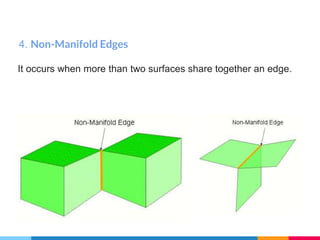

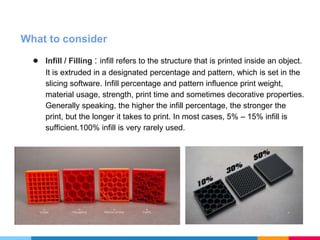

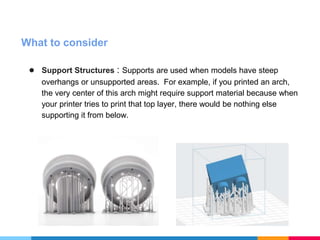

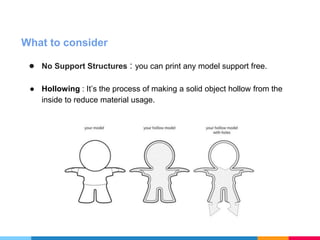

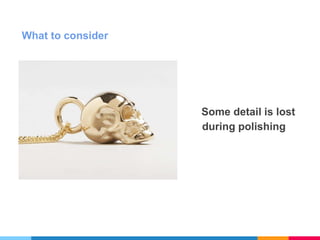

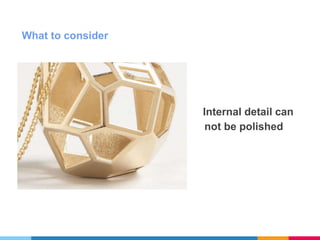

The document discusses essential considerations for creating 3D models suitable for printing, highlighting common printability issues such as solidity, flipped faces, and wall thickness. It also compares various materials like ABS/PLA plastics, UV-cured resin, nylon, and full-color sandstone, detailing their uses, benefits, and limitations. Key printing concepts such as support structures, infill percentages, and post-processing requirements are emphasized for successful 3D printing.