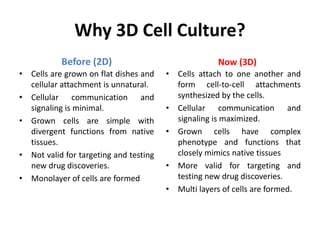

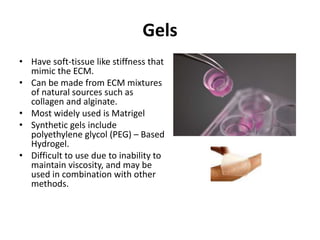

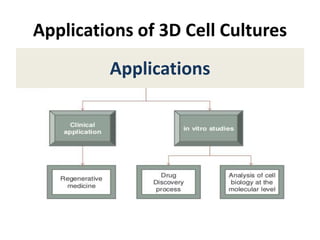

This document discusses 3D cell culture techniques. It defines 3D cell culture as permitting biological cells to grow and interact in all three dimensions, mimicking their natural environment. This is an improvement over 2D cultures where cells grow unnaturally. The document describes various 3D culture methods including scaffold-based techniques using polymeric scaffolds or biological scaffolds, and non-scaffold methods like hanging drop plates, spheroid plates, microfluidics, and gels. It also discusses bioreactors and lists applications of 3D cultures.