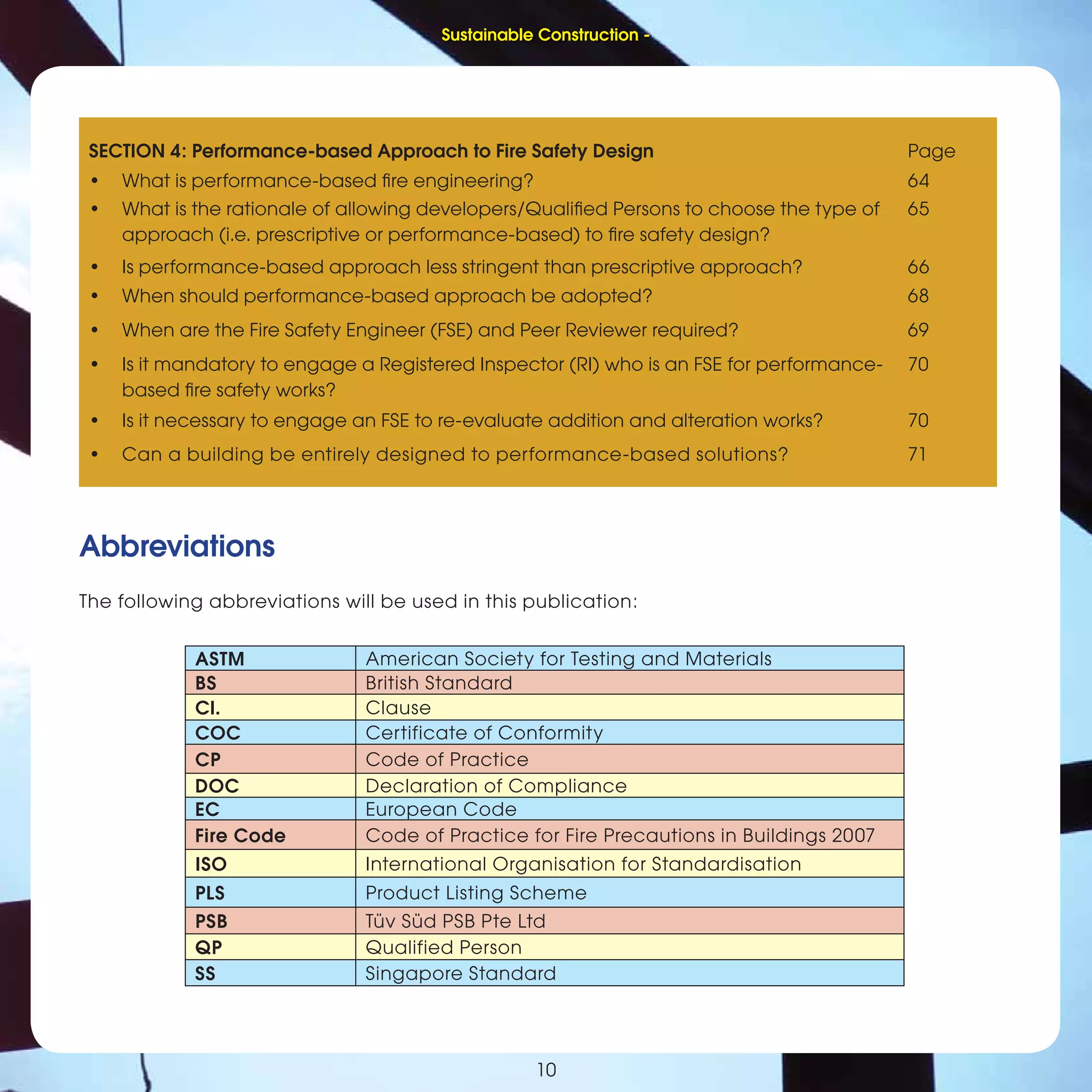

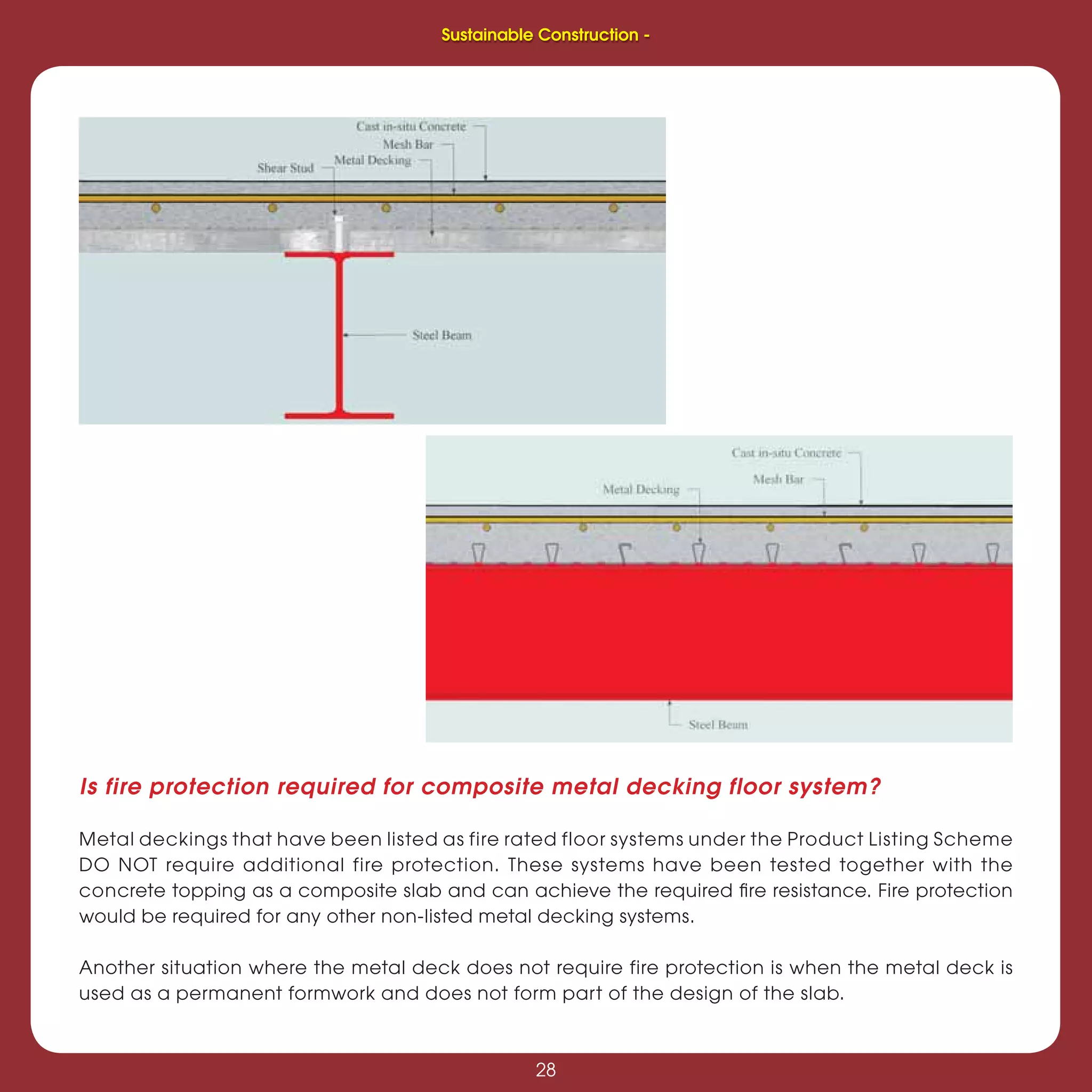

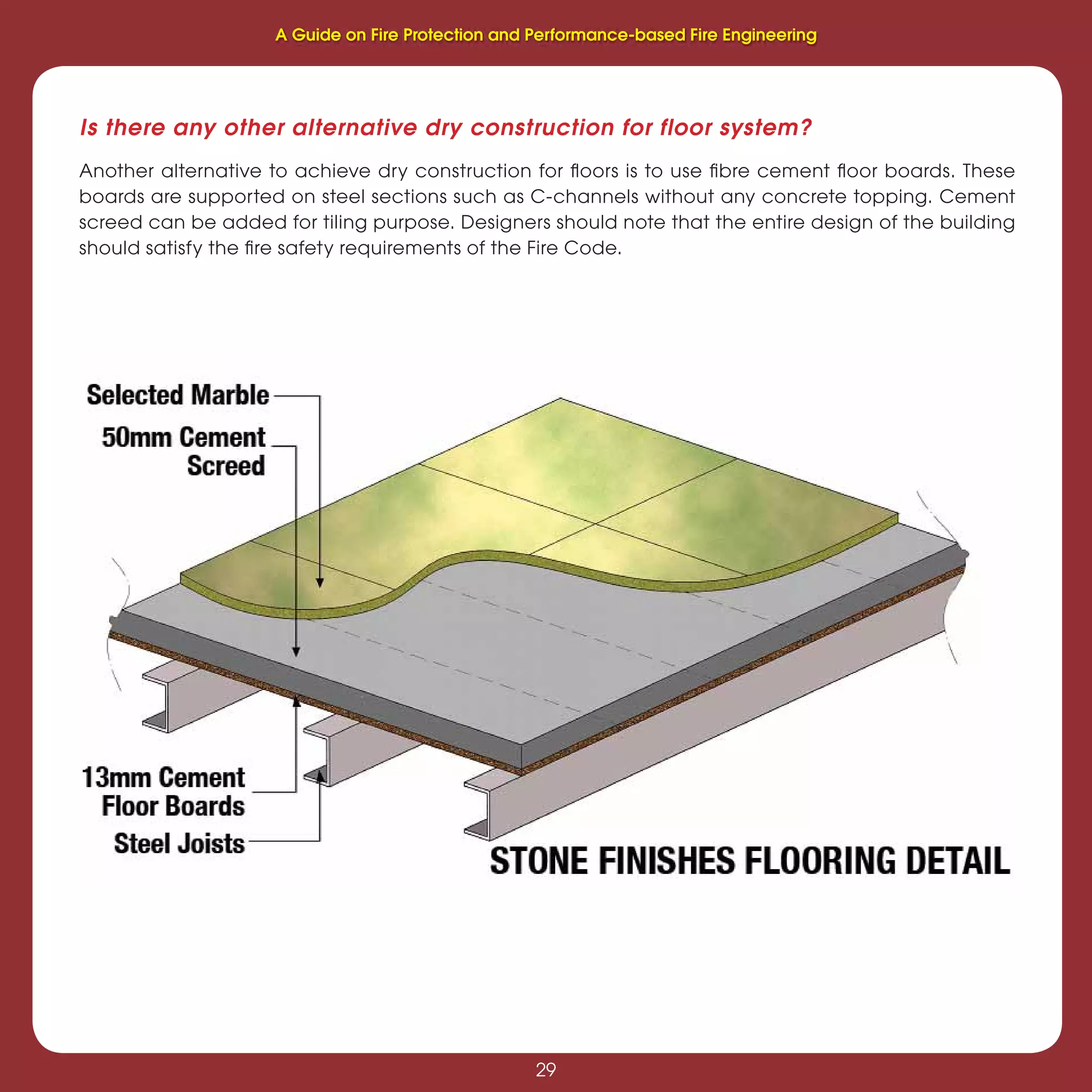

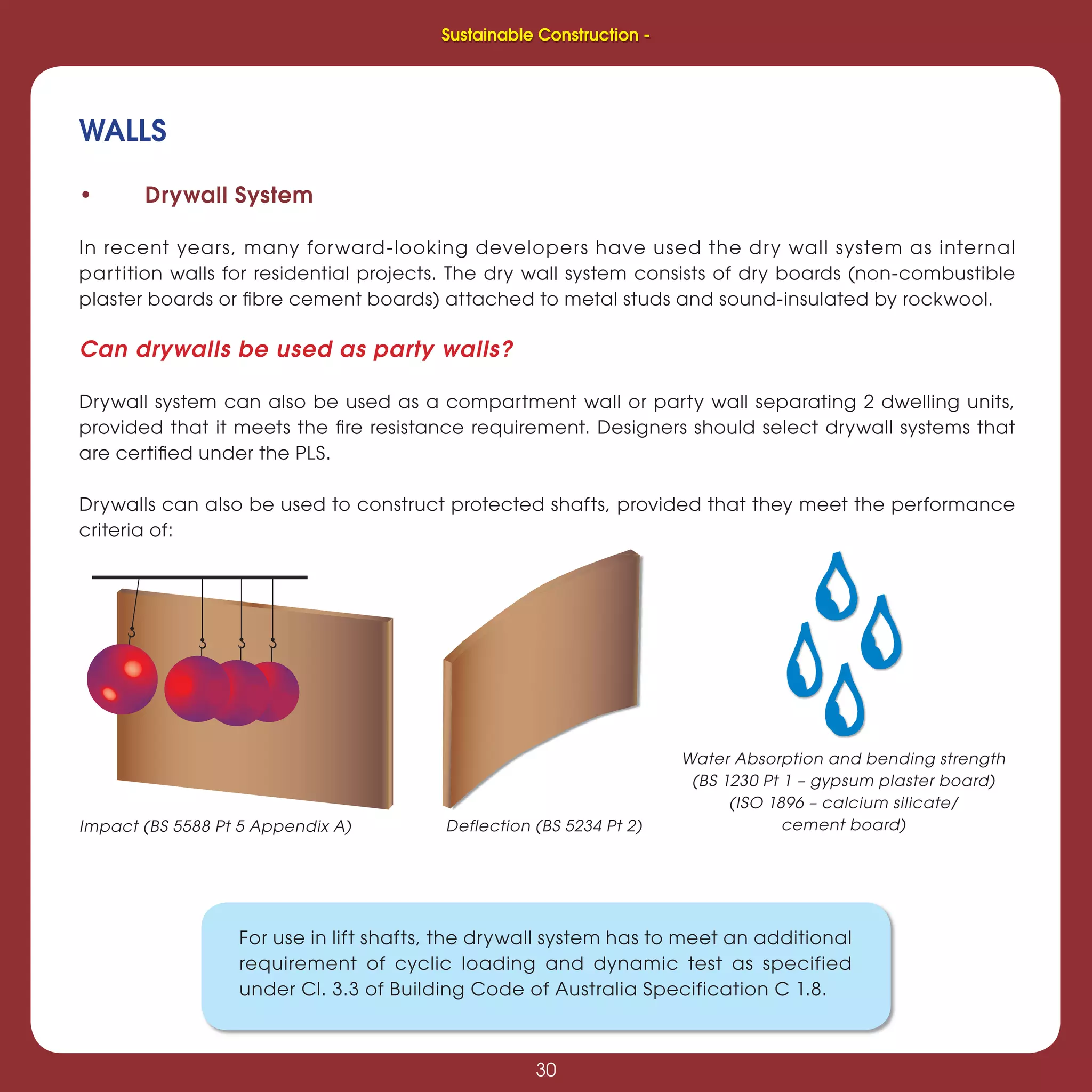

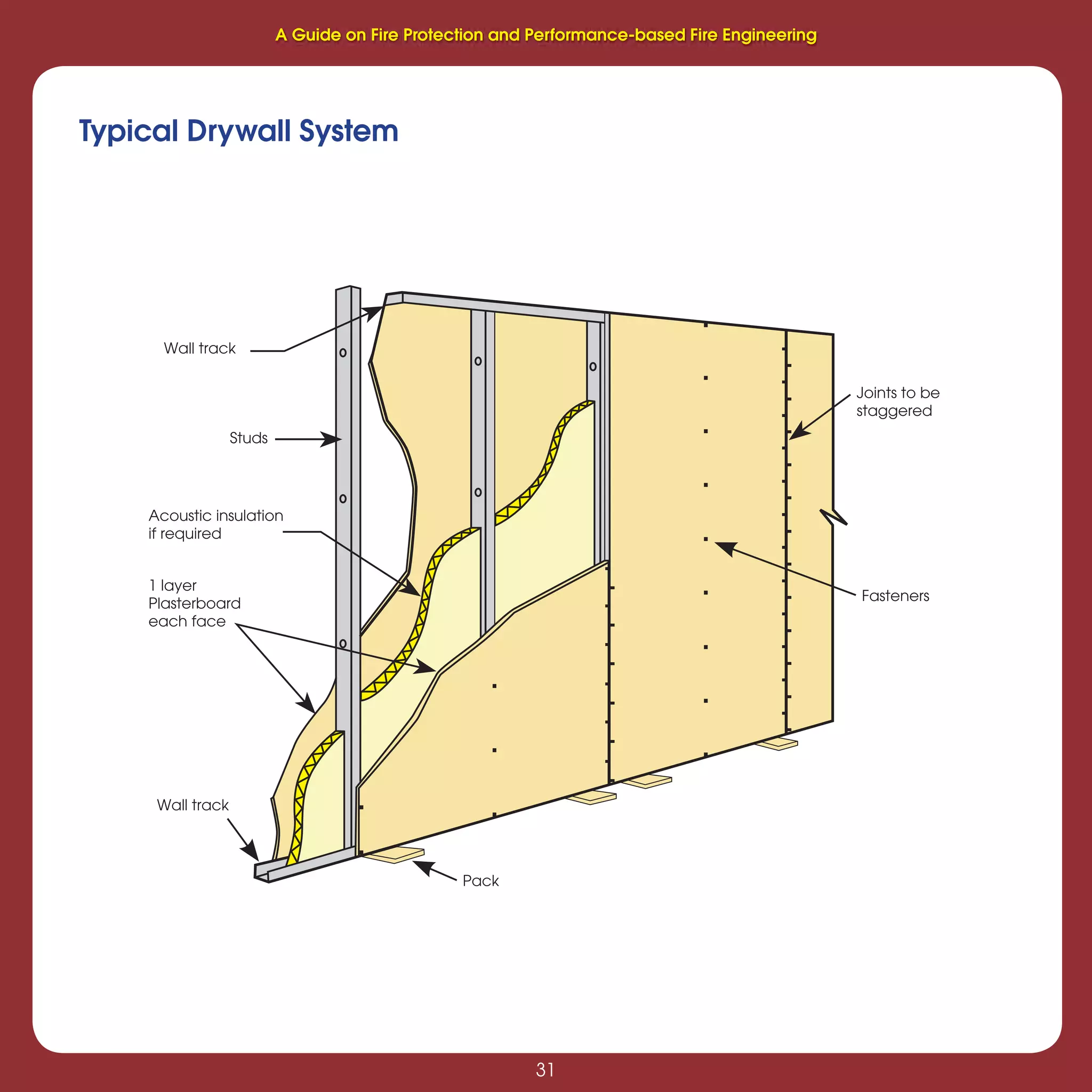

