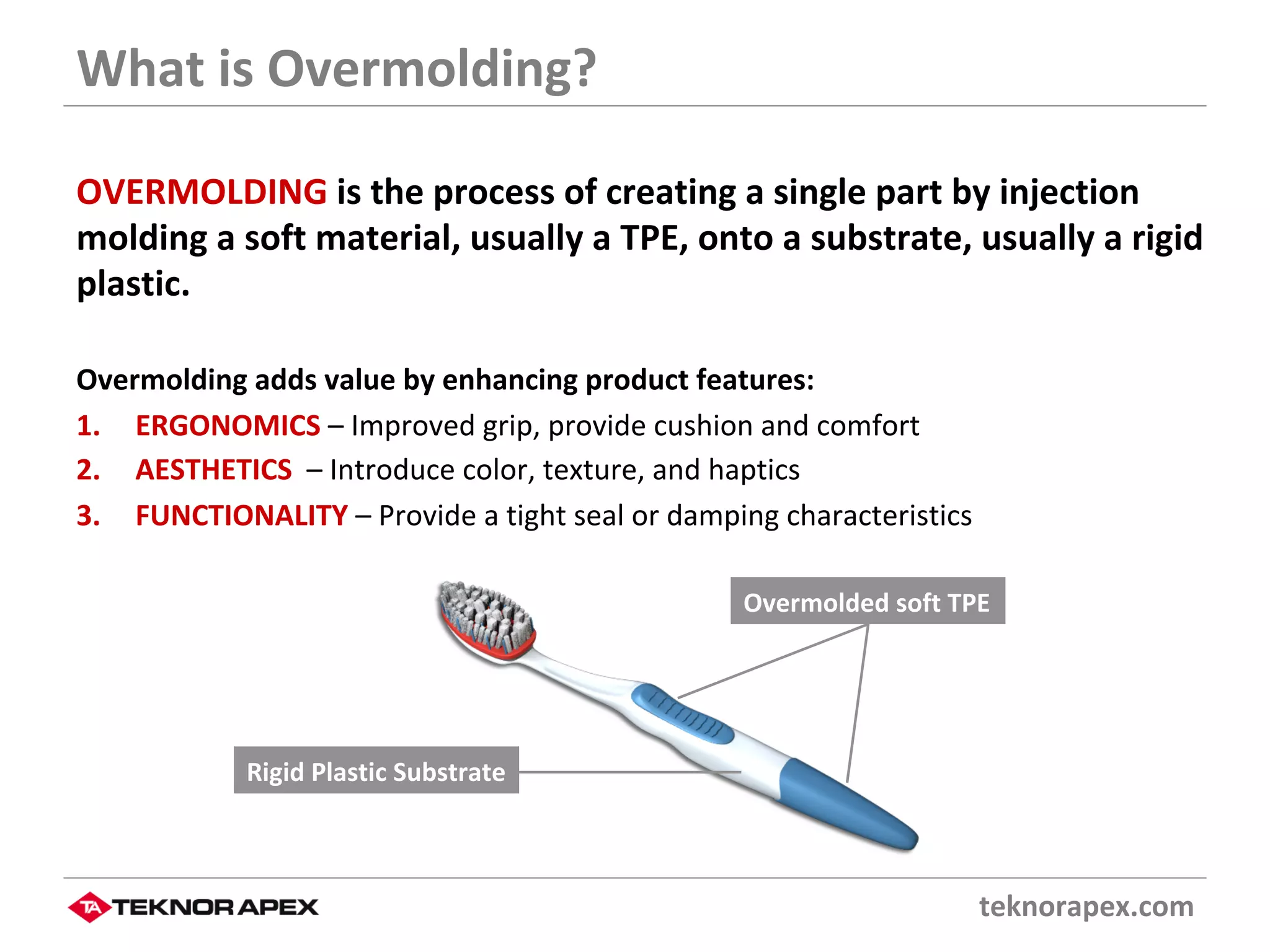

This document provides an overview of overmolding, which is the process of injection molding a soft thermoplastic elastomer (TPE) onto a rigid plastic substrate to create a single part. There are two main overmolding processes: insert molding and multi-shot molding. Choosing the right TPE material is important for achieving good adhesion to the substrate. Factors like material chemistry, part design, processing parameters, and material handling can all influence adhesion. The document outlines best practices for tooling, processing, and material handling to maximize adhesion in overmolded parts.