HUBER+SUHNER provides connectivity solutions using three technologies (communication, transportation, industrial) across three markets worldwide. The document discusses the benefits of fiber optic technology, specifically focusing on new low-bend fiber that allows tighter bends without increased loss. It summarizes testing done on low-bend single-mode and multimode fibers from different manufacturers, finding they outperform standard fibers in bend tests and maintain compatibility. While splicing is more challenging, low-bend fibers can overcome higher splice losses. Reliability under tight bends is still uncertain. The technology enables fast, easy installation with high yields.

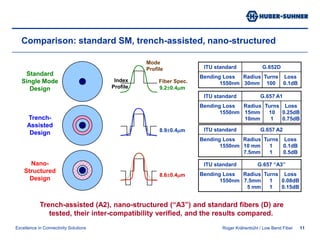

![Roger Krähenbühl / Low Bend Fiber12Mechanical Characteristics: Bending Behaviornano-fibernano-fibertrench-fiber0trench-fiber0.0-1-0.2-0.4-2-0.6-3-0.8Optical Transmission [dB/turn]-1.0Optical Transmission [dB/turn]-4r=7.5 mm-1.2SMFl=1550 nm-5-1.4SMF-1.6-6-1.8Wavelength [nm]-7-2.013001350140014501500155016001650345678910111213Radius [mm]Really advanced technology?Bending tests on CW-E9Both low-bend fibershold up to their claims. Nano- outperforms trench-fiber.](https://image.slidesharecdn.com/41109ineltecenrogerkrhenbhl-110916042408-phpapp02/85/Low-Bend-Fiber-Technology-14-320.jpg)

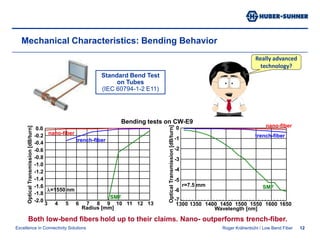

![up to 450N/cm,1min each, l = 1550nm0.50.4SMF0.3trench-fiber0.2nano-fiber0.1Change of Attenuation [dB]0.0500Compressive Stress [N/cm]-0.1400300200100013579111315171921232527Time [min]Temperature Cycling CWJH-H27 Crush tests on CW-E91412SMF10Insertion Loss Variation [dB] 8642080trench-fibernano-fiber604020Temperature [C]0-20-40-60l=1550 nm0102030405060Time [h]Roger Krähenbühl / Low Bend Fiber13Mechanical Characteristics: Crush Tests, Temperature CyclingLow-bend fibers perform better under crush and temperature cycling tests than SMF.](https://image.slidesharecdn.com/41109ineltecenrogerkrhenbhl-110916042408-phpapp02/85/Low-Bend-Fiber-Technology-15-320.jpg)

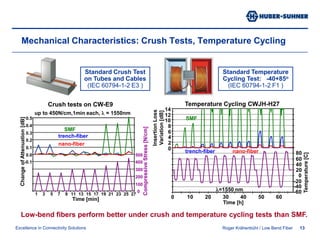

![Roger Krähenbühl / Low Bend Fiber14Splicing Tests: Performance ComparisonSMF - trench-fiberSMF - nano-fiberEase of Splicing and splice performance testing: All combinations for SMF, trench-, and nano-structured fiberEasy handling ?Loss Distribution per Splice 60Mean:0.01 dB0.03 dB0.08 dB50SMF - SMF4030%201000.150.010.030.050.070.080.100.120.140.000.020.040.060.090.110.13Splice Loss [dB]Splicing of fibers with low-bend SM fibers needed much more exploration of process parameter than with the standard SM fiber types. They have slightly higher splice losses, maybe due to higher core ex-centricity (less experienced, larger fabrication tolerance chain)Low-bend fibers are well suited as higher splice loss can be over-compensated](https://image.slidesharecdn.com/41109ineltecenrogerkrhenbhl-110916042408-phpapp02/85/Low-Bend-Fiber-Technology-16-320.jpg)

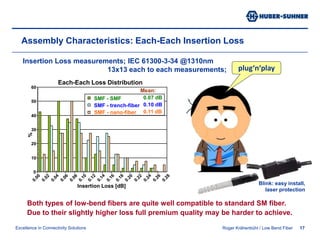

![Roger Krähenbühl / Low Bend Fiber17Assembly Characteristics: Each-Each Insertion LossEach-Each Loss Distribution60SMF - SMF50SMF - trench-fiberSMF - nano-fiber4030%201000.000.020.040.060.080.100.120.140.160.180.200.220.240.260.28Insertion Loss [dB]Insertion Loss measurements; IEC 61300-3-34 @1310nm 13x13 each to each measurements; plug‘n‘playMean:0.07 dB0.10 dB0.11 dBBlink: easy install, laser protectionBoth types of low-bend fibers are quite well compatible to standard SM fiber. Due to their slightly higher loss full premium quality may be harder to achieve.](https://image.slidesharecdn.com/41109ineltecenrogerkrhenbhl-110916042408-phpapp02/85/Low-Bend-Fiber-Technology-19-320.jpg)

![Roger Krähenbühl / Low Bend Fiber19Fiber ReliabilityStress-behavior according to IEC 62048Failure Probability in 20 Years for Different Lengths1.E-08High yield10cm1.E-071.E-0610m1.E-051000mFailure Probability1.E-041.E-031.E-021.E-011.E+002468101214161820222426283032Bend Radius [mm]There is no physical reason for another lifetime behavior for the different types of fiber (stress distribution across fiber is the same).To reach similar reliability as for a LISA fiber management rack (r=30mm, >1000m bend fiber) only 5cm can be bend at r=10mm and only 1cm at r= 5mm.](https://image.slidesharecdn.com/41109ineltecenrogerkrhenbhl-110916042408-phpapp02/85/Low-Bend-Fiber-Technology-21-320.jpg)