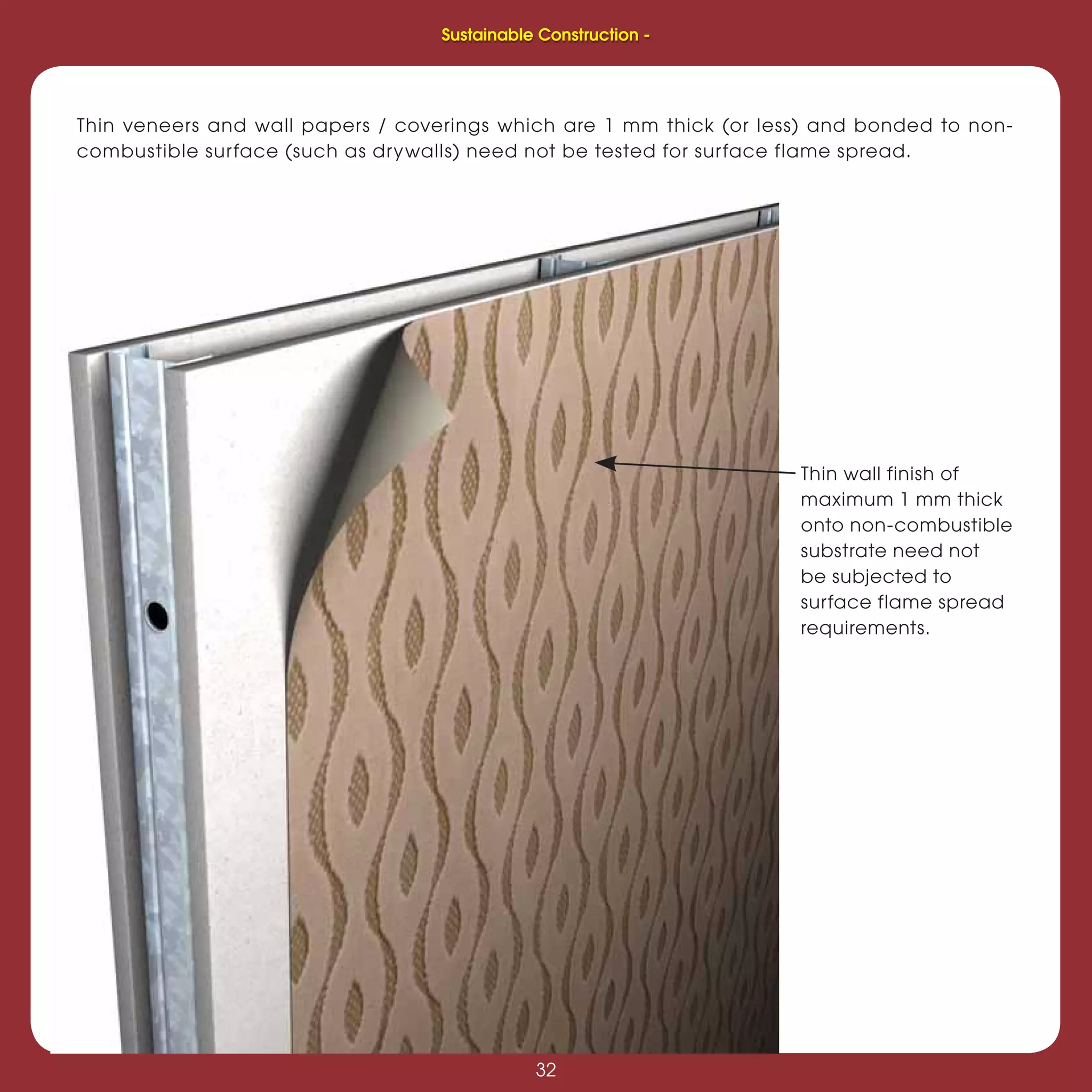

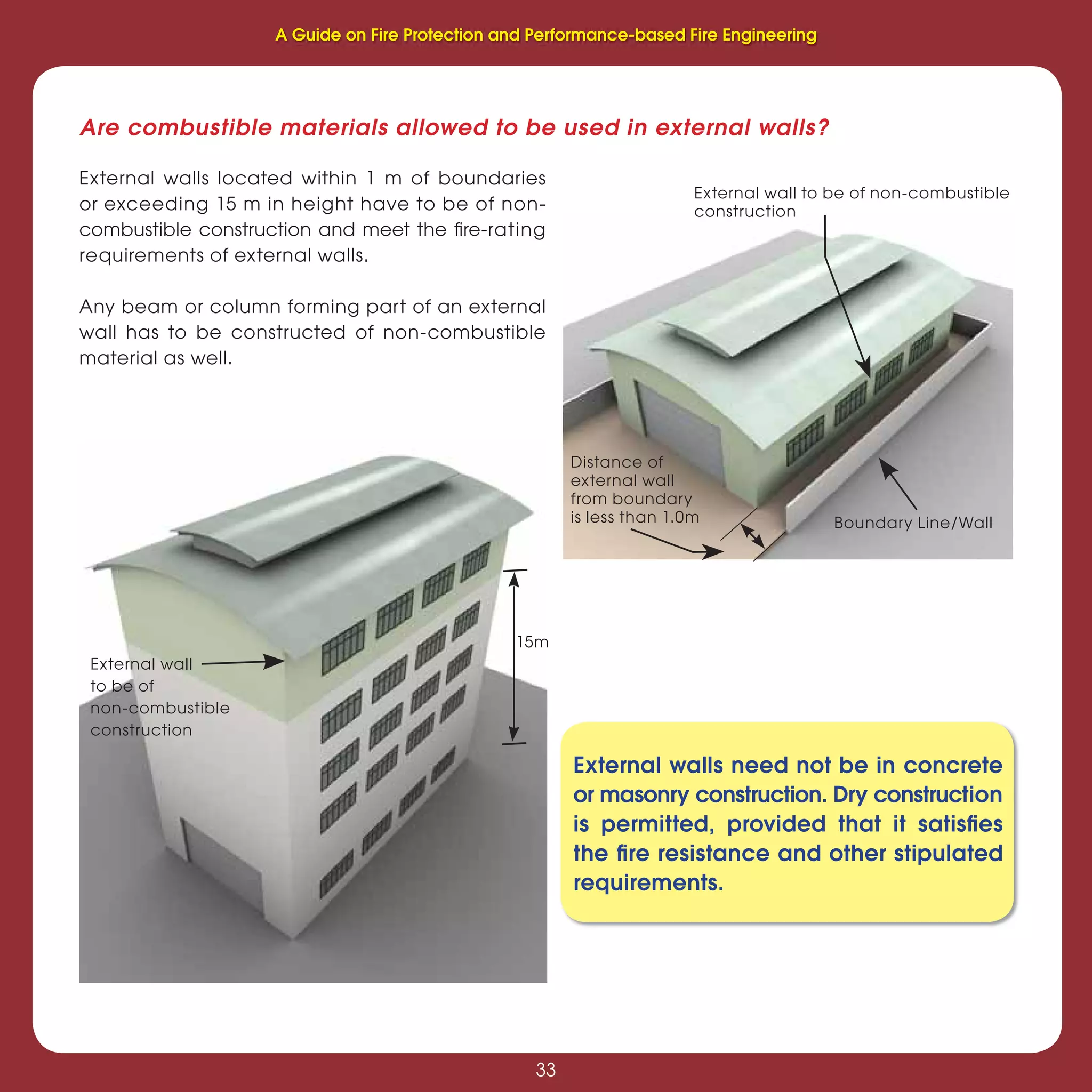

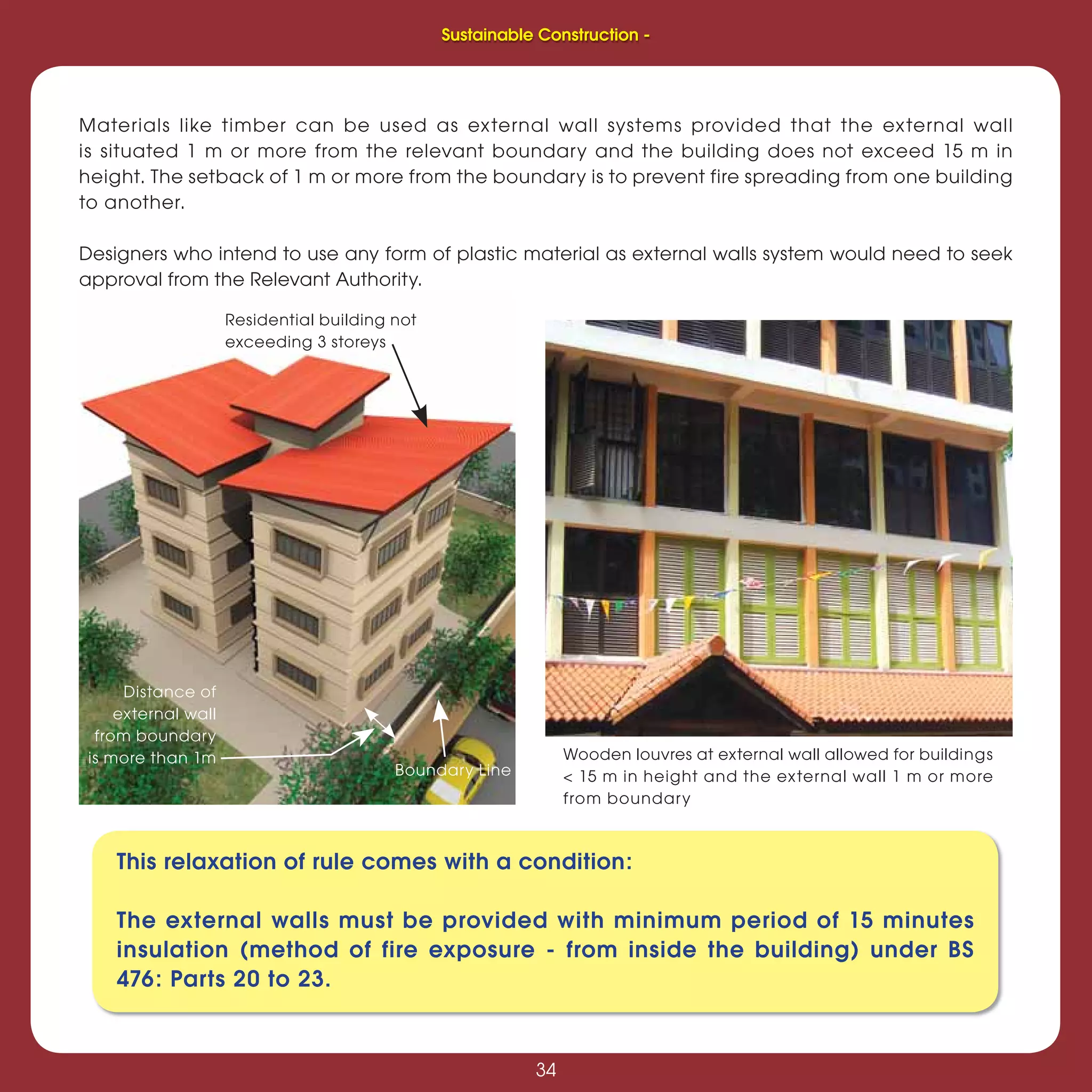

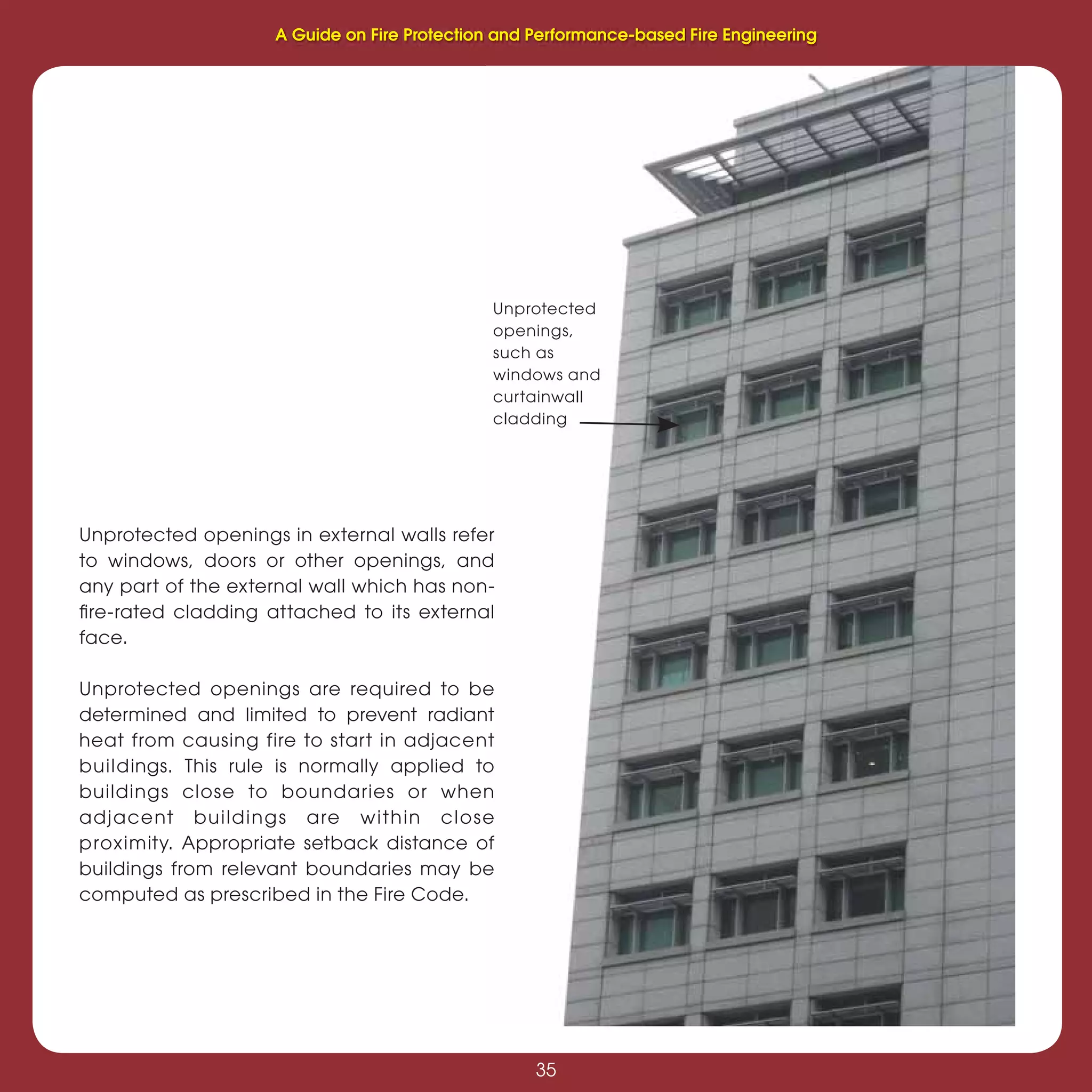

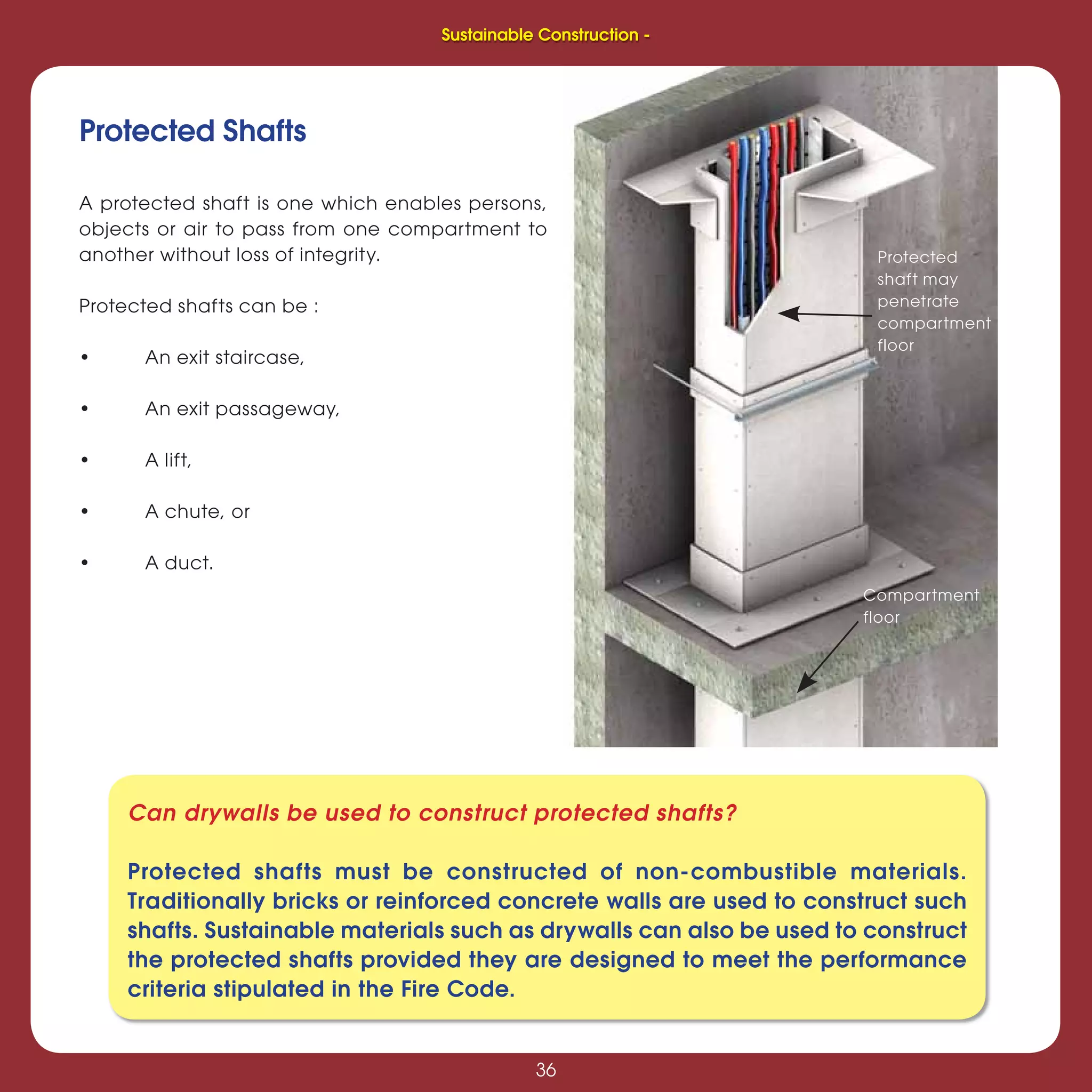

