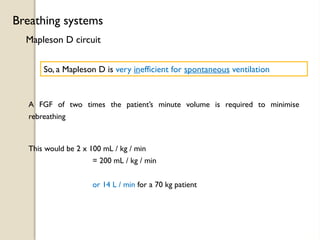

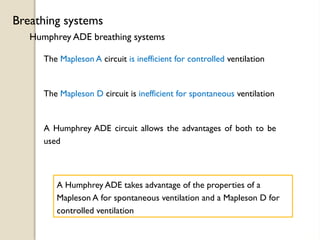

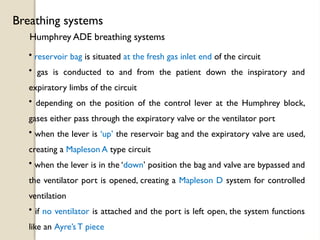

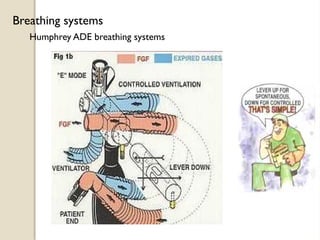

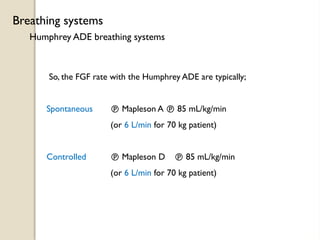

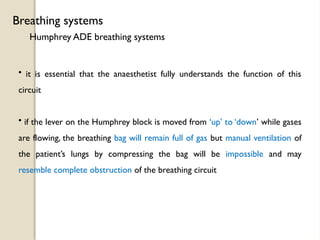

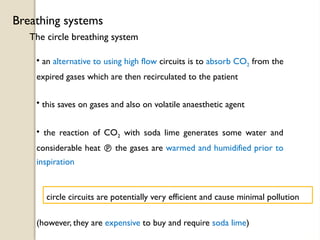

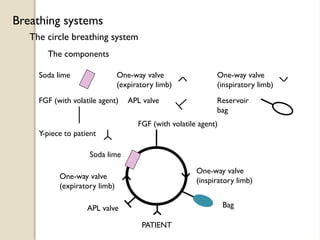

The document provides a comprehensive overview of various breathing systems used in anesthesia, detailing components, efficiencies, and considerations for ventilation. It includes discussions on Mapleson systems, rebreathing concepts, and the advantages of circle systems that recirculate gases to minimize waste. The objective is to inform anesthesiologists about system selection to optimize patient care and ventilation efficiency.

