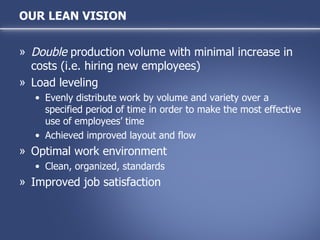

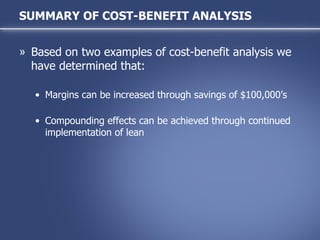

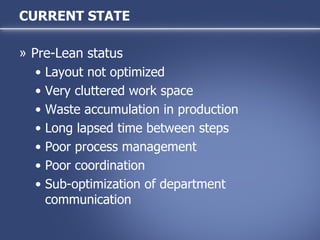

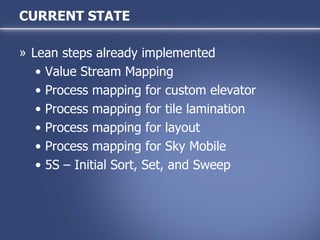

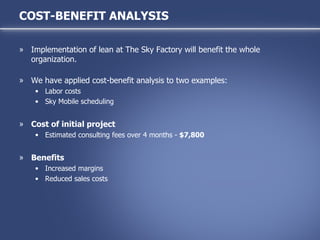

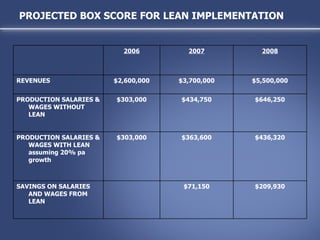

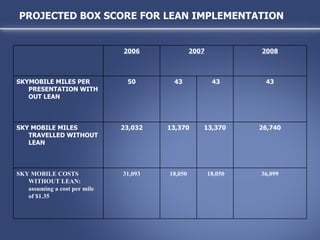

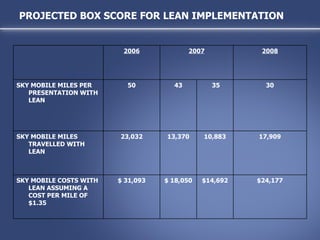

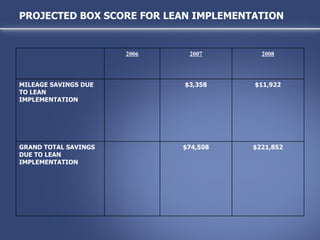

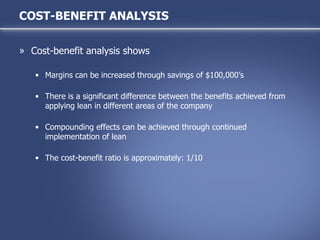

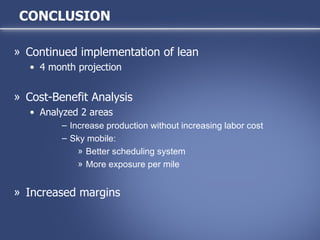

The document discusses implementing lean processes at The Sky Factory to improve efficiency and reduce costs. It describes the current state as having suboptimal processes and layout. Plans are outlined to map current processes, identify lean metrics, make improvements through kaizen events, and conduct ongoing analysis of lean initiatives. Cost-benefit analysis of two areas found lean could increase margins by over $100,000 annually through reduced labor and transportation costs. Continued lean implementation is projected to provide compounding benefits through increased productivity and revenues.