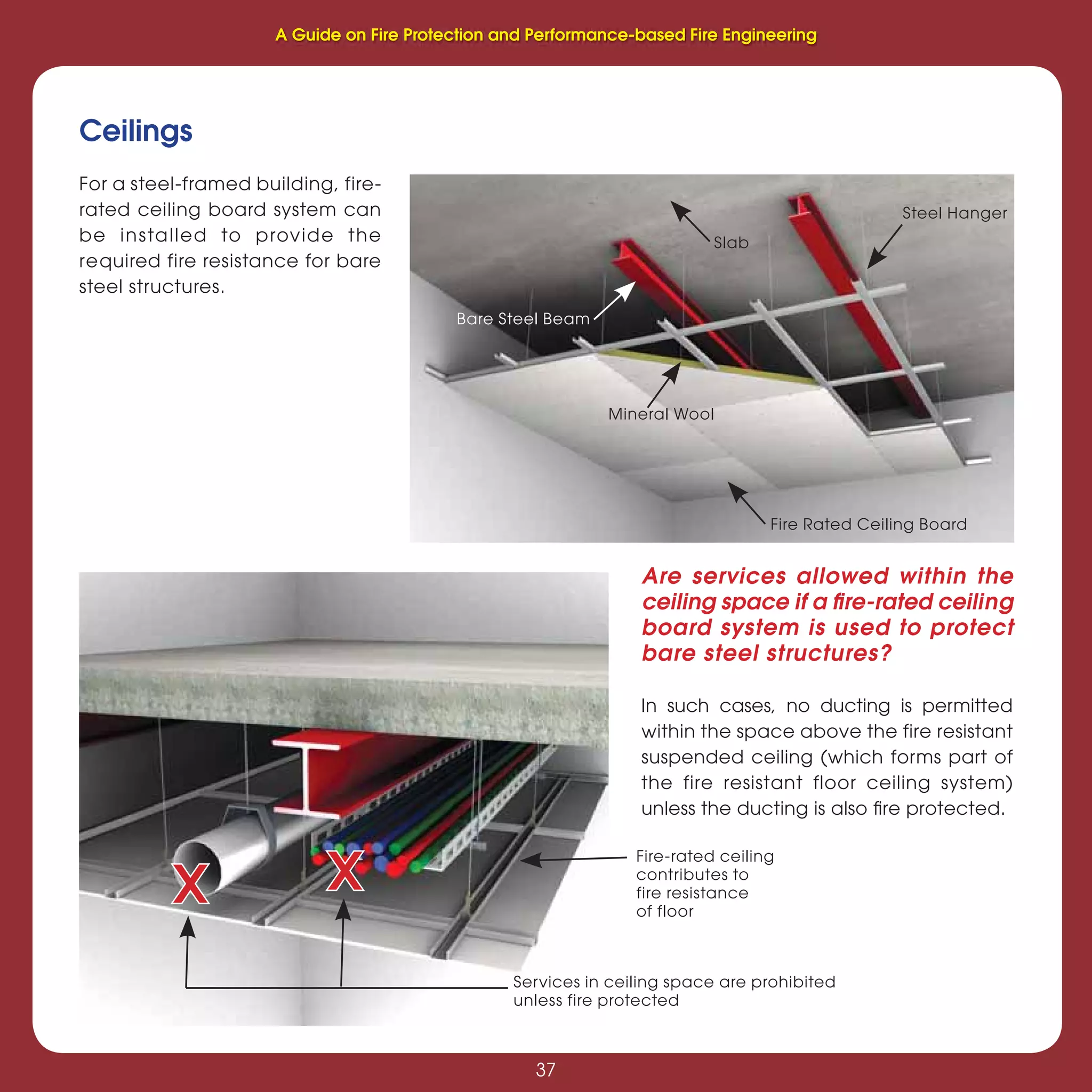

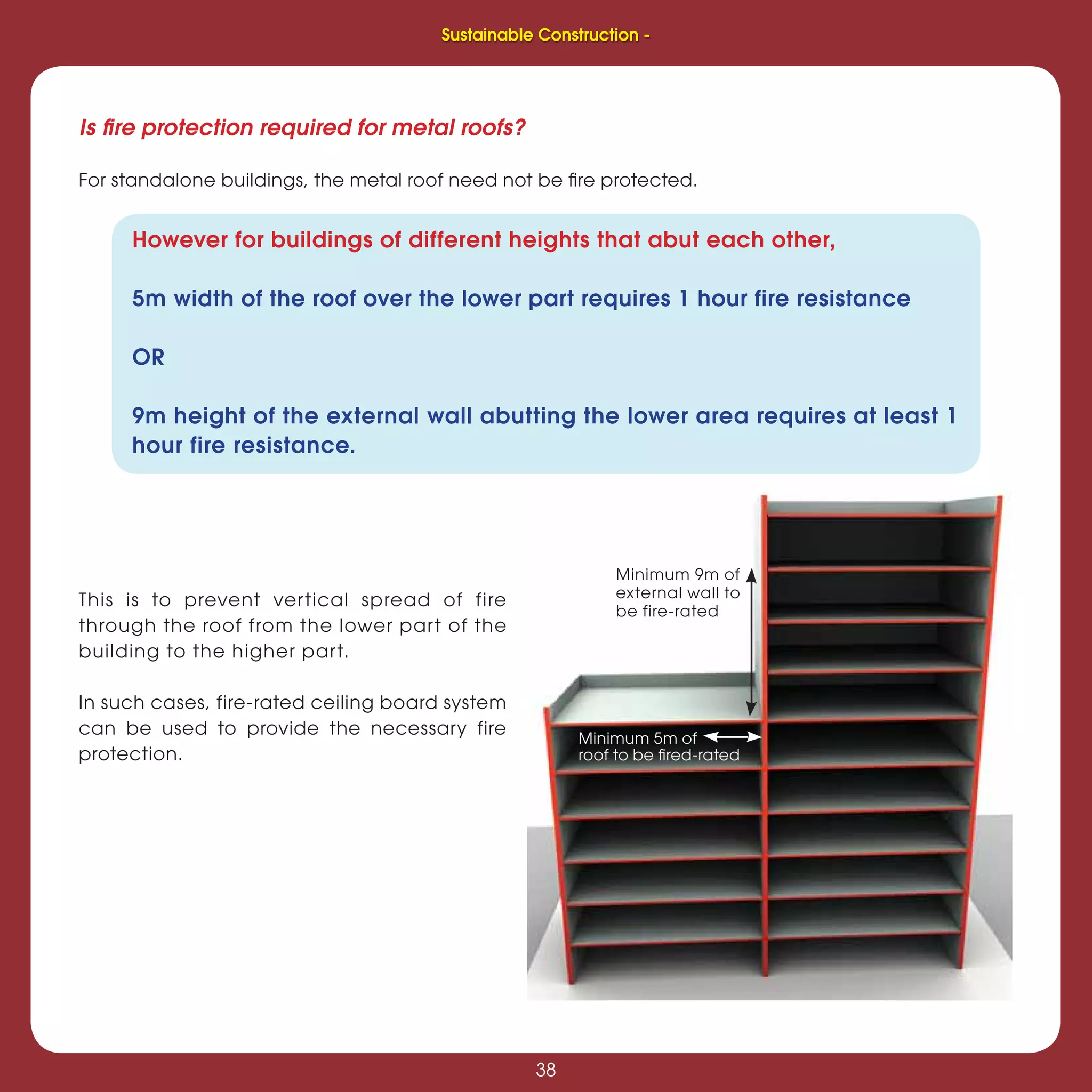

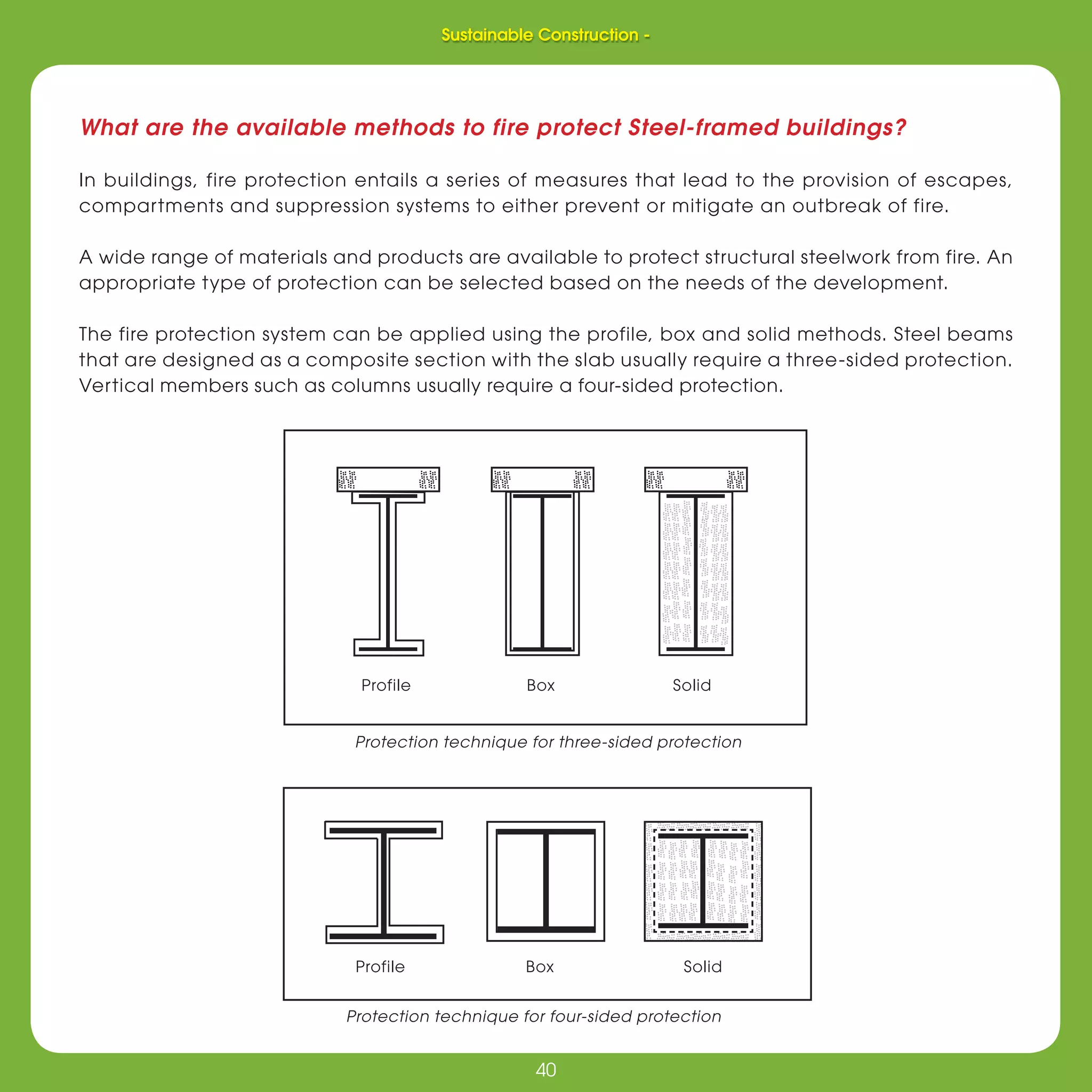

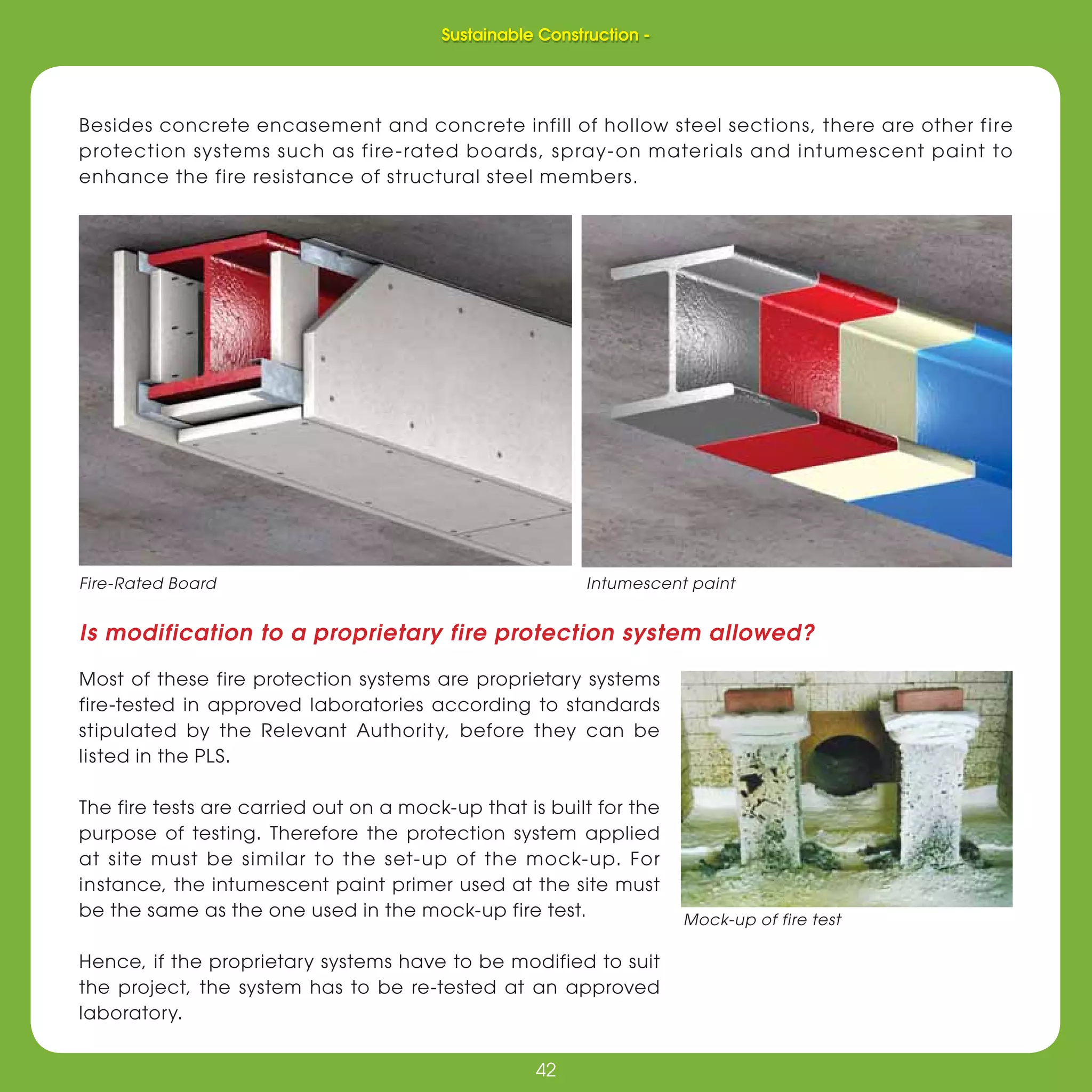

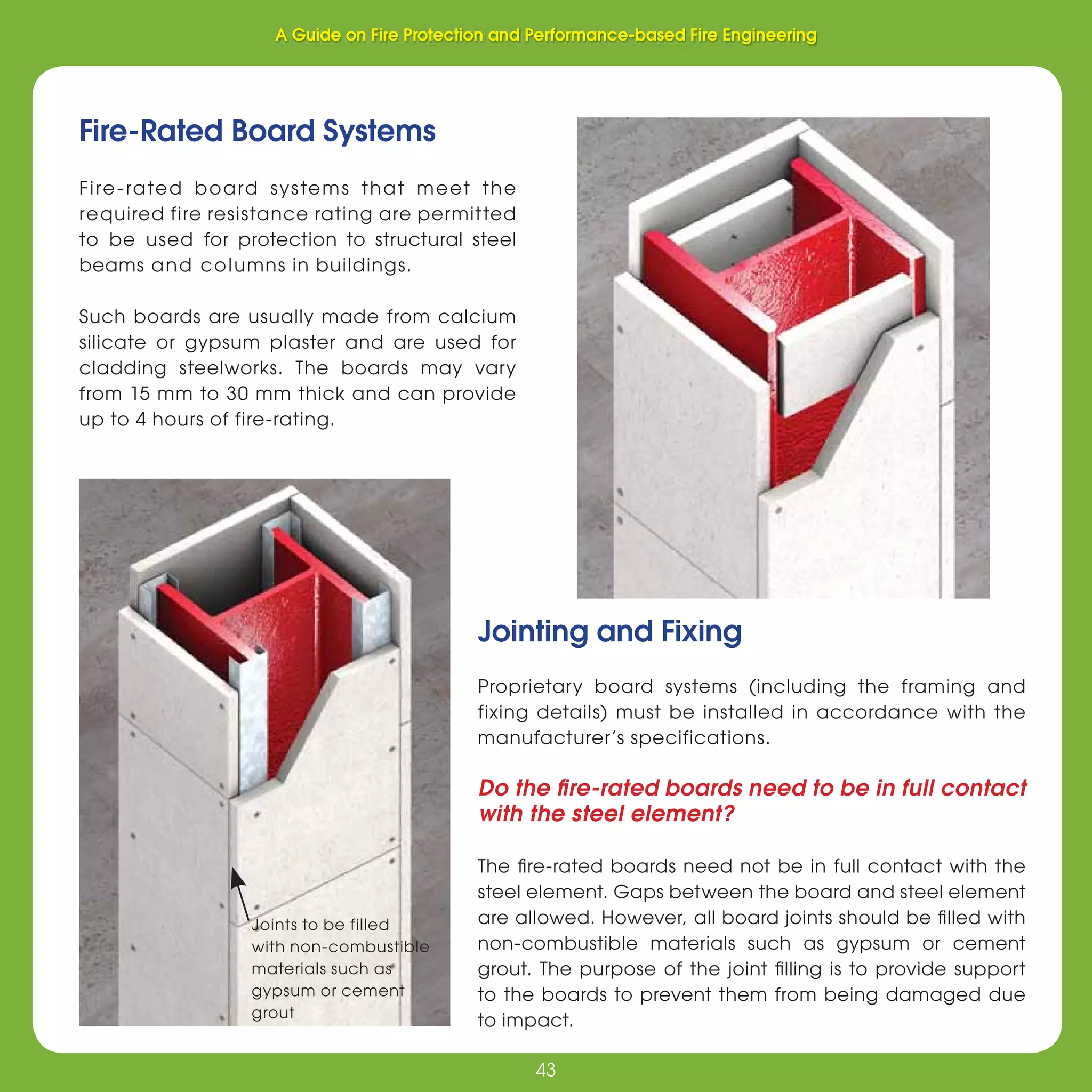

