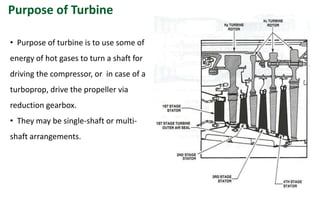

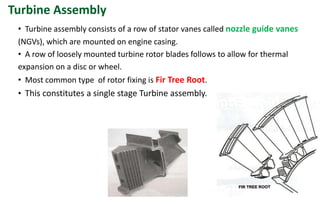

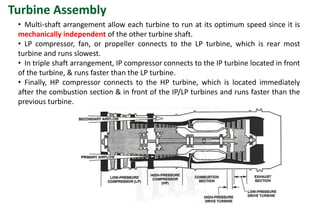

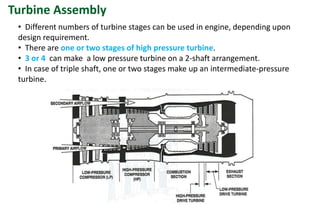

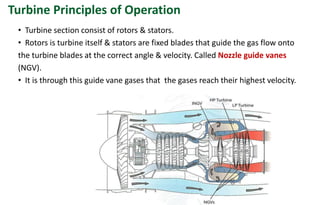

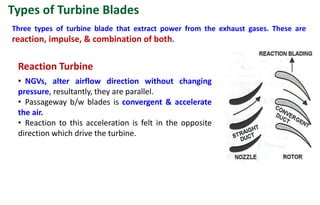

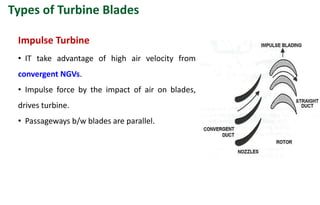

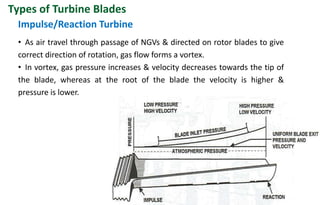

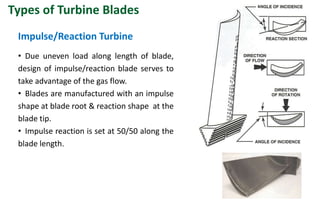

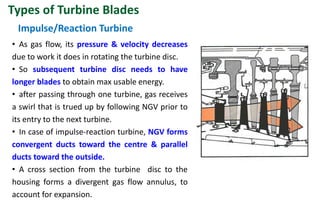

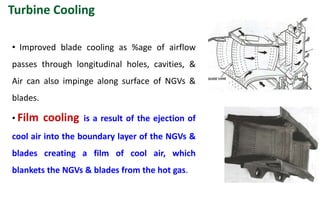

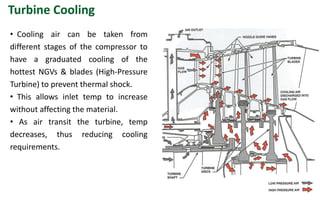

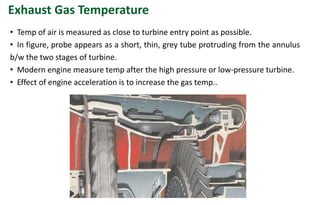

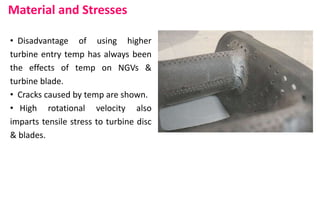

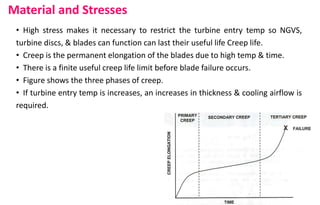

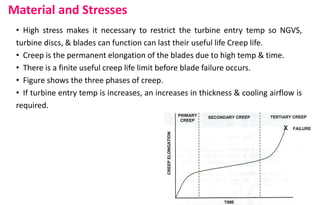

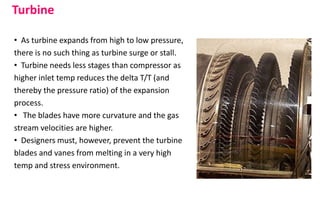

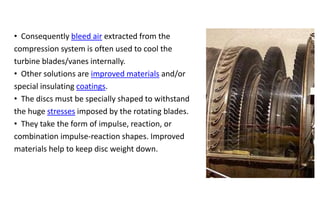

The document outlines the purpose and design of turbine assemblies in engines, including single and multi-shaft arrangements and the roles of high-pressure, intermediate-pressure, and low-pressure turbines. It delves into turbine blade types (reaction, impulse, and combination) and their cooling mechanisms, emphasizing the importance of managing temperature and stress to ensure durability and efficiency. The document also describes the effects of turbine entry temperature on material integrity and the necessity for improvements in materials and cooling techniques to prevent blade failure.