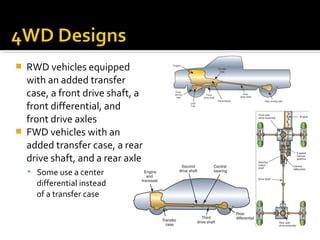

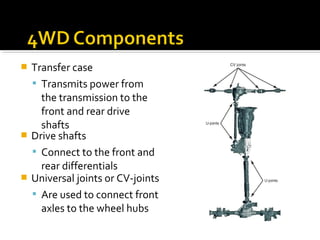

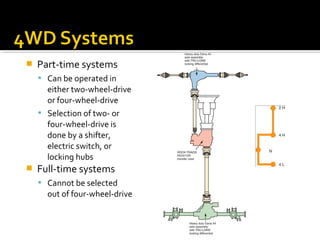

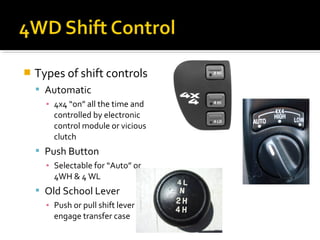

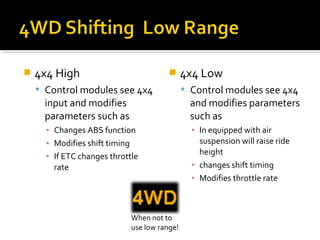

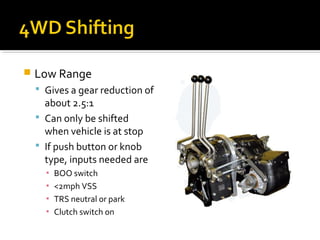

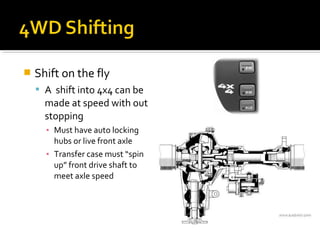

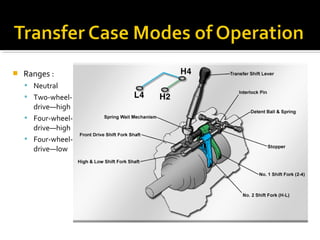

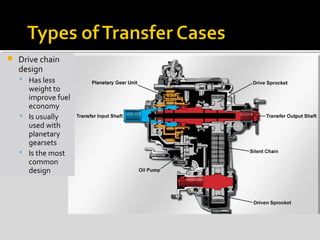

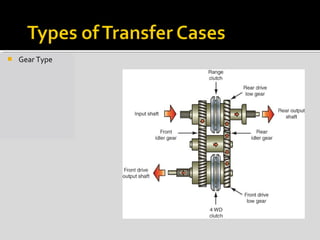

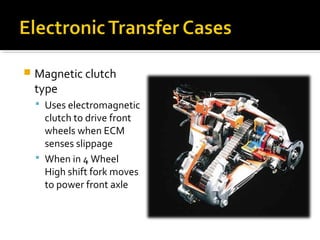

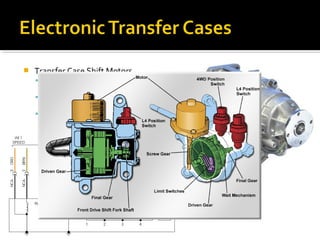

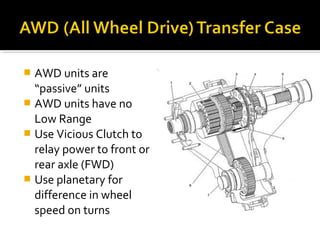

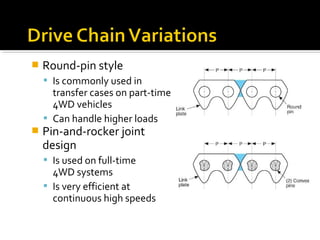

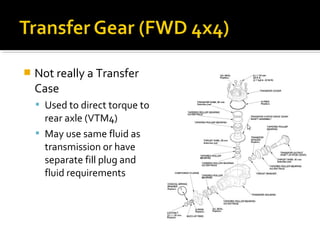

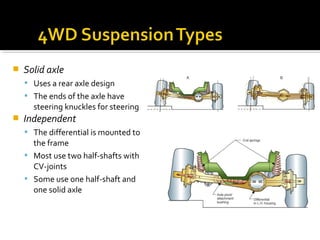

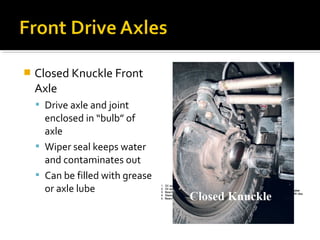

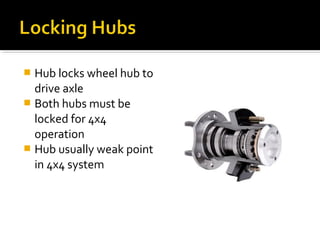

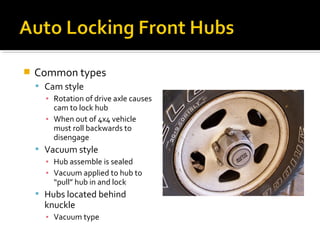