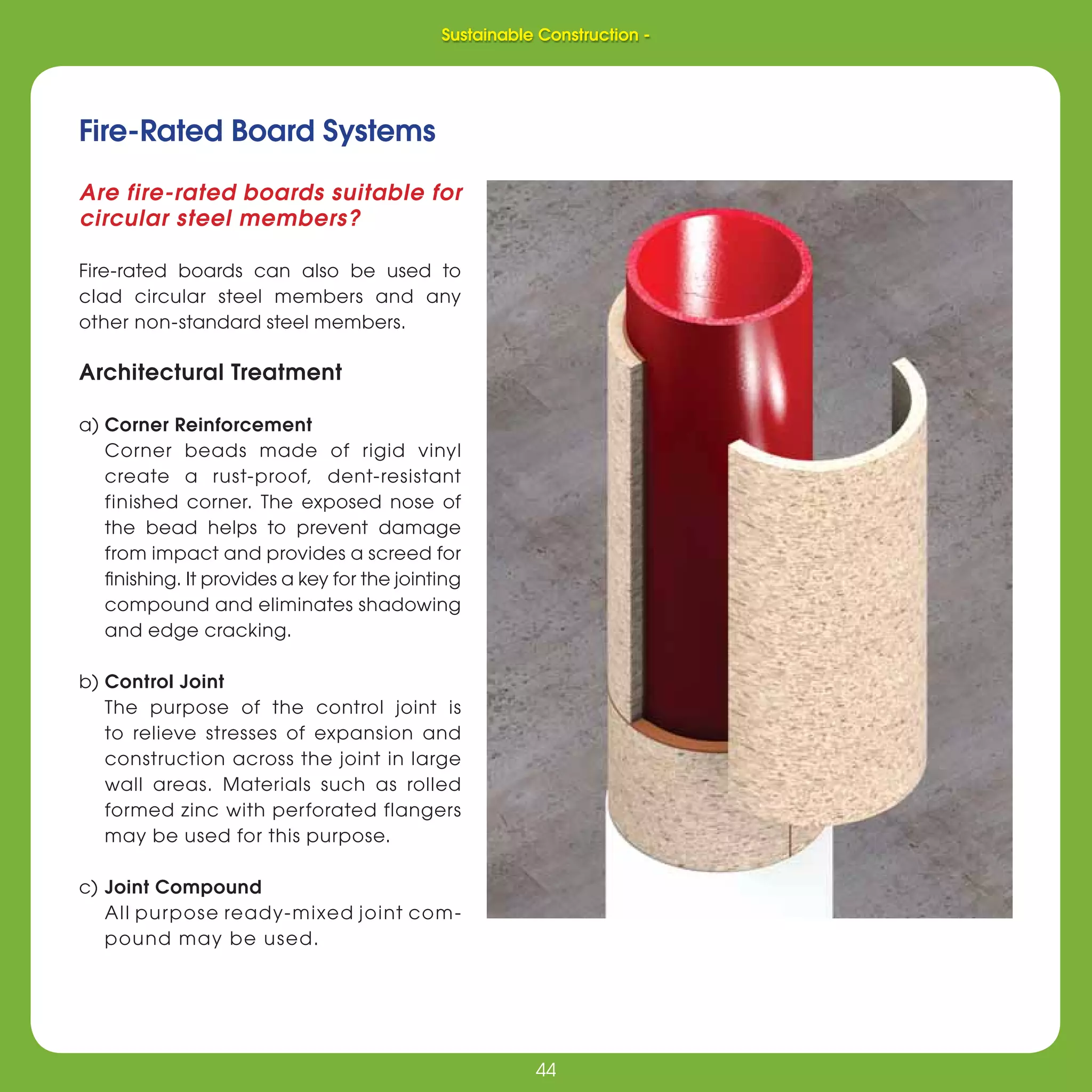

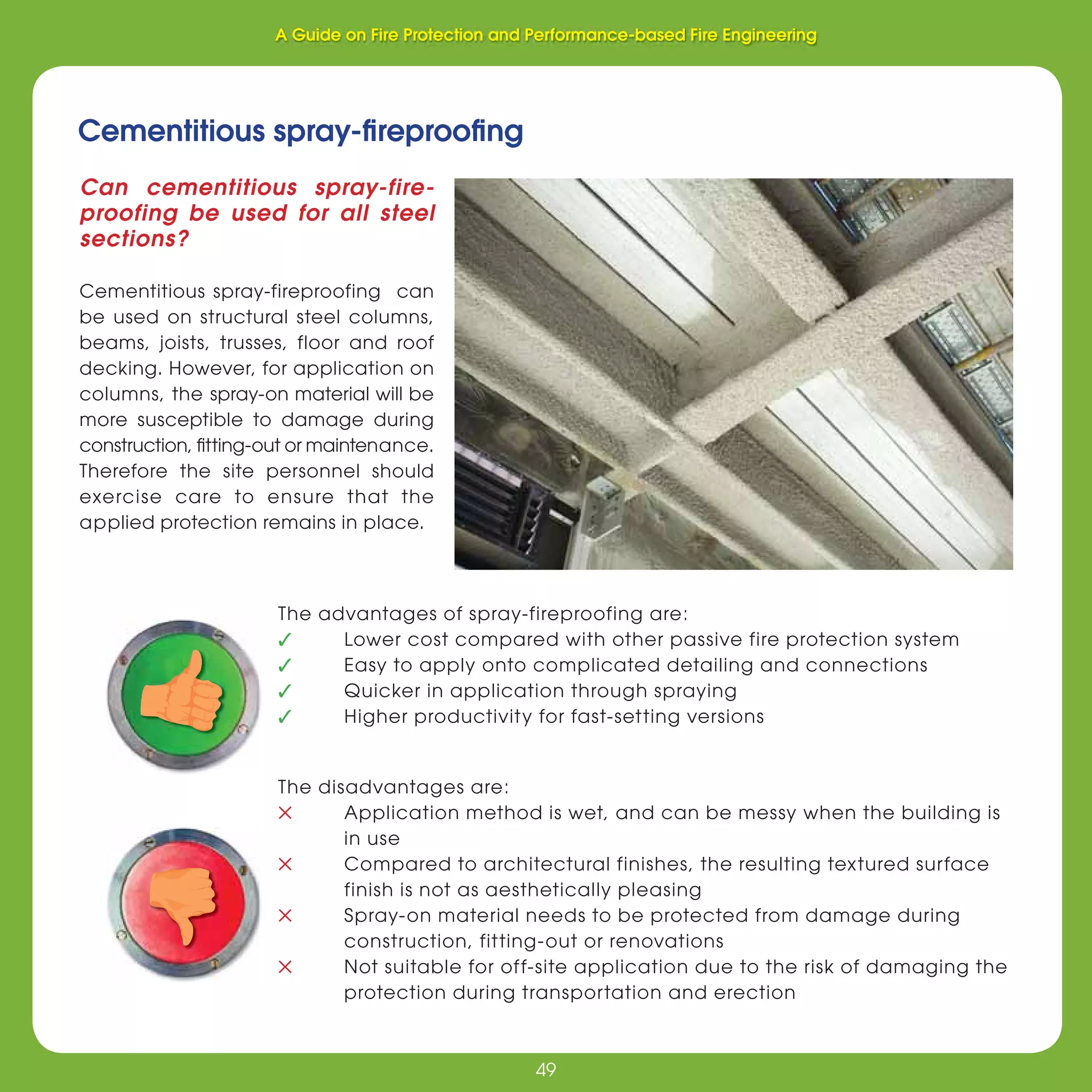

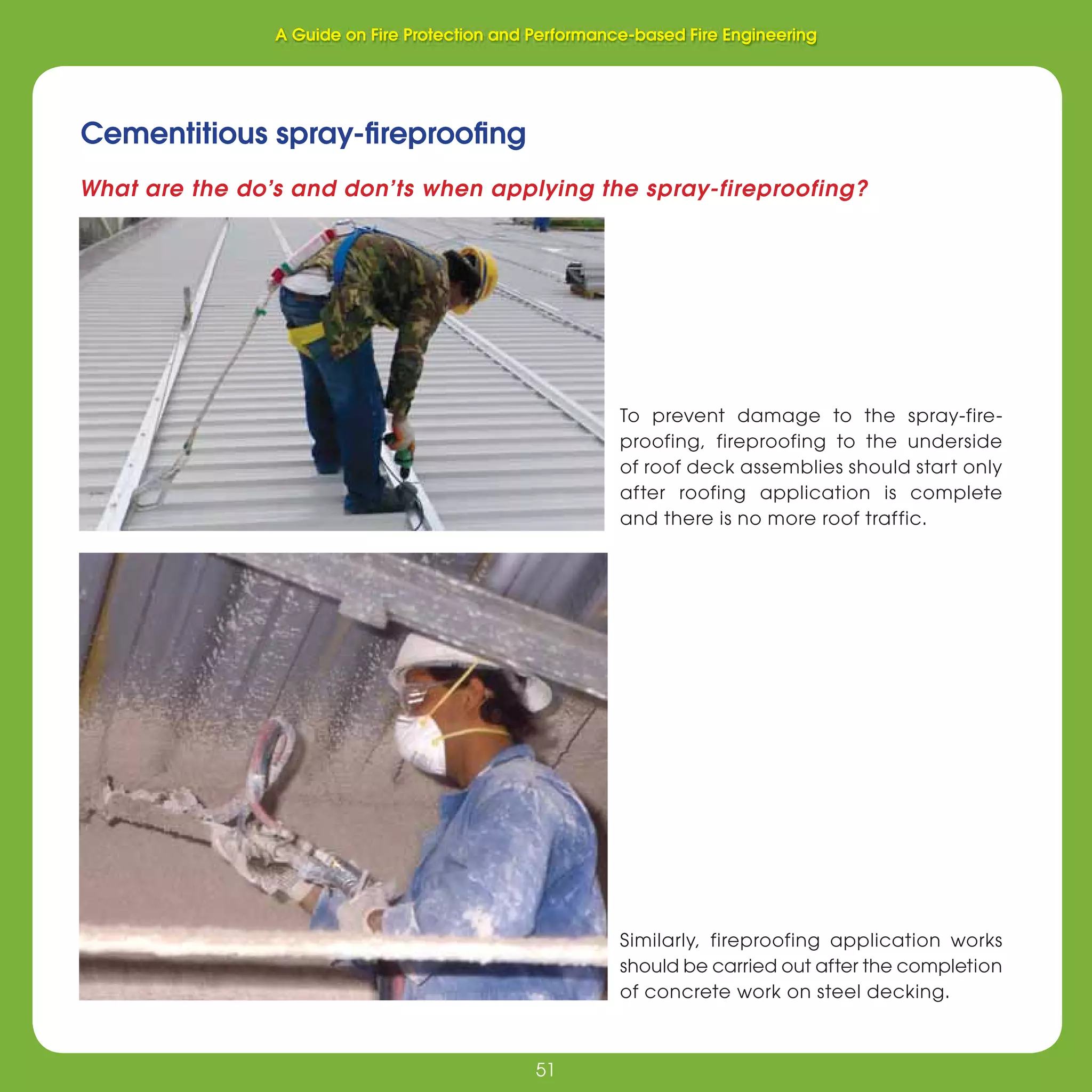

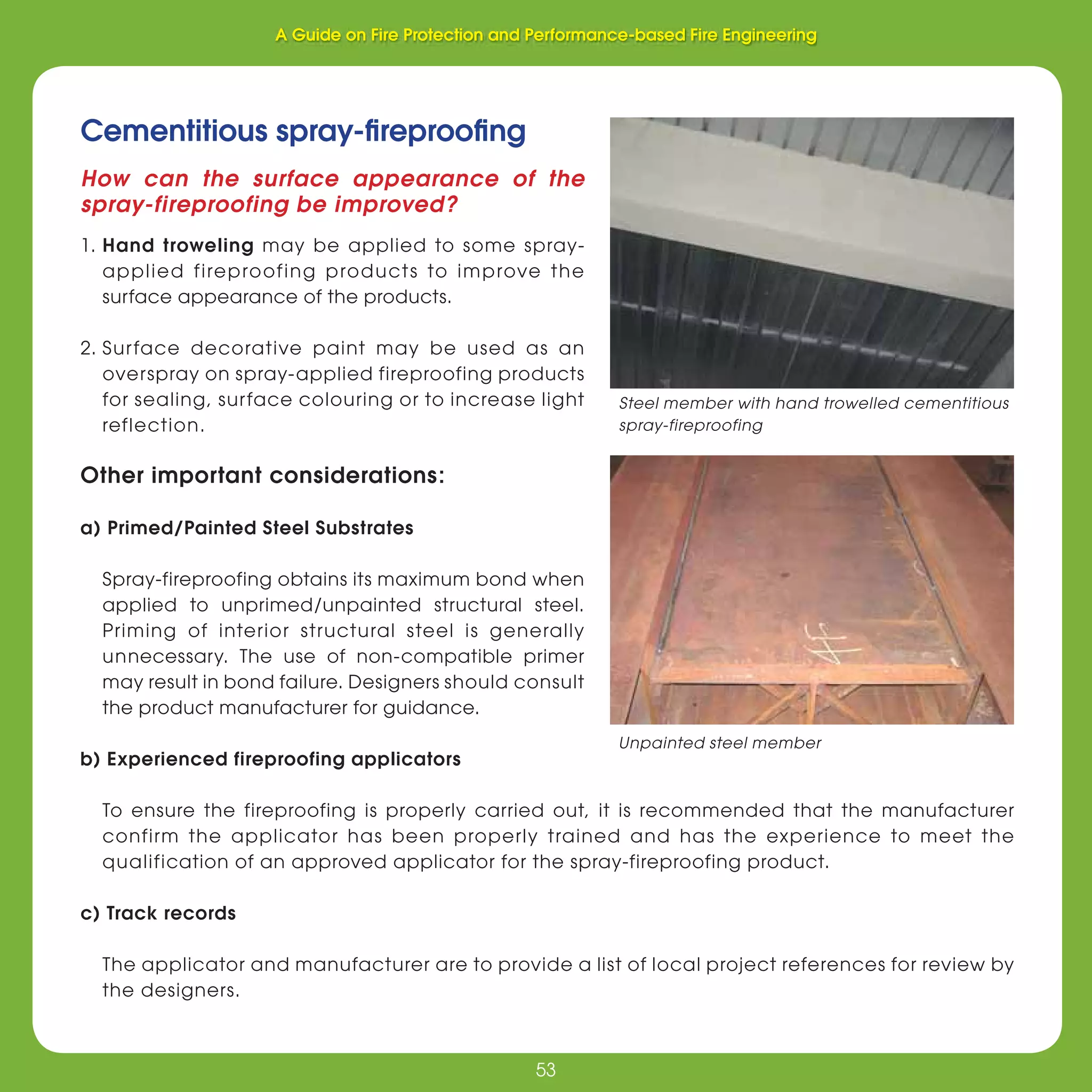

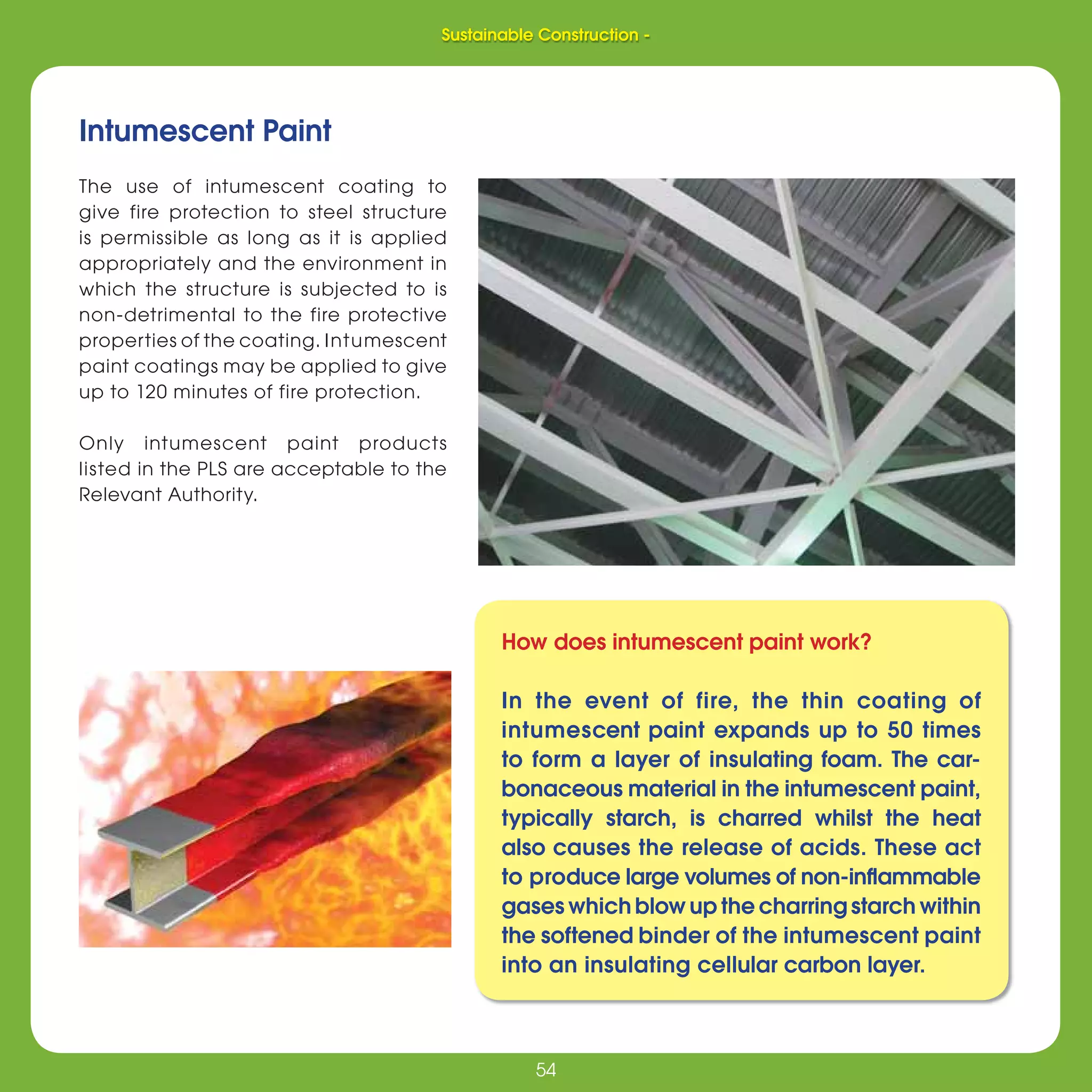

