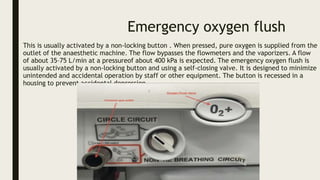

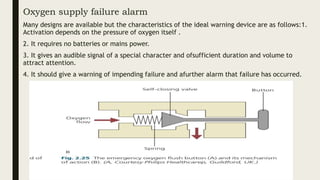

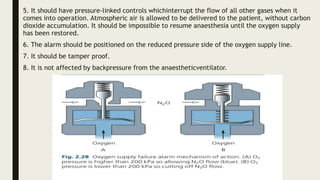

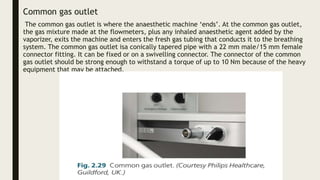

The emergency oxygen flush provides a high flow of pure oxygen from the anaesthetic machine bypassing the flowmeters and vaporizers, expected to be around 35-75 L/min at 400 kPa pressure. It is activated by a non-locking button to minimize unintended use but puts patients at risk of barotrauma if used inappropriately. The oxygen supply failure alarm ideally activates based only on oxygen pressure, requires no power, and gives audible warnings of impending and actual failure while interrupting other gas flows and allowing atmospheric air delivery until oxygen is restored.