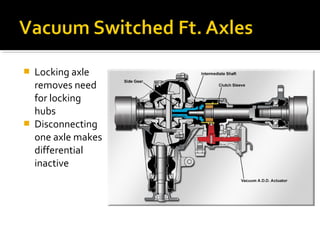

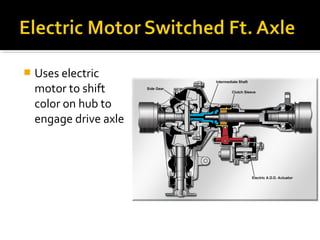

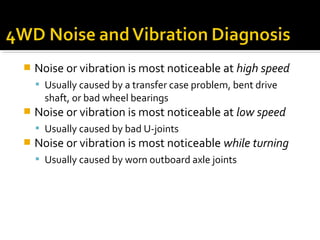

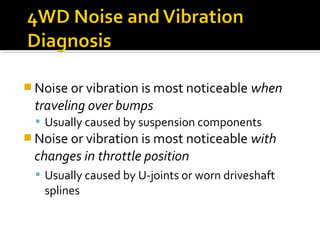

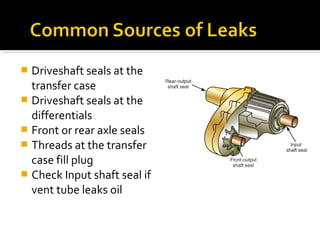

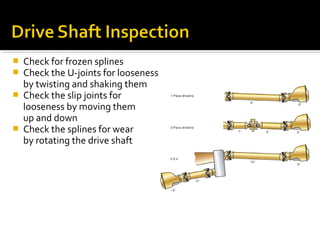

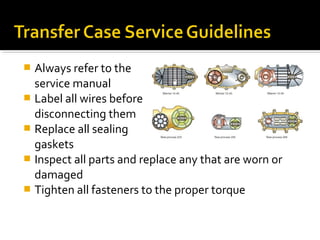

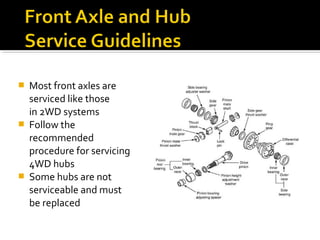

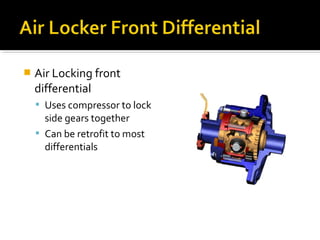

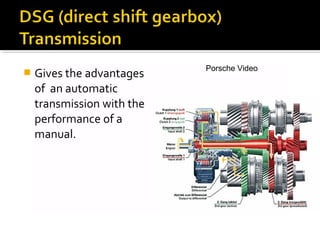

This document discusses all-wheel drive and four-wheel drive systems. It describes the components of 4WD systems including the transfer case, drive shafts, differentials, and axles. It outlines the differences between part-time, full-time, and on-demand 4WD systems. The document provides details on maintenance and troubleshooting 4WD vehicles.