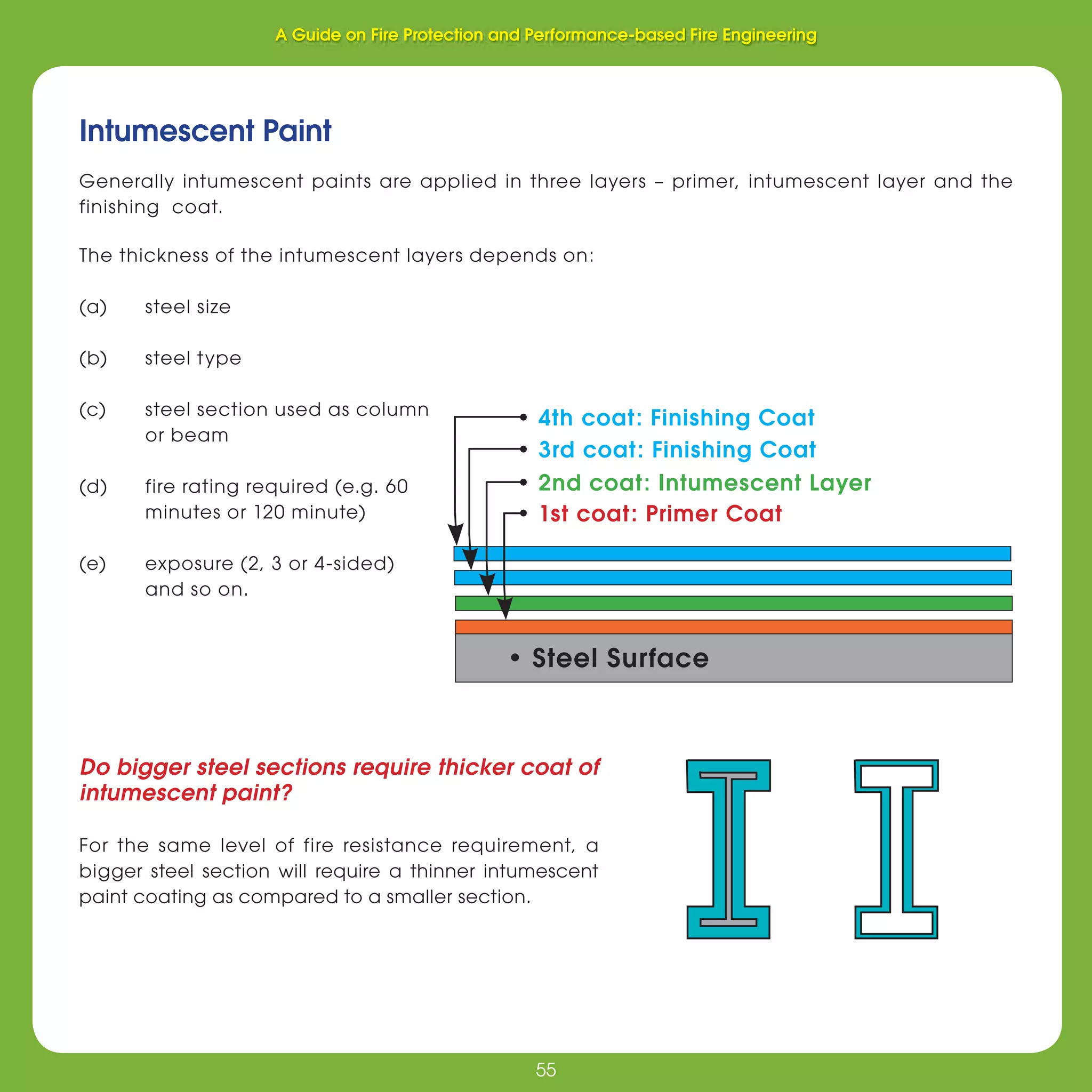

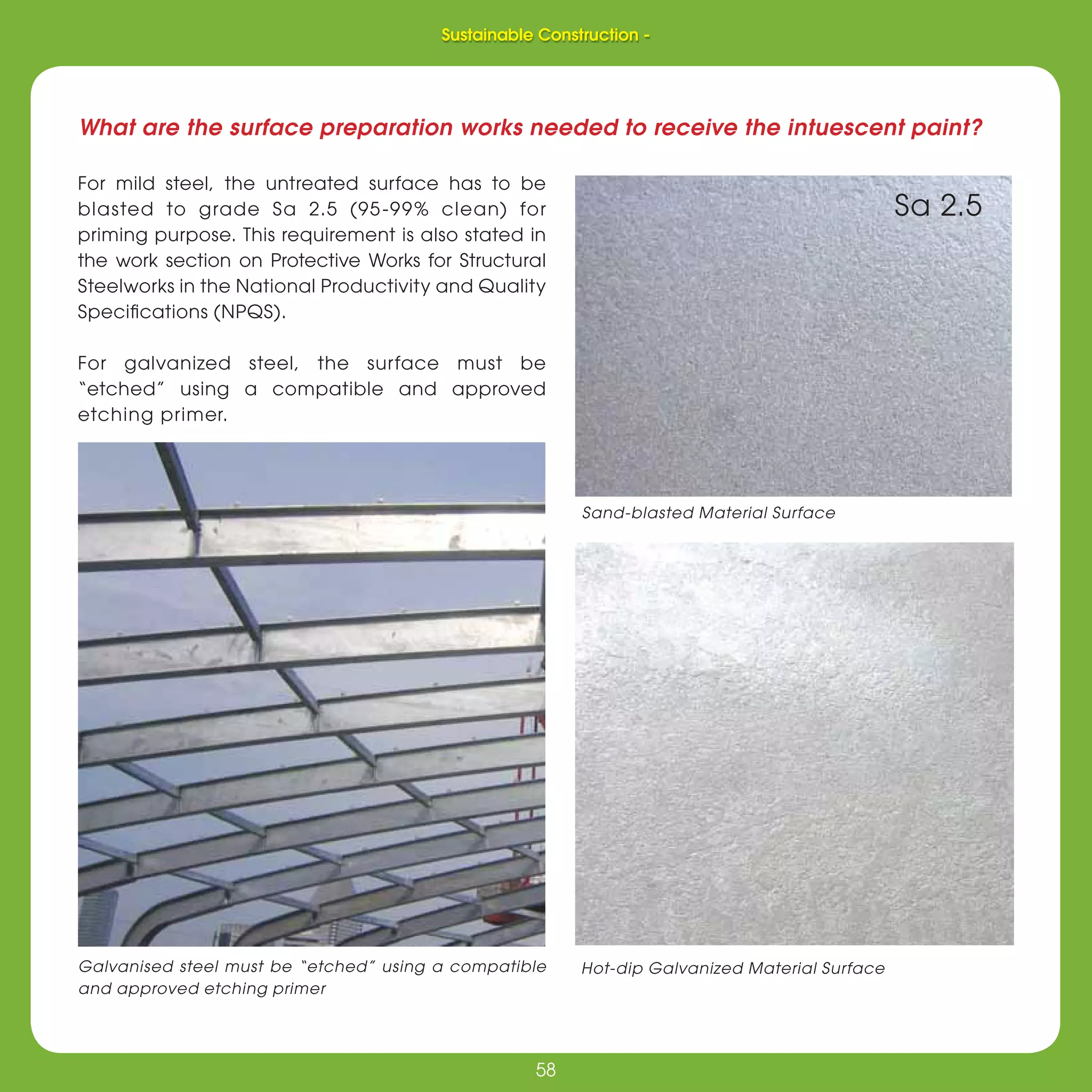

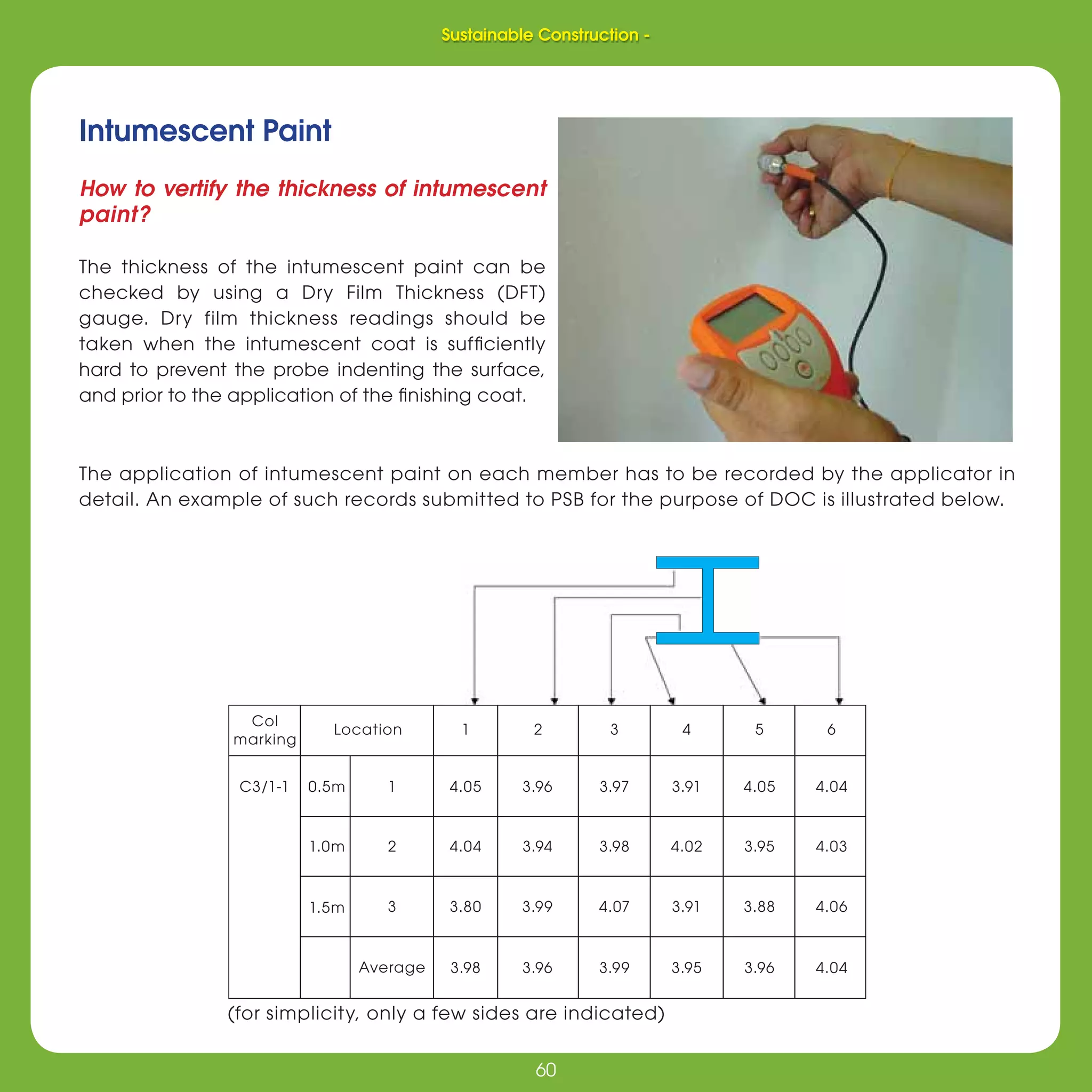

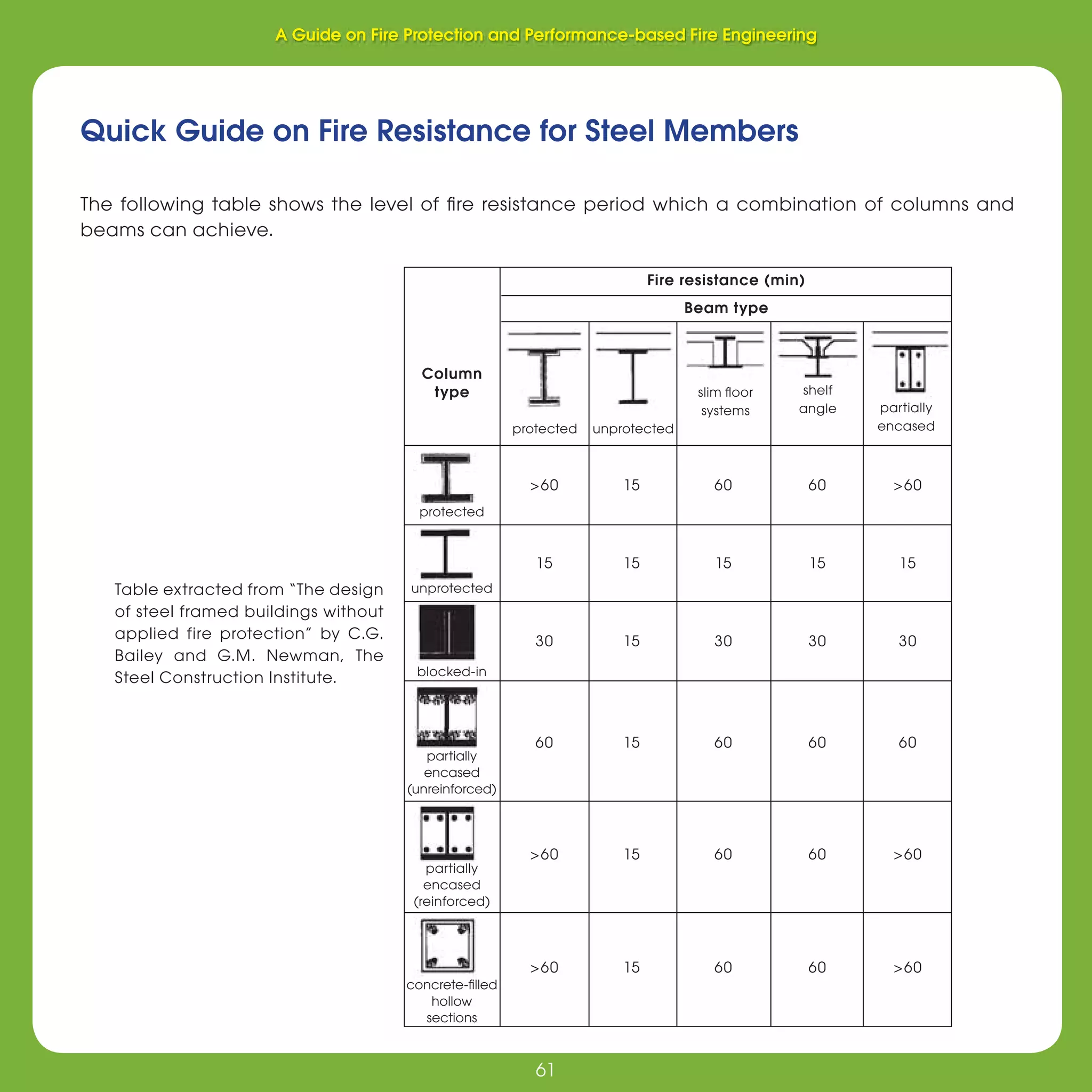

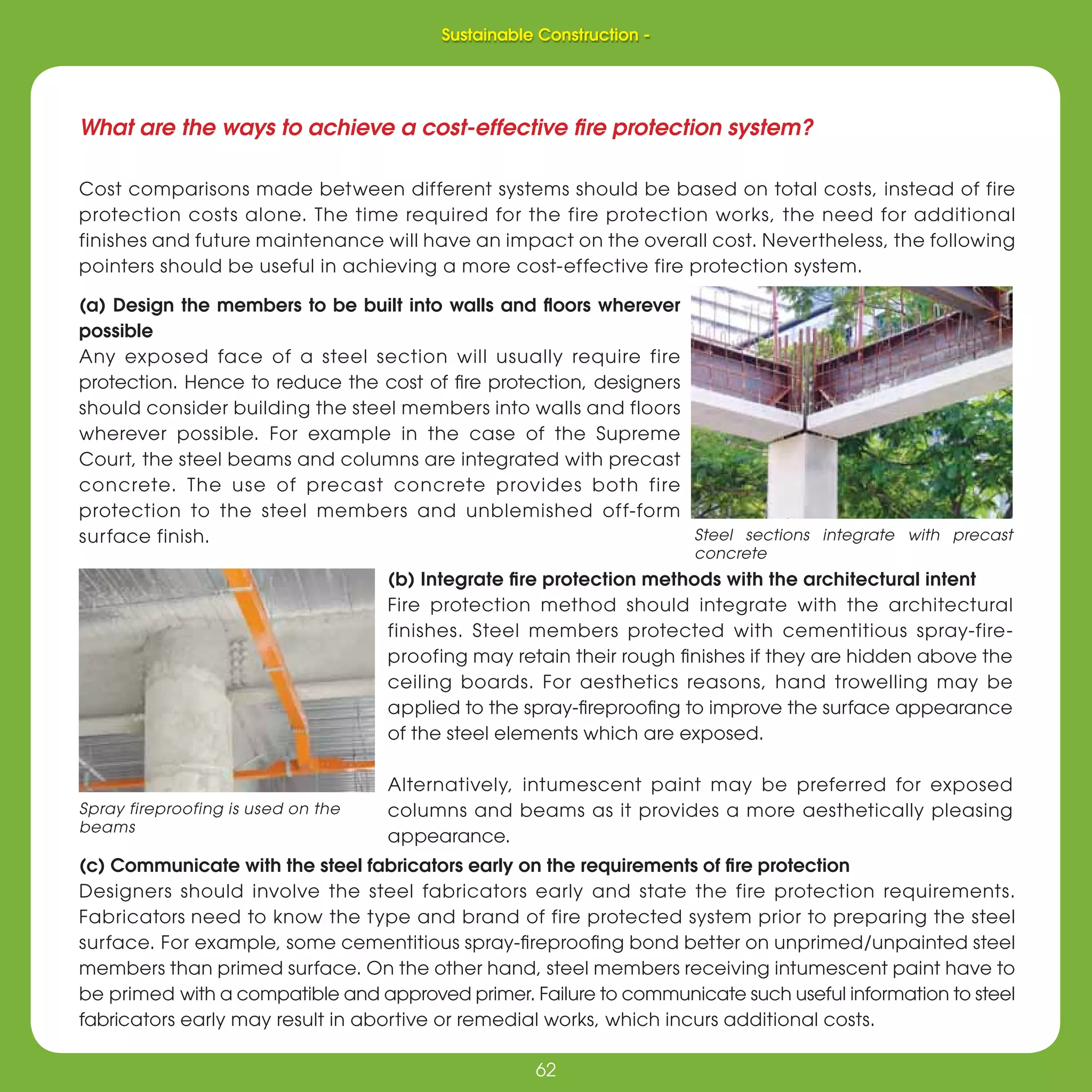

