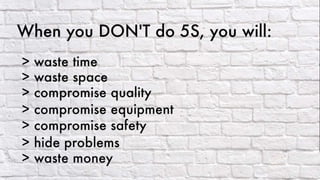

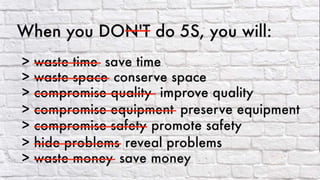

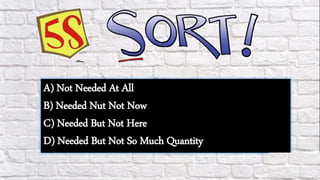

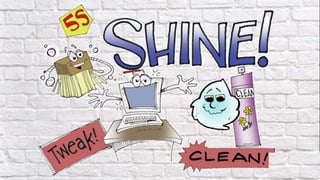

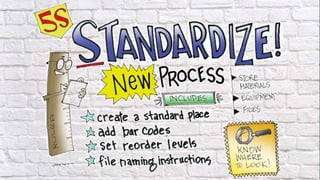

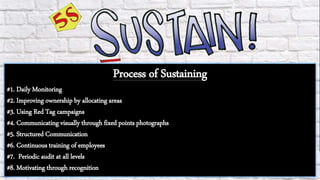

The document discusses the principles of visual management and the 5S system aimed at improving workplace efficiency by organizing items to reduce search time and eliminate waste. It emphasizes the importance of standardizing practices for cleanliness, assigning responsibilities, and ensuring continuous monitoring and training. The benefits of implementing these systems include faster retrieval, corrected abnormalities, and improved overall work efficiency.