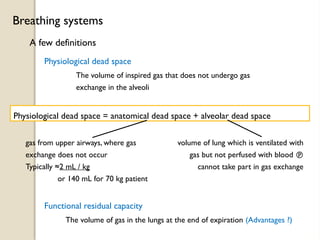

![A few definitions

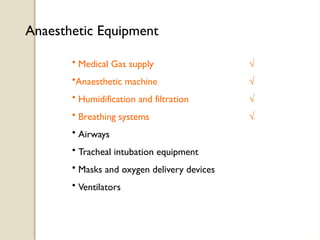

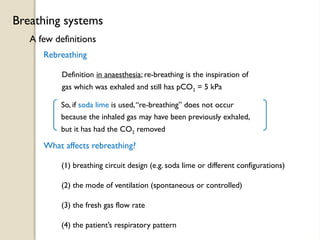

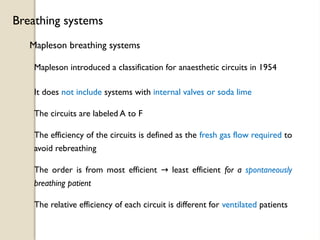

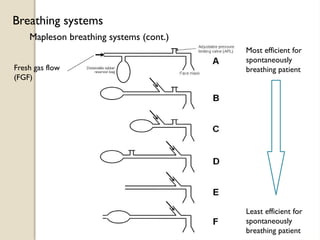

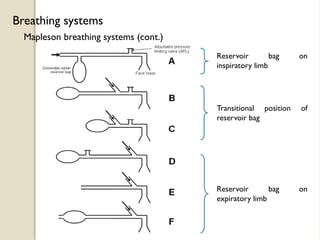

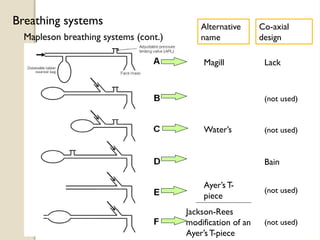

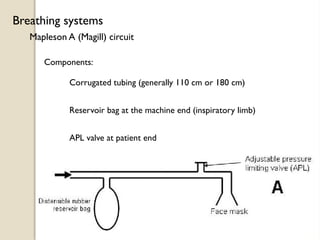

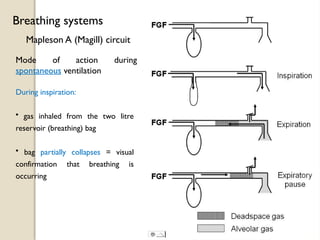

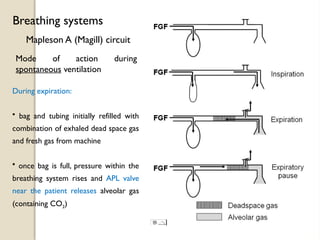

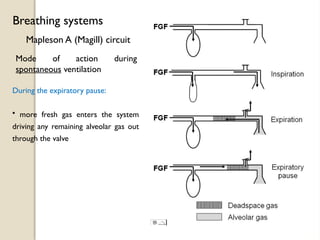

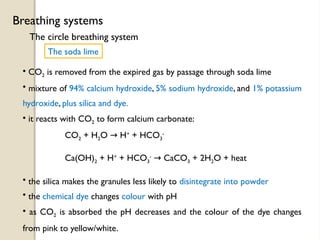

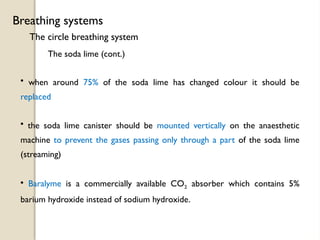

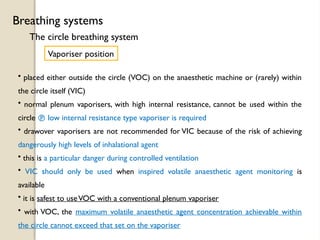

Breathing systems

Tidal volume

Minute volume

The volume of gas inspired & expired with each breath

Typically ≈7 mL / kg

(or 500 mL for 70 kg patient)

The total volume breathed in a minute

Typically ≈100 mL / kg / min

(or 7000 mL / min for 70 kg patient)

Alveolar minute volume

The volume undergoing gas exchange per minute

( = RR x [tidal vol – dead space] )

Typically ≈70 mL / kg / min

(or 5000 mL / min for 70 kg patient)](https://image.slidesharecdn.com/3-241124083054-444343e1/85/3-different-types-of-breathing-system-pptx-5-320.jpg)

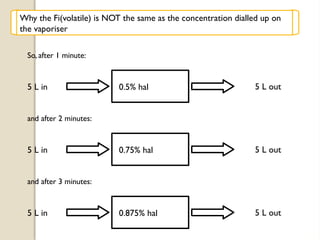

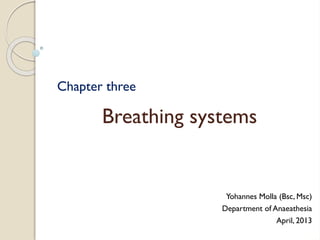

![5 L in 5 L out

5 L volume

Let the FGF = 5 L / min

and the circle circuit volume = 5 L

In one minute:

This is like diluting the circle circuit (5 L) with a further 5 L every minute

Suppose the dialed [halothane] = 1 % (the vaporiser setting)

5 L in

(1 % Hal)

5 L out

(0.5%Hal)

5 L volume + 5L

FGF

These are approximately

correct

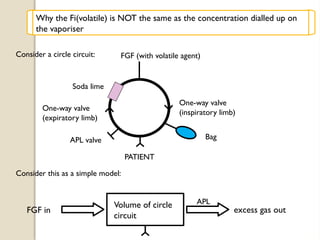

Why the Fi(volatile) is NOT the same as the concentration dialled up on

the vaporiser](https://image.slidesharecdn.com/3-241124083054-444343e1/85/3-different-types-of-breathing-system-pptx-53-320.jpg)