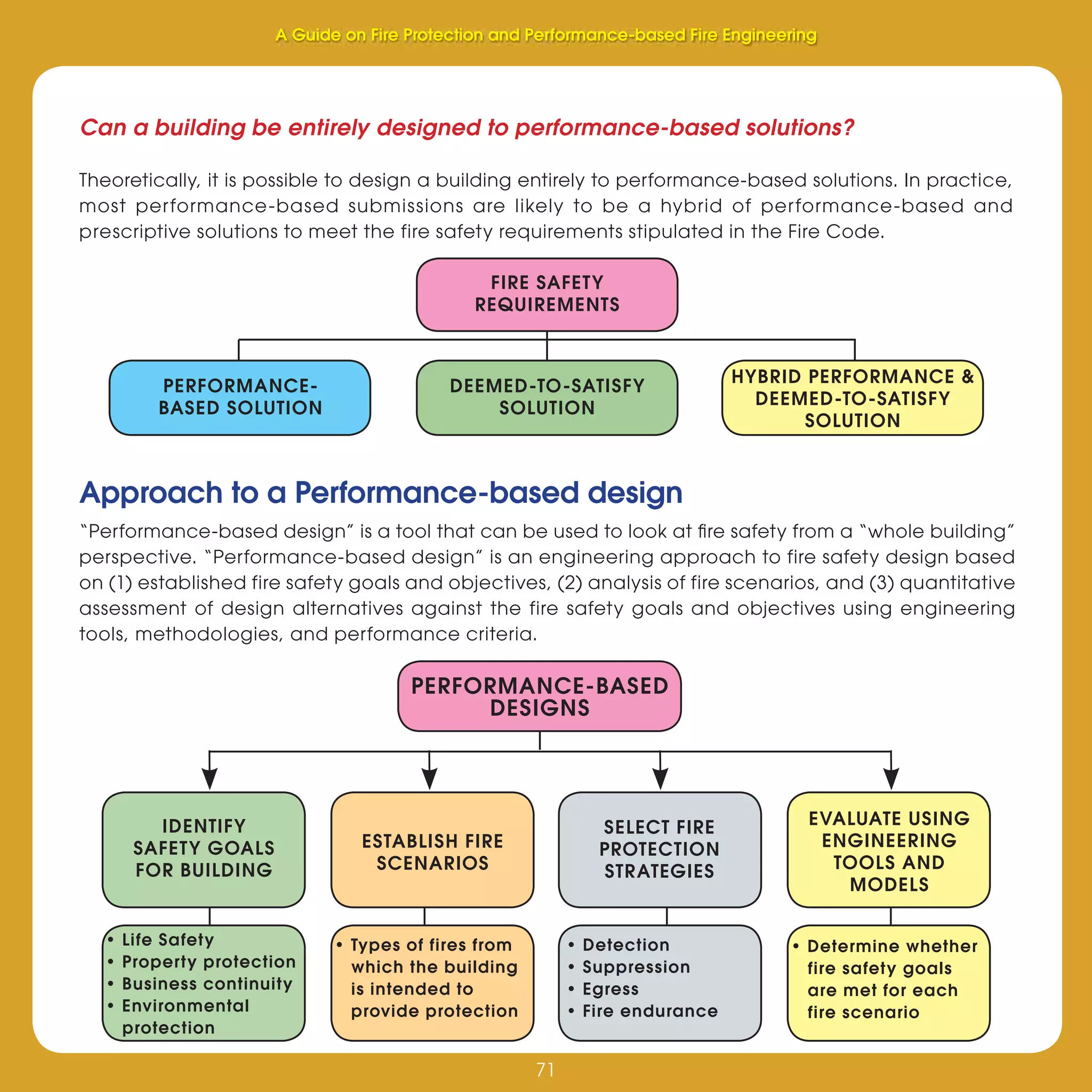

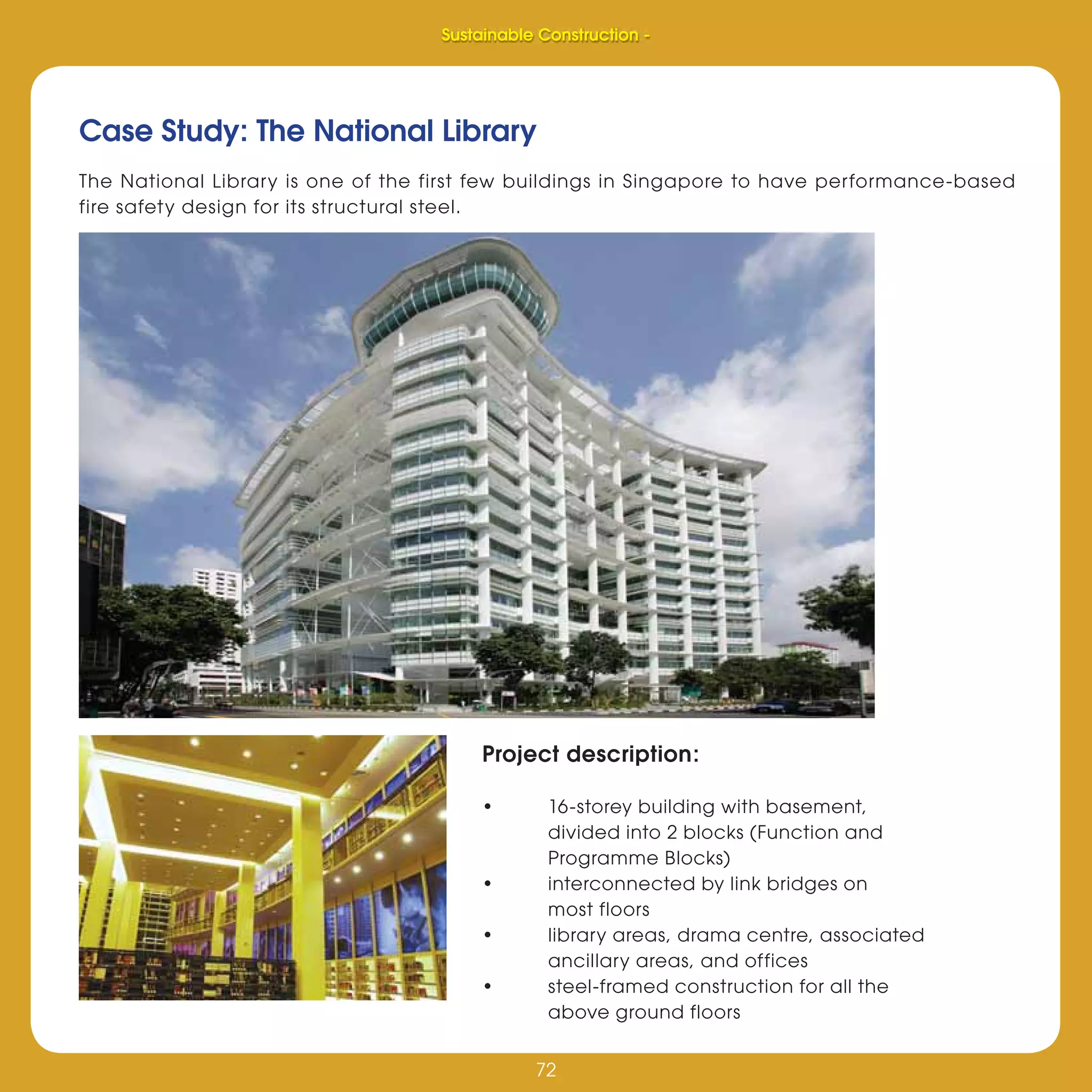

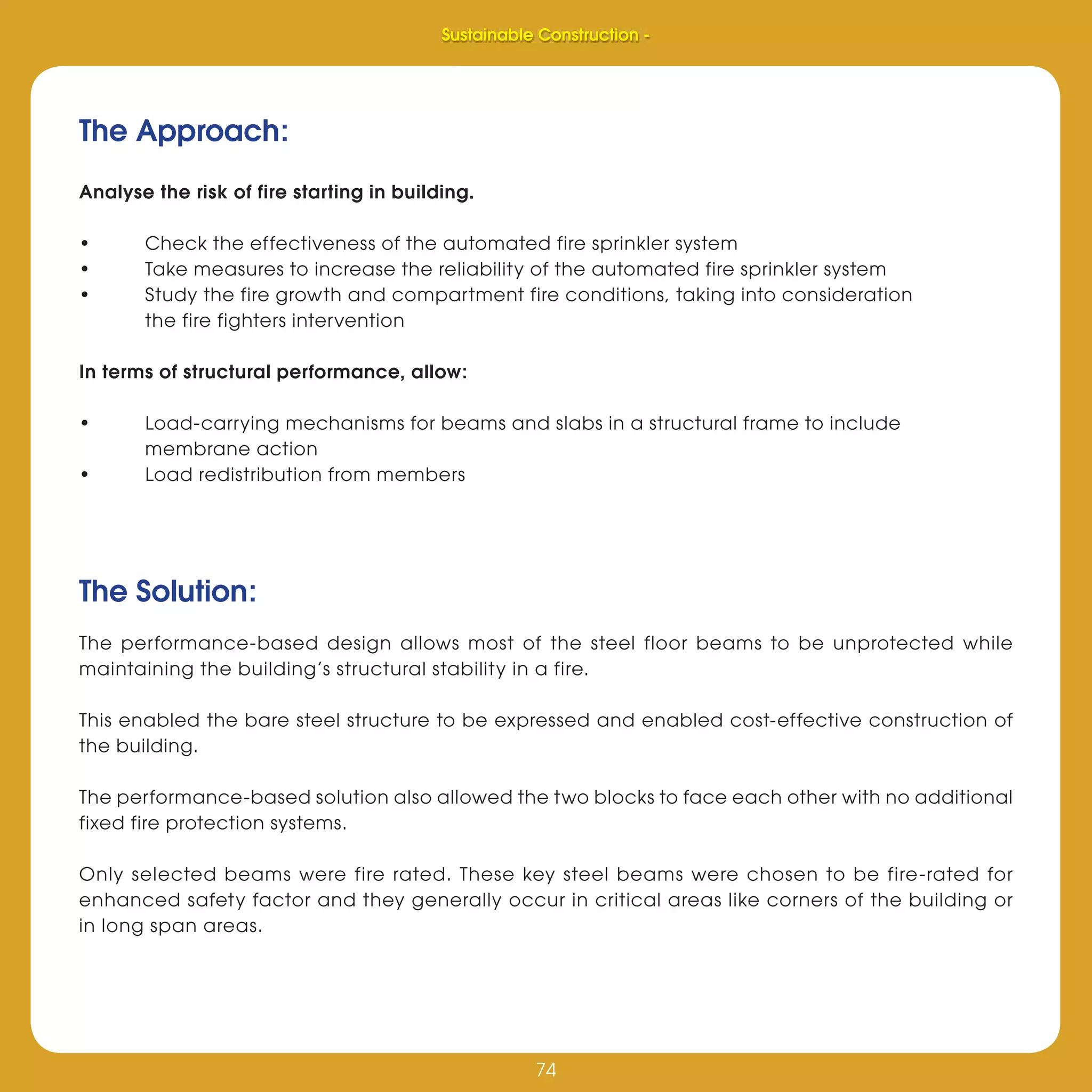

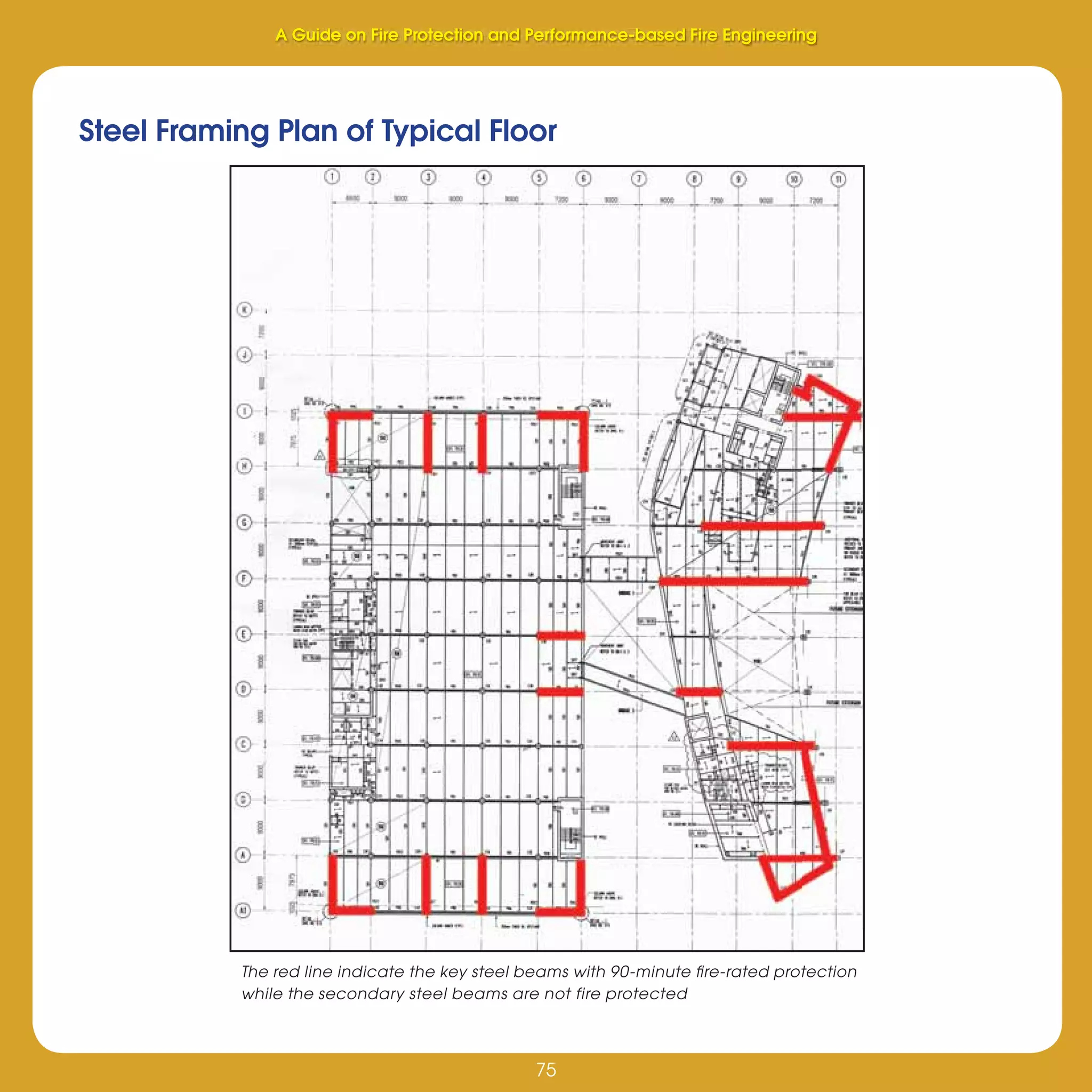

This document provides an overview and guide on fire protection and performance-based fire engineering for sustainable construction. It covers general fire safety requirements, application of building elements like metal decking and drywall systems, different passive fire protection methods, and a performance-based approach to fire safety design. The goal is to promote understanding of fire safety in sustainable construction and serve as a useful reference for building practitioners.