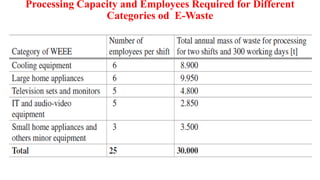

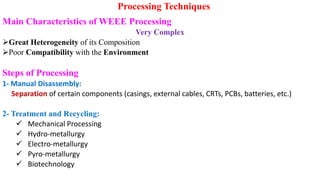

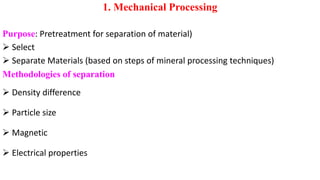

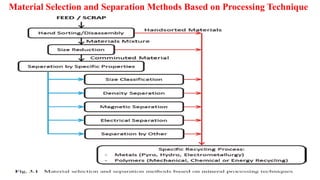

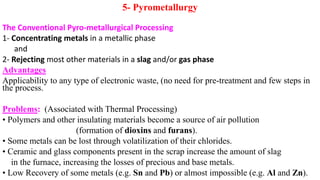

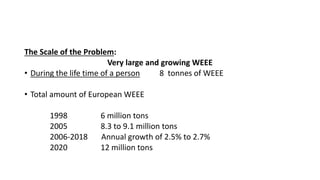

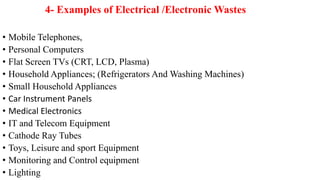

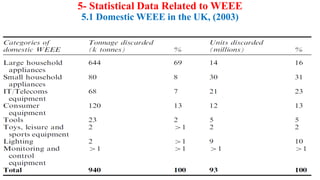

The document covers the management of electronic waste (e-waste), highlighting the significant growth in e-waste production and the challenges associated with its recycling and recovery. It addresses sustainability, various types of e-waste, statistical data, European legislation, and obligations of manufacturers regarding hazardous materials and waste management. Additionally, it details e-waste processing techniques and methodologies, including mechanical, hydrometallurgical, and pyrometallurgical processes.

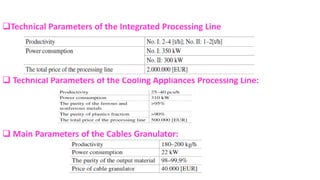

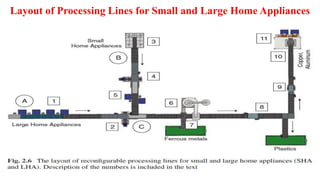

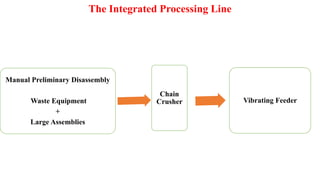

![The Integrated Processing Line

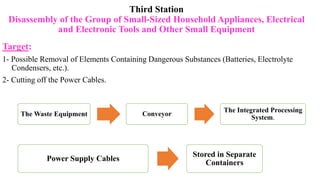

Target:

➢Preparation of high-purity concentration of waste fractions of:

o Metallic – (Ferrous and Non-Ferrous) Wastes

o Plastics.

Elements of the Integrated Processing Line:

• Line No. I: For Large Home Appliances and Heavy Equipment

• Capacity: 2–4 [tonnes/h]

• Equipment:

• Belt conveyors and vibratory feeders

• Chain crusher

• Dust extraction systems

• Pneumatic sieves

• Separators: magnetic, eddy current, and electrostatic](https://image.slidesharecdn.com/ilovepdfmerged-200809102645/85/39-_-28-320.jpg)

![The Integrated Processing Line

Line No. II: For Small or Medium Equipment

&

Crush Residues from Line No. I

Capacity: 1–2 [tonnes/h]

Equipment:

o Belt conveyors and vibratory feeders

o Hammer mill

o Screening separators

o Electrostatic, magnetic, and eddy current separators.](https://image.slidesharecdn.com/ilovepdfmerged-200809102645/85/39-_-30-320.jpg)